Lamellar TS-1 molecular sieve as well as preparation method and application thereof

A TS-1, flake technology, applied in the field of flake TS-1 molecular sieve, can solve the problems of cumbersome steps, high production cost, complicated process and the like of flake MFI molecular sieve, and achieves simple and feasible preparation method, low cost and synthetic cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of amorphous titanium dioxide / silicon

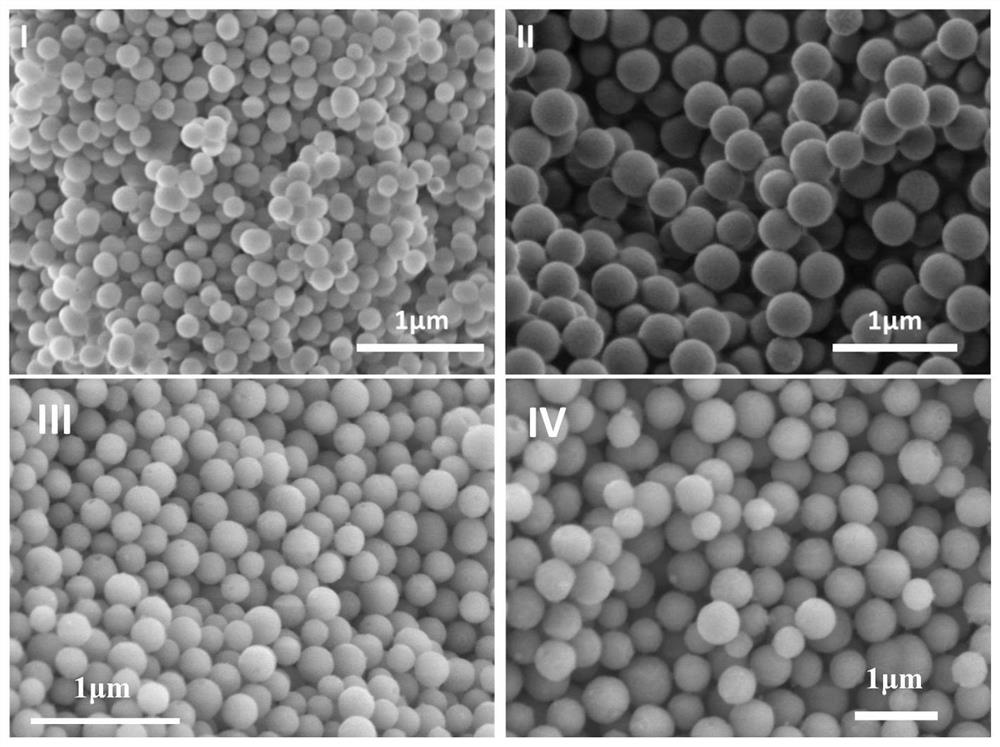

[0052] At 50 ° C agitation conditions, 0.20 g of hexadalkyltrimethyla bromide (structural guide) was dissolved in 60 ml of deionized water and ethanol solution, and then the pH of the ammonia water regulated solution was added to the solution. 1.0 g of orthosilicate and 0.05 g of tetrabutyl titanate were added, and stirring was continued for 2 h. The product was filtered, washed, washed, and then dried, and the structural guiding agent was removed by calcitating 6 hours at 550 ° C to give a white powder, labeled a sample I. SEM results show that the obtained product is 50-200 nm spherical material, the particle size is uniform, and the dispersibility is good. According to Table 1 Adjust the pH of the combined process and the addition of the added amount of orthosilicate and butyl butyl butyl addition, the resulting product can be changed, the resulting sample number and performance parameters are shown in Table...

