Synthesis method of hydroxyl polysiloxane

A technology of hydroxypolysiloxane and synthesis method, which is applied in the field of synthesis of hydroxypolysiloxane, can solve problems such as complex process, many side reactions, and oil floating, and achieve reduction of side reactions, omission of protection steps, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

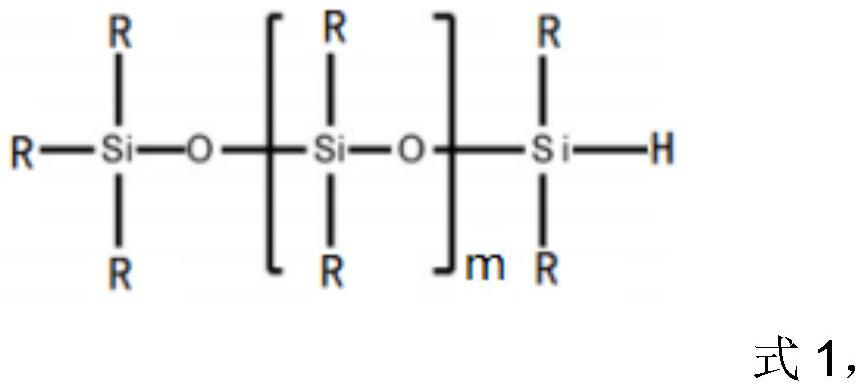

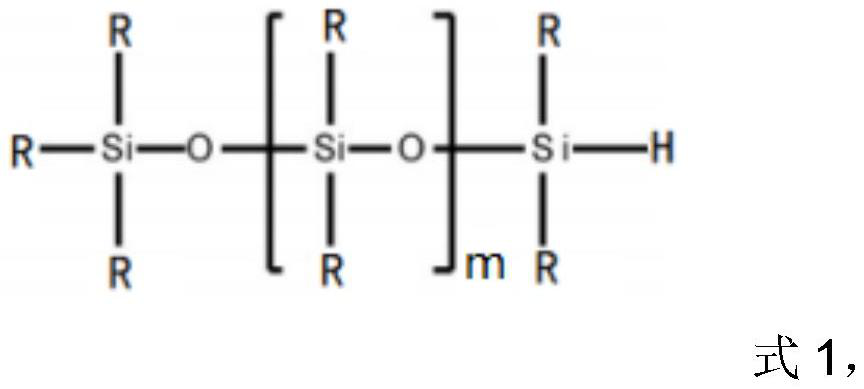

Method used

Image

Examples

Embodiment 1

[0043] Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 5.4g of concentrated sulfuric acid and 600g of toluene and slowly raise the temperature to 75°C, react for 3 hours, add 45g of potassium trimethylsiliconate and 270g of THF and raise the temperature to 80°C for 10 hours , cooled to room temperature, 33g of dimethyl monochlorosilane was added dropwise under ice bath conditions, kept for 20 hours, filtered, and the filtrate was distilled under reduced pressure at 90°C to remove low boilers to obtain hydrogen-terminated silicone oil, and its number average molecular weight was tested It is 1000, and the hydrogen content is 0.10%.

Embodiment 2

[0045] Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 0.9g of trifluoromethanesulfonic acid and 90g of toluene and slowly raise the temperature to 75°C, add 15g of potassium trimethylsiliconate and 45g of THF and raise the temperature to 80°C after 3 hours of reaction React at ℃ for 10 hours, cool to room temperature, add 11g dimethyl monochlorosilane dropwise under ice bath conditions, keep warm for 20 hours, filter, and distill the filtrate under reduced pressure at 90℃ to remove low boilers to obtain hydrogen-terminated silicone oil. The number average molecular weight is 2700, and the hydrogen content is 0.037%.

Embodiment 3

[0047] Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 1.5g of concentrated sulfuric acid and 300g of toluene and slowly raise the temperature to 75°C, react for 3h, then add 25g of potassium trimethylsiliconate and 25gTHF and raise the temperature to 80°C for 10h , cooled to room temperature, 18.5g dimethyl monochlorosilane was added dropwise under ice bath conditions, kept for 20 hours, filtered, and the filtrate was distilled under reduced pressure at 90°C to remove low boilers to obtain hydrogen-terminated silicone oil. The molecular weight is 1700, and the hydrogen content is 0.059%.

[0048] The preparation example of hydroxyl polysiloxane is given below, wherein the viscosity is the dynamic viscosity value at 25°C, the test method refers to GB / T2794-1995, and the test method of hydroxyl content refers to GB / T 12008.3-2009; at the same time, the content of the reaction product is tested Hydrogen content, to investigate the reaction rate of silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com