A surface treatment process for 3D printed implants

A 3D printing and surface treatment technology, applied in the direction of surface reaction electrolytic coating, dental implants, additive processing, etc., can solve the problem of decreased osseointegration and mechanical properties of oral implants, uncontrollable pore structure and pore size, and deep holes. Unable to completely remove impurities and other problems, to achieve the effect of increasing ion exchange speed, suppressing stress shielding, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A surface treatment process for 3D printing implants, comprising the following steps:

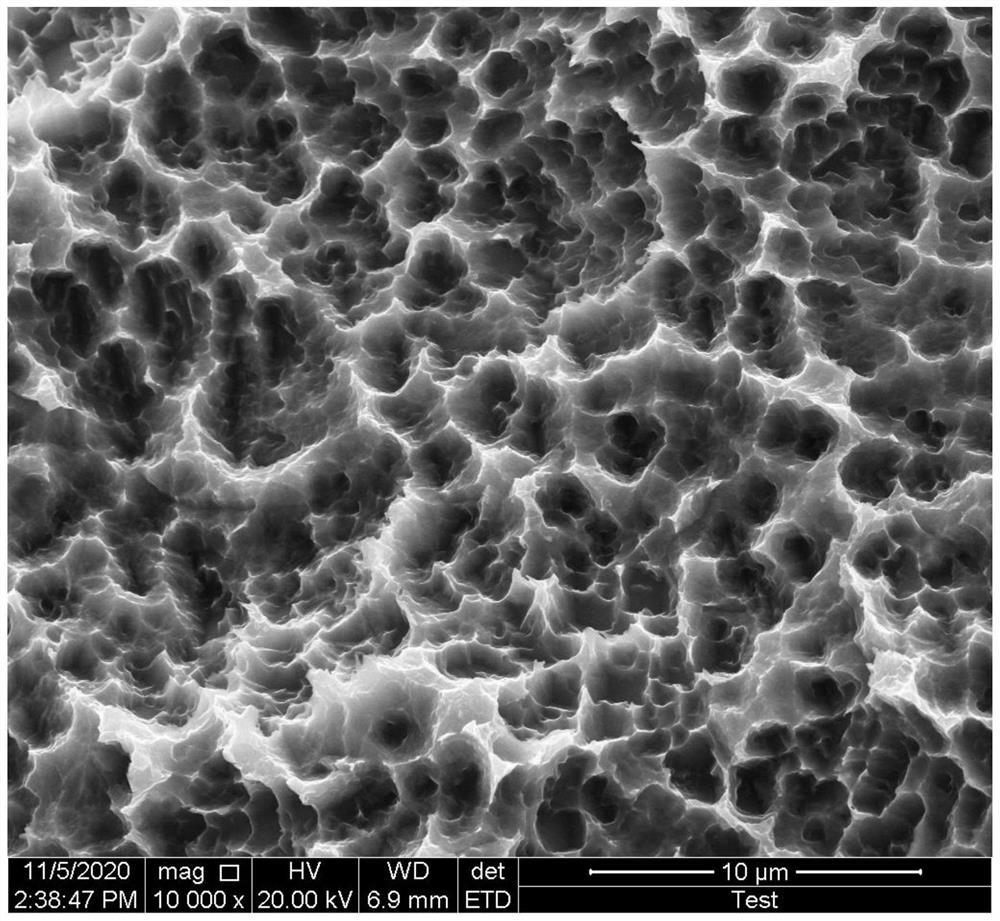

[0040] S1: The printing process of the 3D printed implant: (1) Design the 3D model of the implant with a pore structure; (2) Slice the 3D model, the slice thickness is 28 μm, and plan the scanning path; use the nine-square grid method for partition scanning, and the area size is 2× 2mm, the scanning direction is deflected by a certain angle when scanning different layers, and the deflection angle is set to 37°. (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the forming chamber. Repeated replacements in this way, the final oxygen content is less than 100ppm, and the pressure is 30mbar. Argon environment; when printing, the substrate is preheated through the preheating function, the preheating temperature is 100°C, after the substrate is preheated, a layer of new...

Embodiment 2

[0044] A surface treatment process for 3D printing implants, comprising the following steps:

