Ultraviolet light-emitting diode with electron deceleration layer structure

A technology of light-emitting diodes and deceleration layers, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of difficulty in significantly improving UV-LED luminous efficiency, limited effect, and high difficulty in epitaxial growth, so as to improve the uniformity of spatial distribution and increase Efficiency, the effect of reducing electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

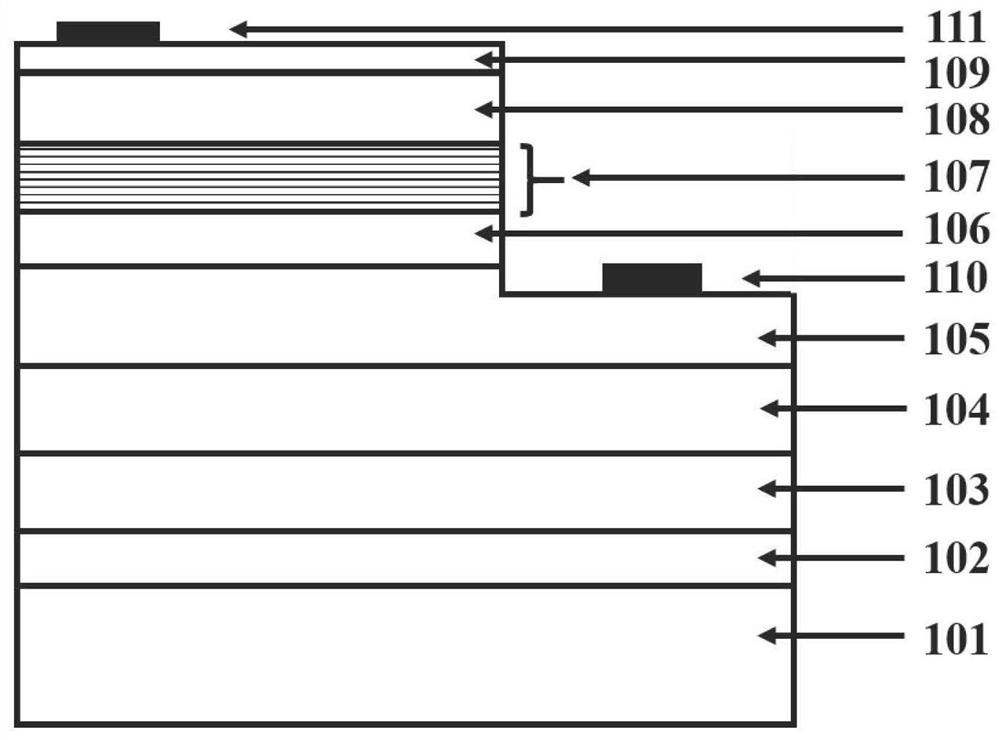

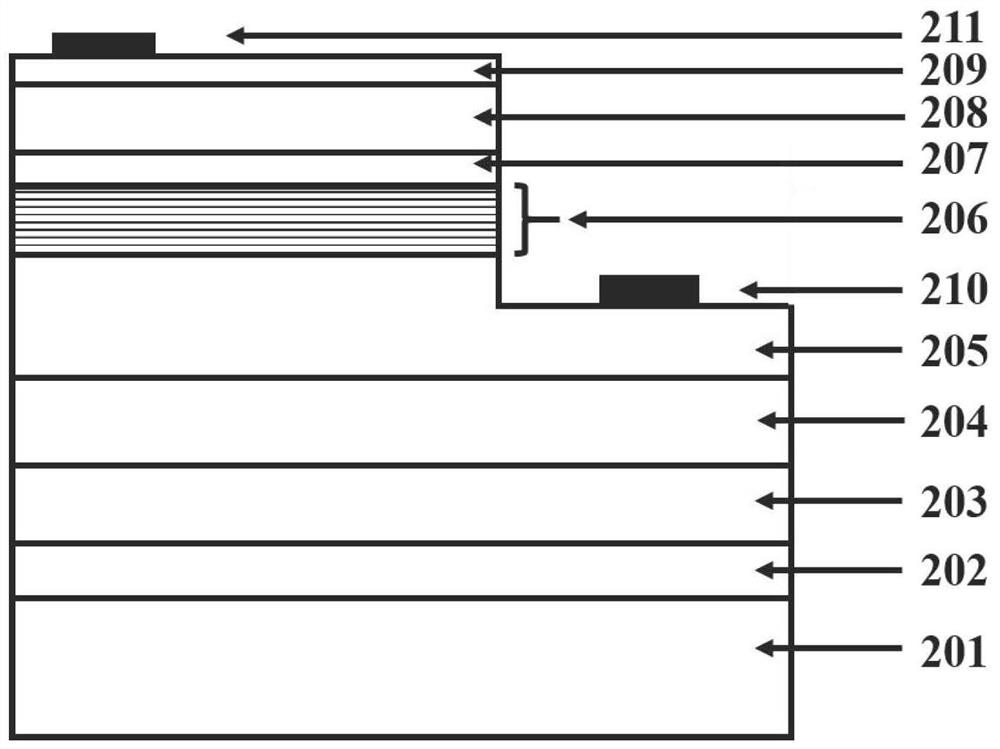

[0014] Such as figure 1 As shown, an ultraviolet light-emitting diode with an electron deceleration layer structure includes a substrate 101, an AlN nucleation layer 102, an AlN buffer layer 103, an undoped AlGaN buffer layer 104, and an n-type AlGaN layer 105 arranged in sequence from bottom to top. , B(Al, Ga)N electron deceleration layer 106, Al x Ga 1-x N / Al y Ga 1-y N multi-quantum well active region 107, p-type AlGaN layer 108 and p-type GaN ohmic contact layer 109, and n-type ohmic electrode 110 set on n-type AlGaN layer 105 and p-type GaN ohmic contact layer 109 set on the p type ohmic electrode 111, where 0<x<y<1.

[0015] The B(Al, Ga)N electron deceleration layer 106 is composed of any one of undoped or n-type doped BAlN, BGaN or BAlGaN layers, and its forbidden band width is always greater than the forbidden band width of the n-type AlGaN layer 105, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com