Infrared focal plane detector and manufacturing method thereof

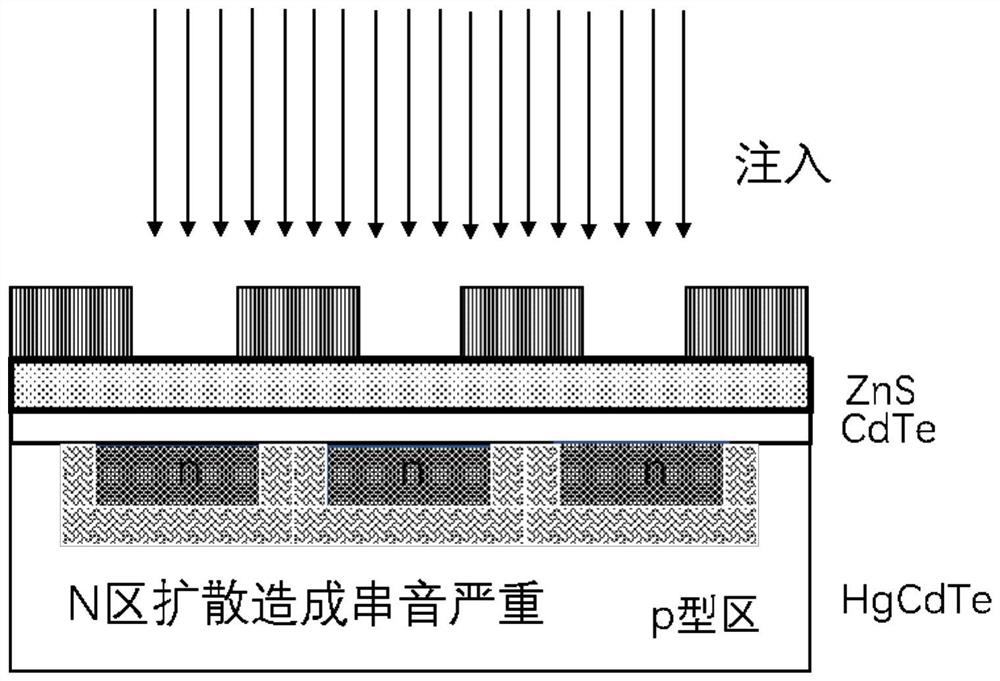

A technology of an infrared focal plane and a manufacturing method, applied in the field of infrared focal plane detectors and their manufacturing, can solve the problems of signal attenuation, performance degradation of infrared detectors, crosstalk of photosensitive elements, etc., so as to reduce size, improve detection accuracy, and avoid crosstalk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