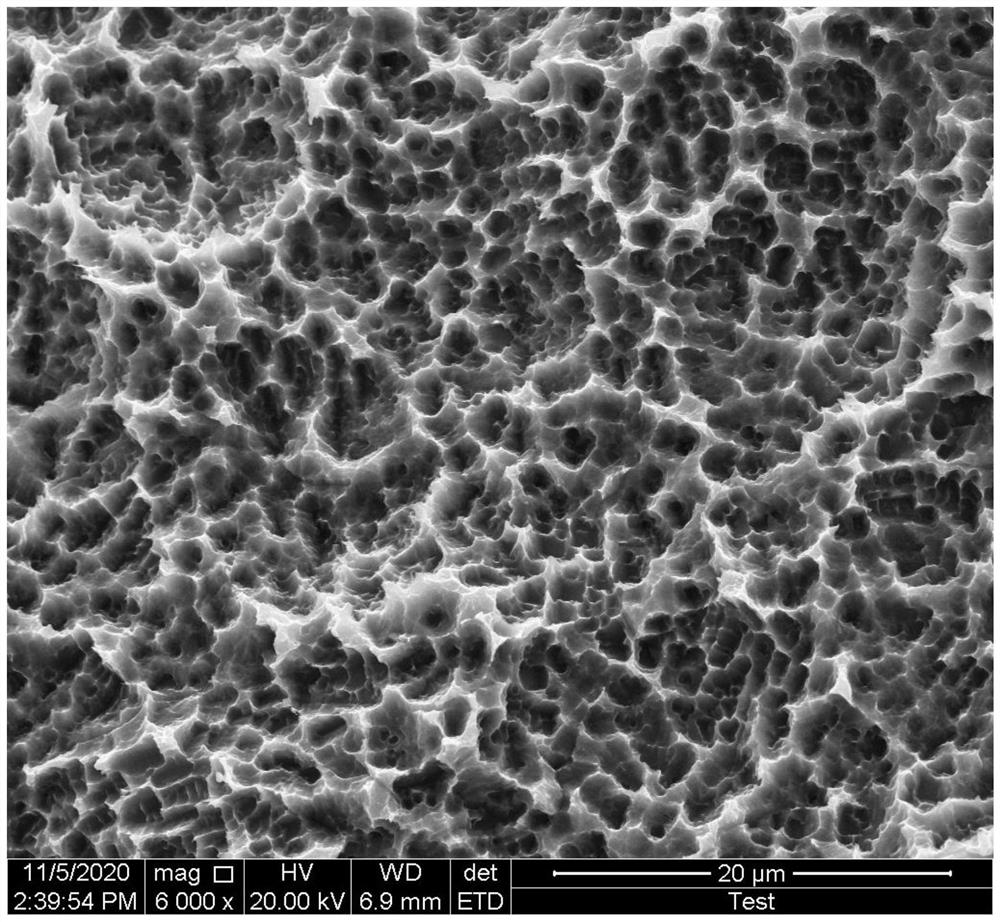

[0045] S1: The printing process of the 3D printed implant: (1) Design the 3D model of the implant with a pore structure; (2) Slice the 3D model, the slice thickness is 22 μm, and plan the scanning path; use the nine-square grid method for partition scanning, the area size is 2× 2mm, the scanning direction is deflected by a certain angle when scanning different layers, and the deflection angle is set to 37°. (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the forming chamber. Repeated replacement in this way, the final oxygen content is less than 100ppm, and the pressure is 18mbar. Argon environment; when printing, the substrate is preheated through the preheating function, and the preheating temperature is 100°C. After the substrate is preheated, a layer of new ...

Embodiment 3

[0049] A surface treatment process for 3D printing implants, comprising the following steps:

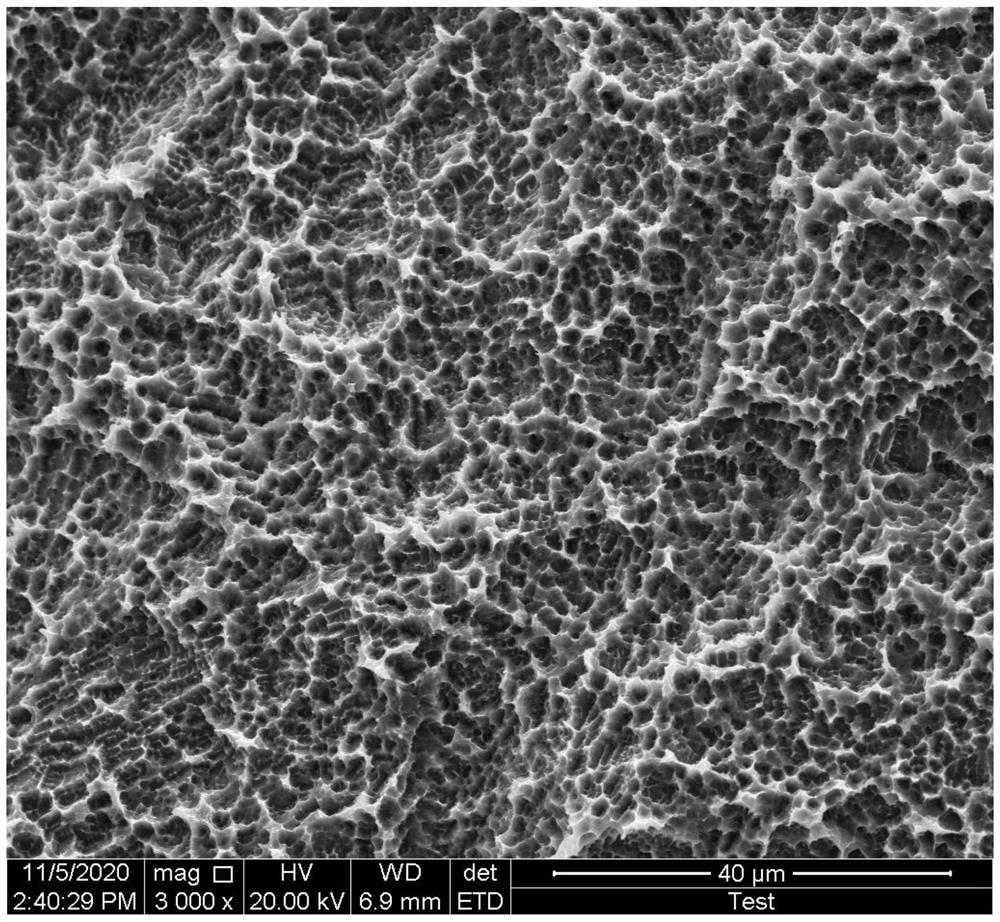

[0050] S1: The printing process of 3D printed implants: (1) Design the 3D model of the implant with a pore structure; (2) Slice the 3D model, the slice thickness is 24 μm, and plan the scanning path; use the nine-square grid method for partition scanning, and the area size is 2× 2mm, the scanning direction is deflected by a certain angle when scanning different layers, and the deflection angle is set to 37°. (3) The selective laser melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the forming chamber. Repeated replacement in this way, the final oxygen content is less than 100ppm, and the pressure is 32mbar. Argon environment; when printing, the substrate is preheated through the preheating function, and the preheating temperature is 100°C. After the substrate is preheated, a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com