A kind of hyperbranched organosilicon inhibitor for drilling fluid and preparation method thereof

A silicone and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of weakening effect, achieve the effect of increasing repulsion, delaying hydration time, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

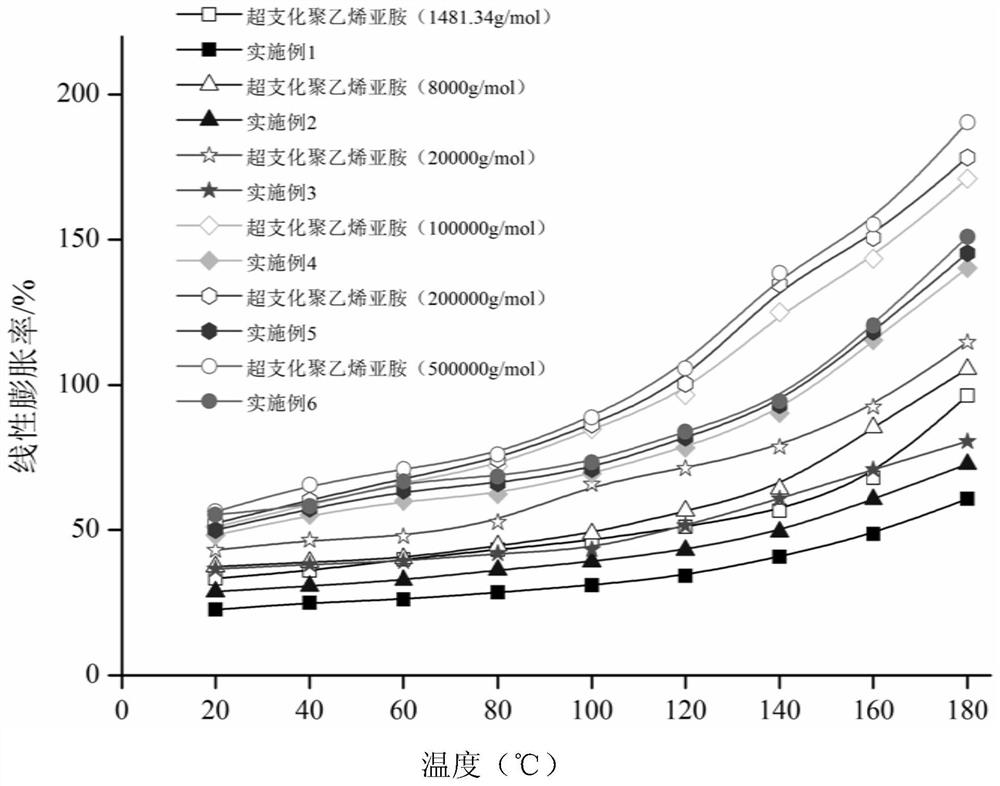

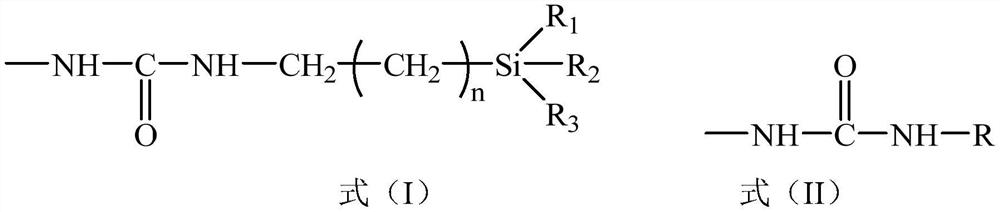

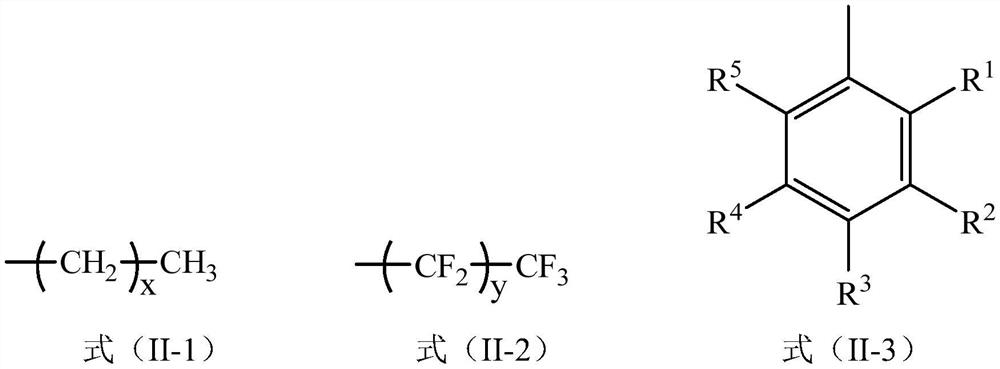

[0085] In a sealed reaction vessel, 40g hyperbranched polyethyleneimine (0.027mol, relative molecular mass is 1481.34g / mol, the number of terminal amine groups is about 14) is dissolved in 500g 1,4-dioxane, controlled Warm to 45°C; then in N 2 Under the protection of -Isocyanatopropyldimethylmethoxysilane in a molar ratio of 1:0.1) and 4.7932 g of dodecyl isocyanate (0.02268 mol, primary amine group to dodecyl isocyanate in hyperbranched polyethyleneimine The molar concentration ratio was 1:0.06), and the reaction was continued for 8 h under continuous stirring to obtain a light yellow viscous liquid. 1,4-dioxane is removed by distillation under reduced pressure, (under normal temperature) the crude product is soaked in (excessive) benzene, filtered, the insolubles are retained, the insolubles are rinsed with benzene, and the benzene is removed by distillation under reduced pressure To a constant weight, the hyperbranched organosilicon inhibitor is obtained.

[0086] The pr...

Embodiment 2

[0090] In a sealed reaction vessel, 160g hyperbranched polyethyleneimine (0.02mol, relative molecular mass is 8000g / mol, the number of terminal amine groups is about 50±5) is dissolved in 1540g 1,4-dioxane, Control the temperature to 48°C; then in N 2 Under the protection of - Isocyanatopropylmethyldimethoxysilane