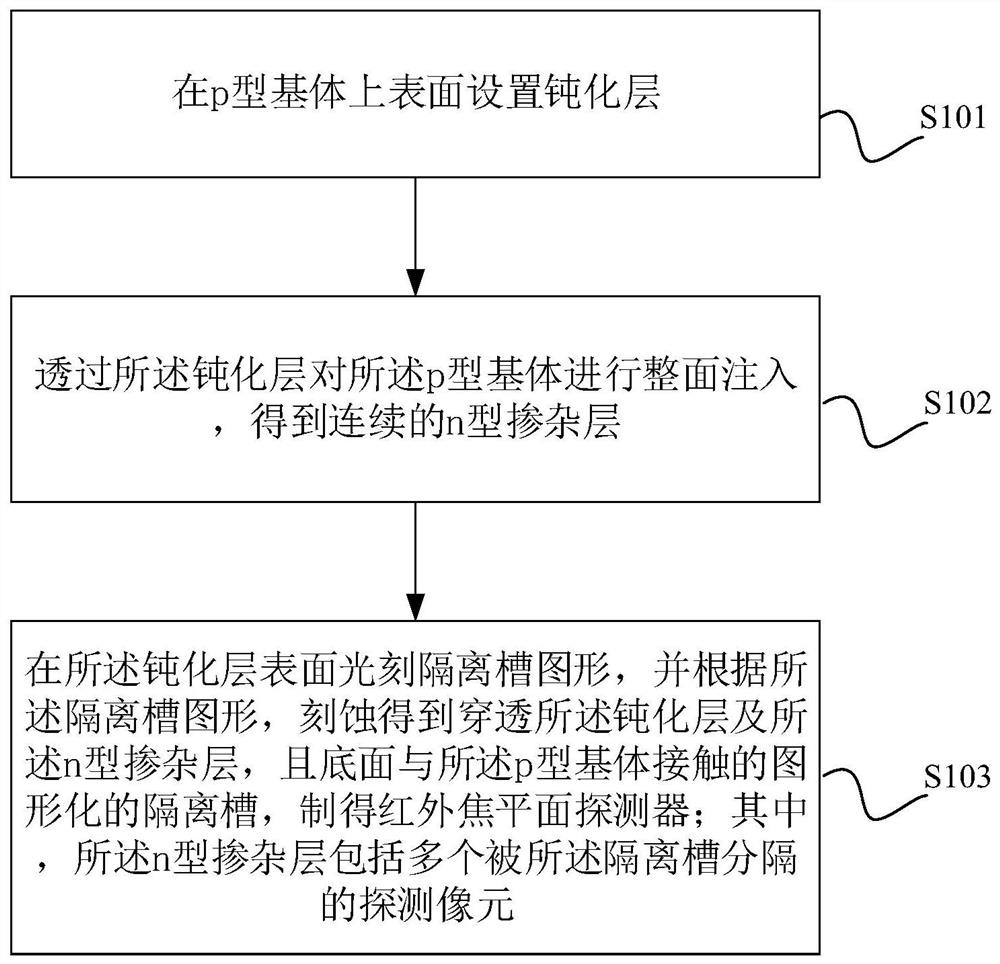

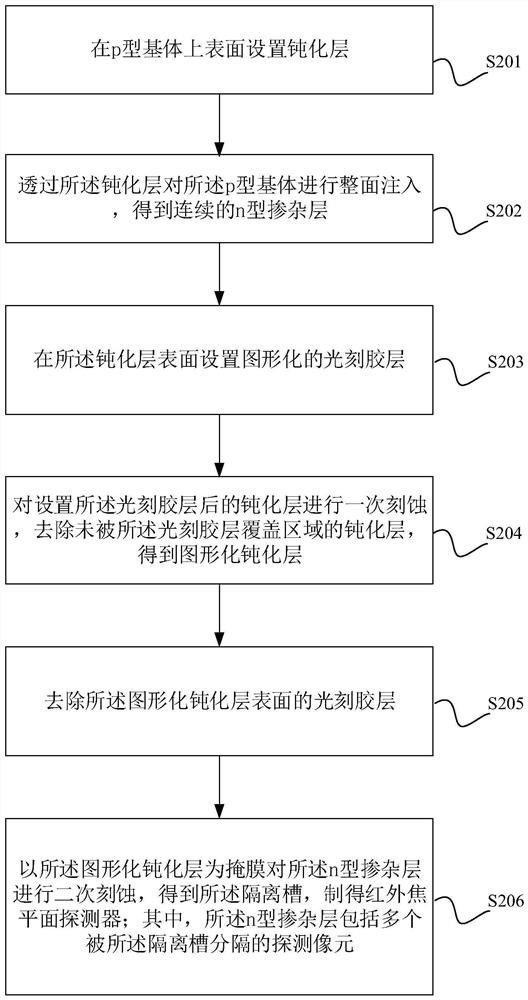

[0038] The core of the present invention is to provide a method for manufacturing an infrared focal plane detector, and a schematic flow chart of a specific implementation thereof is as follows: figure 2 As shown, it is called the first specific implementation mode, including:

[0039] S101: setting a passivation layer on the upper surface of the p-type substrate.

[0040] As a preferred embodiment, the p-type matrix is a mercury cadmium telluride matrix, which is an important material for preparing infrared detectors. Due to its adjustable band gap, the detection spectrum ranges from short-wave bands to Extending to the very long wave band, it has the advantages of high photoelectric detection efficiency; correspondingly, the passivation layer is a zinc sulfide passivation layer.

[0041] Wherein, the zinc sulfide passivation layer has a thickness ranging from 0.2 microns to 0.5 microns, inclusive, such as any one of 0.20 microns, 0.30 microns or 0.50 microns.

[0042] S...

specific Embodiment approach 4

[0076] The present invention also provides a kind of infrared focal plane detector at the same time, the structure schematic diagram of a kind of specific embodiment of it is as follows Figure 6 As shown, it is called the fourth specific embodiment, which includes a p-type base 100, an n-type doped layer 200 and a passivation layer 400 from bottom to top;

[0077] The passivation layer 400 includes a patterned isolation groove 410;

[0078] The isolation groove 410 penetrates the passivation layer 400 and the n-type doped layer 200 , and its bottom surface is in contact with the p-type base 100 ;

[0079] The n-type doped layer 200 includes a plurality of detection pixels separated by the isolation groove 410 .

[0080] In addition, a passivation transition layer 300 is further included between the n-type doped layer 200 and the passivation layer 400 .

[0081] Taking the infrared focal plane detector of mercury cadmium telluride material described above as an example, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com