Preparation method of machinable ceramic surface hydrophobic membrane

A technology of ceramic surface and hydrophobic film, applied in the direction of coating, etc., can solve the problem of poor bonding effect between the film layer and epoxy resin, and achieve good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

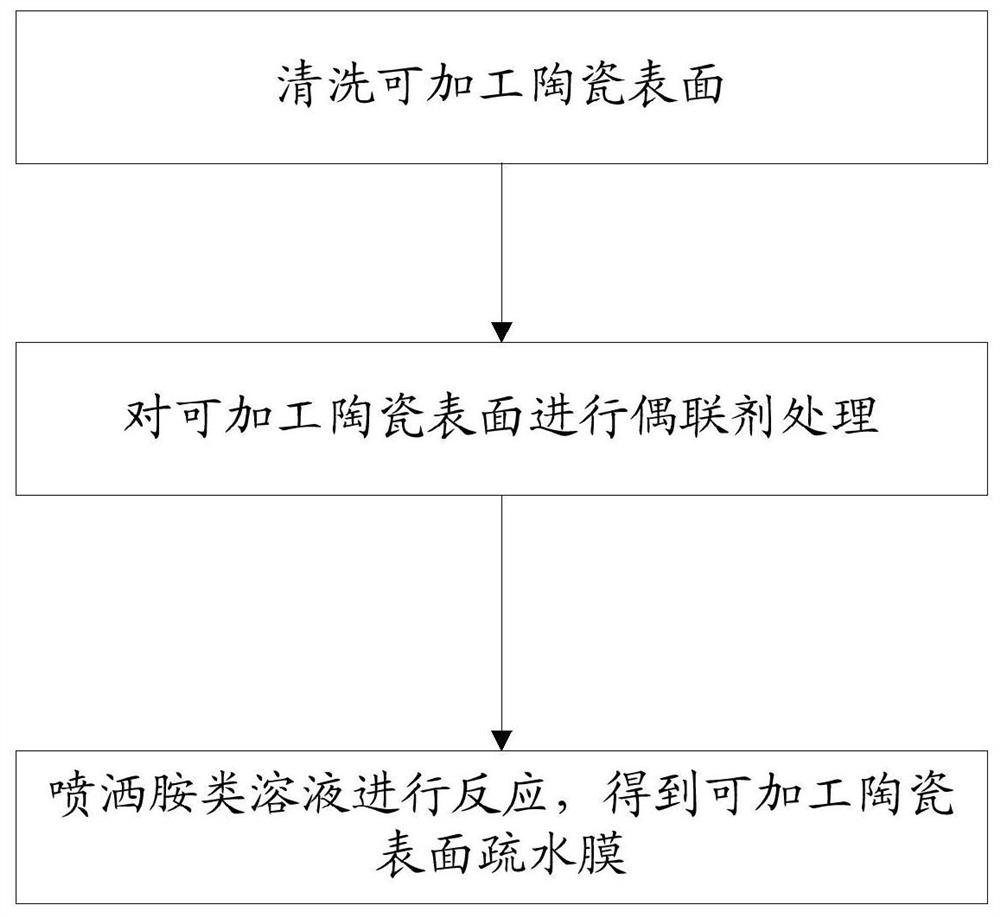

[0025] Such as figure 1 As shown, the invention provides a method for preparing a machinable ceramic surface hydrophobic film, comprising the following steps:

[0026] Step (1), cleaning the machinable ceramic surface.

[0027] The surface cleaning of the machinable ceramics includes: placing the machinable ceramics in a plasma cleaning machine, setting the power to 70-100%, and cleaning time for 2-5 minutes to obtain the machinable ceramics after surface cleaning.

[0028] Step (2), treating the surface of the machinable ceramic with a coupling agent to obtain a machinable ceramic modified by the coupling agent.

[0029] Machinable ceramic surface coupling agent treatments, including:

[0030] Add the coupling agent to an aqueous solution of ethanol for hydrolysis, use acetic acid to adjust the pH value to 3-4, and reflux for 1 hour under stirring conditions; the ratio of coupling agent, water, and ethanol in the ethanol solution of the coupling agent is 1: 1:18 (mass rati...

Embodiment 1

[0040] 1. The embodiment of the present invention provides a machinable ceramic with a hydrophobic film attached to the surface. The specific preparation method is as follows:

[0041] Place the machinable ceramic material in the plasma cleaning machine cabin, set the power of the plasma cleaning machine to 70%, and the cleaning time to 3 minutes, and perform plasma cleaning on the machinable ceramic material.

[0042] Use an analytical balance to weigh 10.0g deionized water, 10.0g organosilane KH-560, and 180.0g absolute ethanol in a flask. After stirring evenly, add an appropriate amount of acetic acid to adjust the pH to 3-4. Under stirring conditions, 80 ℃ reflux reaction for 1h.

[0043] Put the machinable ceramics after plasma cleaning into the organic silane solution to ensure that the surface of the machinable ceramics is completely soaked, keep it for 10 minutes, take it out and put it in a blast drying oven at 100°C for 1 hour, and get the surface coupling agent afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com