Preparation method of a molten salt porous silicon-based composite phase change heat storage material

A porous silicon-based, composite phase change technology, used in heat exchange materials, chemical instruments and methods, etc., can solve the complex phase change heat storage material preparation process, the inability to use solar power generation systems, and thermal stability to be improved. problems, to achieve the effects of good chemical stability, large latent heat value, and increased temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The first part of the preparation method of molten salt porous silicon-based composite phase change heat storage material

[0074] 1.1 Raw materials and equipment used

[0075] The main instruments and equipment used in this example are shown in Table 1:

[0076] Table 1

[0077]

[0078] The porous silicon-based carrier material selected in this example is shown in Table 2:

[0079] Table 2

[0080]

[0081] 1.2 Preparation of mixed molten salt

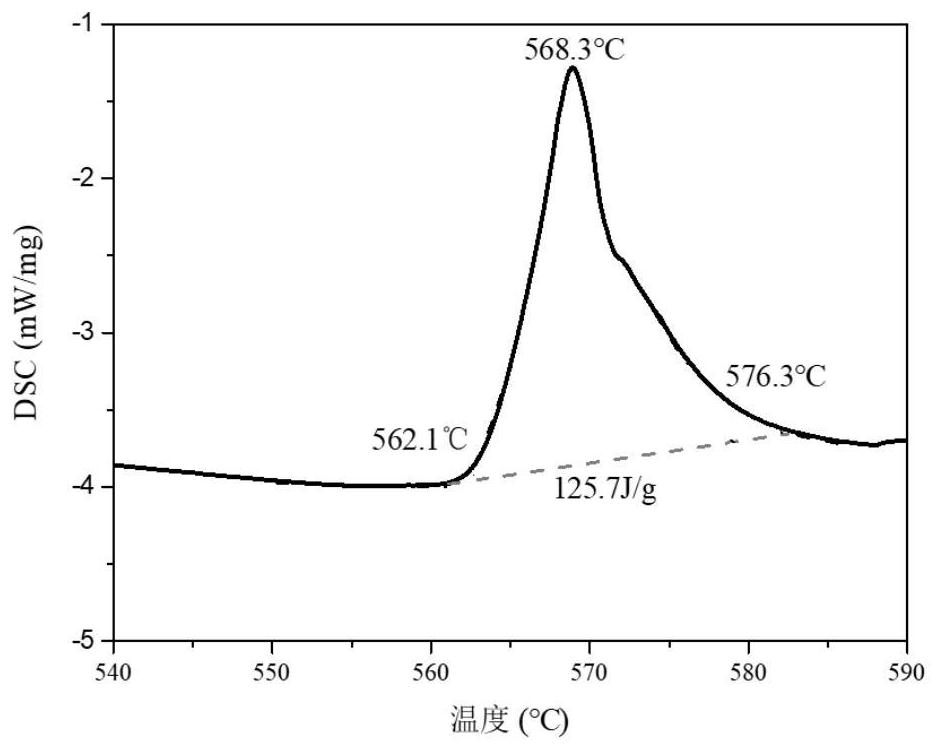

[0082] The mixed molten salt of this embodiment is carbonate-chloride molten salt, and sodium carbonate, potassium carbonate and potassium chloride are respectively weighed according to the mass ratio of 3:5:2, and placed in a drying box with a temperature of 120 ° C respectively. The constant temperature is 96h, so that the adsorbed water in the salt is fully evaporated, and then the three kinds of dried salts are evenly mixed together, placed in a muffle furnace and heated to 500°C at a heating rate of 10°C / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com