A kind of production method of environment-friendly latex sponge

The technology of a latex sponge and a production method, which is applied in the latex field, can solve problems such as unenvironmental protection, and achieve the effects of less environmental pollution, favorable for environmental protection and improvement of production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

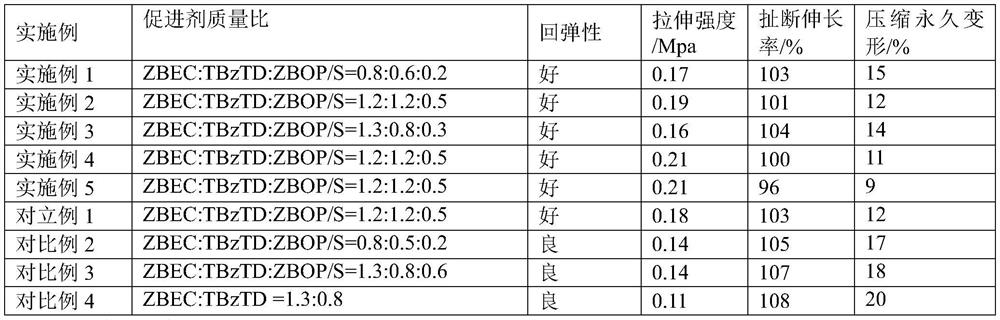

Embodiment 1

[0018] A production method of an environment-friendly latex sponge,

[0019] (1) Vulcanization package dispersion: mix sulfur, accelerator ZBEC, accelerator TBzTD and accelerator ZBOP / S in a mass ratio of 3:0.8:0.6:0.2;

[0020] (2) 100 parts of natural rubber latex, 8 parts of vulcanization package dispersion, 5 parts of potassium oleate, 2 parts of potassium ricinoleate, 3 parts of zinc oxide and 0.5 part of potassium hydroxide were mixed at 30° C. Ageing in water bath for 10 hours, hot air setting for 10 minutes, steam oven curing for 50 minutes, and finally drying to obtain a latex sponge.

Embodiment 2

[0022] A production method of an environment-friendly latex sponge,

[0023] (1) Vulcanization package dispersion: mix sulfur, accelerator ZBEC, accelerator TBzTD and accelerator ZBOP / S in a mass ratio of 3:1.2:1.2:0.5;

[0024] (2) 100 parts of synthetic latex, 10 parts of vulcanization package dispersion, 10 parts of potassium oleate, 5 parts of potassium ricinoleate, 8 parts of zinc oxide and 1 part of potassium hydroxide were mixed at 20° C. Water bath aging for 24 hours. Hot air setting for 20 minutes, steam oven vulcanization for 60 minutes, and finally drying to obtain a latex sponge.

Embodiment 3

[0026] A production method of an environment-friendly latex sponge,

[0027] (1) Vulcanization package dispersion: mix sulfur, accelerator ZBEC, accelerator TBzTD and accelerator ZBOP / S in a mass ratio of 3:1.3:0.8:0.3;

[0028] (2) 100 parts of natural latex and synthetic latex (mixed in a mass ratio of 1:1), 9 parts of vulcanization package dispersion, 7 parts of potassium oleate, 3 parts of potassium ricinoleate, 6 parts of zinc oxide and 0.8 parts of potassium hydroxide, aged in a water bath at 40°C for 6 hours. Hot air setting for 5 minutes, steam oven vulcanization for 40 minutes, and finally drying to obtain a latex sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com