in a molar ratio of 1:0.12) and 26.745 g of hexadecyl isocyanate (0.1 mol, primary amine group to hexadecyl isocyanate in hyperbranched polyethyleneimine) The molar concentration ratio was 1:0.1), and the reaction was continued for 16 h under continuous stirring to obtain a light yellow viscous liquid. 1,4-dioxane is removed by distillation under reduced pressure, (under normal temperature) the crude product is soaked in (excessive) benzene, filtered, the insolubles are retained, the insolubles are rinsed with benzene, and the benzene is removed by distillation under reduced pressure To a constant weight, the hyperbranched organosilicon inhibitor is obtained.

[0...

Embodiment 3

[0095] In a sealed reaction vessel, 150g of hyperbranched polyethyleneimine (0.0075mol, relative molecular mass of 20000g / mol, number of terminal amine groups is about 160±10) was dissolved in 3600g of dimethyl sulfoxide, and the temperature was controlled to 50°C; then at N 2 Under the protection of The molar concentration ratio of propyltrimethoxysilane is 1:0.12) and 15.8667 g perfluorododecyl isocyanate (0.024 mol, primary amine group in hyperbranched polyethyleneimine and mole of perfluorododecyl isocyanate) The concentration ratio was 1:0.02), and the reaction was continued for 22 h under continuous stirring to obtain a light yellow viscous liquid. The dimethyl sulfoxide was removed by distillation under reduced pressure, the crude product was immersed in (excess) benzene (at room temperature), filtered, the insolubles were retained, the insolubles were rinsed with benzene, and the benzene was removed by distillation under reduced pressure to constant weight , that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com