Embodiment 2

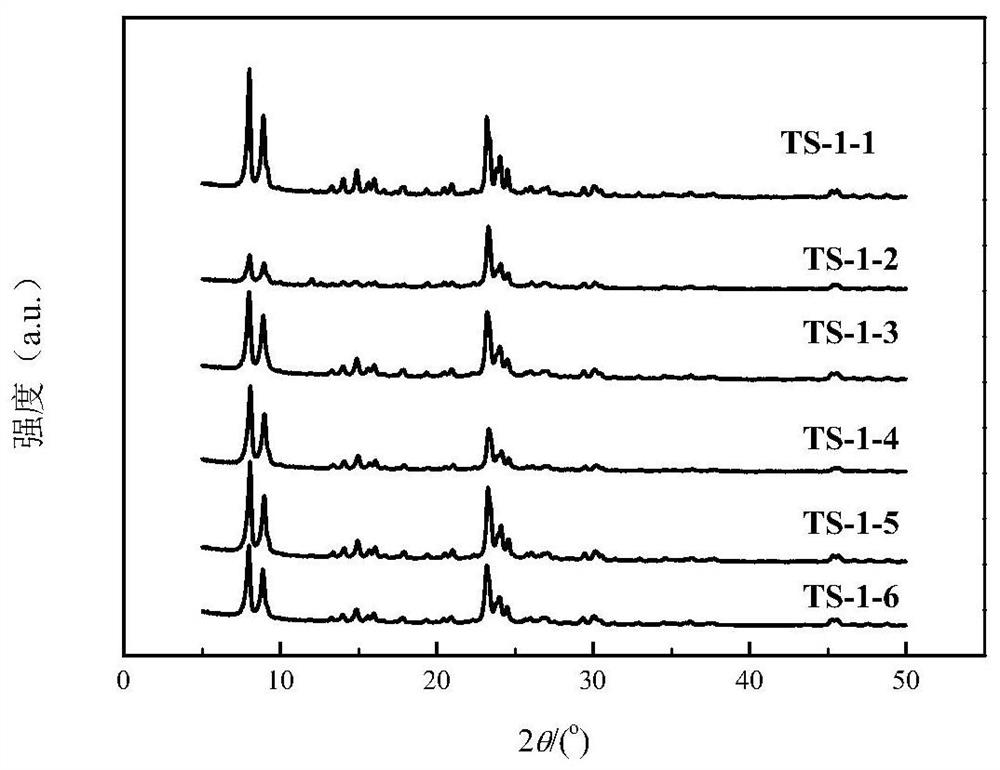

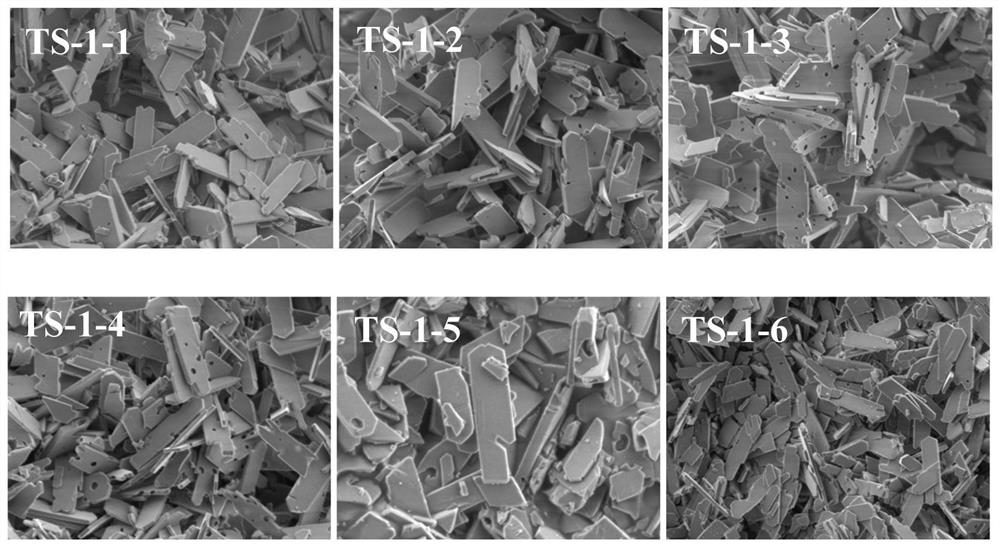

[0055] Example 2: Preparation of Samples TS-1-1 ~ TS-1-6

[0056] First, the urea, inorganic alkali source and organic amine are added to deionized water, stirred, and dissolved, resulting in a mixed solution. The amorphous titanium dioxide / silicon complex prepared by the above solution or the like was extracted, and the solid was obtained for a period of time. The above solid mixture was transferred to the upper plate of the upper portion of the stainless steel high pressure reactor, and the reaction could be added to the bottom of the reaction. The stainless steel reactor was sealed, placed in an oven, and 12 to 40 h at 130 to 180 ° C. After the reaction, the solid product was separated, and the solid product was separated, and the deionized water was washed, dried at 110 ° C in the air atmosphere and 550 ° C for 6 hours, i.e., the sheet TS-1 molecular sieve. The correspondence between the sample number and the preparation conditions are shown in Table 2.

[0057] XRD characte...

Embodiment 3

[0062] Example 3: 1-hexene ring oxidation reaction evaluation

[0063] Experiments use traditional hydrothermal synthesis TS-1 samples, synthetic gel ratio of 1SIO 2 : 0.25TPAOH: 0.02TIO 2 : 35h 2 O. Specific gel formulation step: First, tetrapropyl hydroxide (TPAOH) is added to deionized water at room temperature; a certain amount of orthosilicate and butyl butyl ester is slowly added after sufficient dissolution; After stirring at room temperature for 24 h, the raw material was transferred to a stainless steel synthetic kettle and crystallized at 150 ° C for 24 h. The resulting solid product was centrifuged, then washed, then dried overnight at 110 ° C, and finally the organic template agent was removed at 550 ° C for 6 h, named CONV-TS-1.

[0064] The prepared CONV-TS-1 was evaluated by epoxidation reaction of 1-hexene by a sheet TS-1 molecular sieve prepared in Example 2. The specific steps of the reaction are as follows: Weigh 0.05 g of sample, 1.0 g 1-hexene, 0.375GH 2 O 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com