Four-component polyurethane adhesive for capsule material, preparation method and application thereof

A polyurethane adhesive, four-component technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, non-polymer adhesive additives, etc., can solve the problems of low bonding strength, easy to open the layer, not resistant to rubbing, etc. Achieve high bonding strength, solve poor strength, and meet processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides a kind of preparation method of four-component polyurethane adhesive, is characterized in that, comprises the following steps:

[0070] The preparation method of the A component is:

[0071] (1) Put PTMG and PCL into the reaction kettle, stir and heat up to 100-120°C, then vacuumize and keep warm, and when the moisture content is less than 0.02%, cool down to 55±1°C;

[0072] (2) Add catalyst, antioxidant, auxiliary antioxidant and ultraviolet absorber to the reactor, and keep the temperature at 55±1°C during the addition process;

[0073] (3) Add MDI dropwise to the reaction kettle for heating reaction, and lower the temperature to 40-50°C after the reaction;

[0074] (4) Add HMDI into the reactor for heating reaction, and after the reaction, lower the temperature to 40-50°C to obtain component A.

[0075] Specifically, the A component is prepared according to the following process:

[0076] (1) Put an appropriate amount of PTMG a...

Embodiment 1

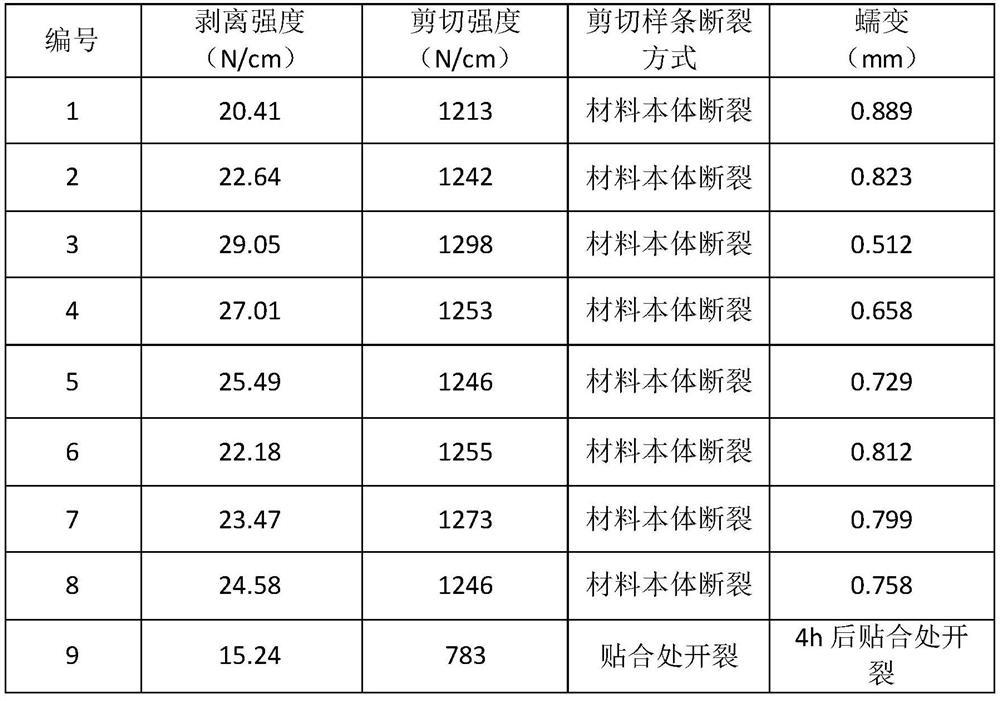

[0122] This example provides a preparation and application method of a four-component polyurethane adhesive for capsule materials, which is prepared by mixing four components A, B, C, and D at a mass ratio of 5:1:1:1.

[0123] A component, B component, C component, and D component are composed of the following raw materials in parts by mass:

[0124] A component

[0125] 20 parts of MDI, 20 parts of HMDI, 30 parts of PTMG (Mn=1000), 30 parts of PCL (Mn=1000), 0.01 part of catalyst dibutyltin dilaurate, 0.1 part of antioxidant 1076, 1680.05 parts of auxiliary antioxidant, 0.3 part of ultraviolet absorber (UV-531);

[0126] B component

[0127] 45 parts of MDI, 55 parts of ether;

[0128] C component

[0129] 25 parts of RFE, 75 parts of ethyl acetate;

[0130] D component

[0131] 5 parts of aluminum hydroxide, 5 parts of stabilizer (vinyltrimethoxysilane and silicon dioxide mixed in a mass ratio of 5:1); 5 parts of white carbon black, 85 parts of acetone;

[0132] The p...

Embodiment 2

[0161] This example provides a preparation and application method of a four-component polyurethane adhesive for capsule materials, which is prepared by mixing four components A, B, C, and D at a mass ratio of 6:1:1:1.

[0162] A component, B component, C component, and D component are composed of the following raw materials in parts by mass:

[0163] A component

[0164] 21 parts of MDI, 21 parts of HMDI, 35 parts of PTMG (Mn=1000), 23 parts of PCL (Mn=1000), 0.01 part of catalyst dibutyltin dilaurate, 0.1 part of antioxidant 1076, 1680.05 parts of auxiliary antioxidant, UV absorber UVP-3210.3 parts;

[0165] B component

[0166] 47 parts of MDI, 53 parts of acetone;

[0167] C component

[0168] 26 parts of RFE, 74 parts of butyl acetate;

[0169] D component

[0170] 5 parts of magnesium hydroxide, 6 parts of stabilizer (vinyltrimethoxysilane and silicon dioxide mixed in a mass ratio of 6:1); 6 parts of white carbon black, 83 parts of acetone;

[0171] The production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com