Organic electrolyte with wide working temperature zone, and sodium ion battery

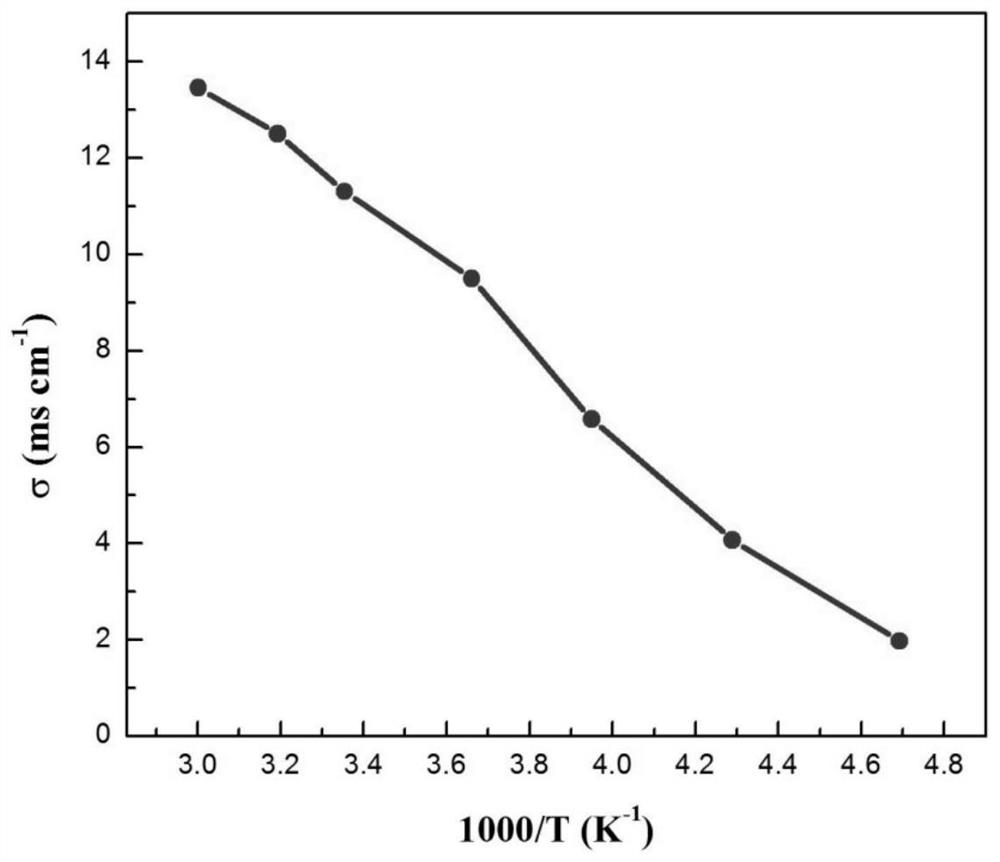

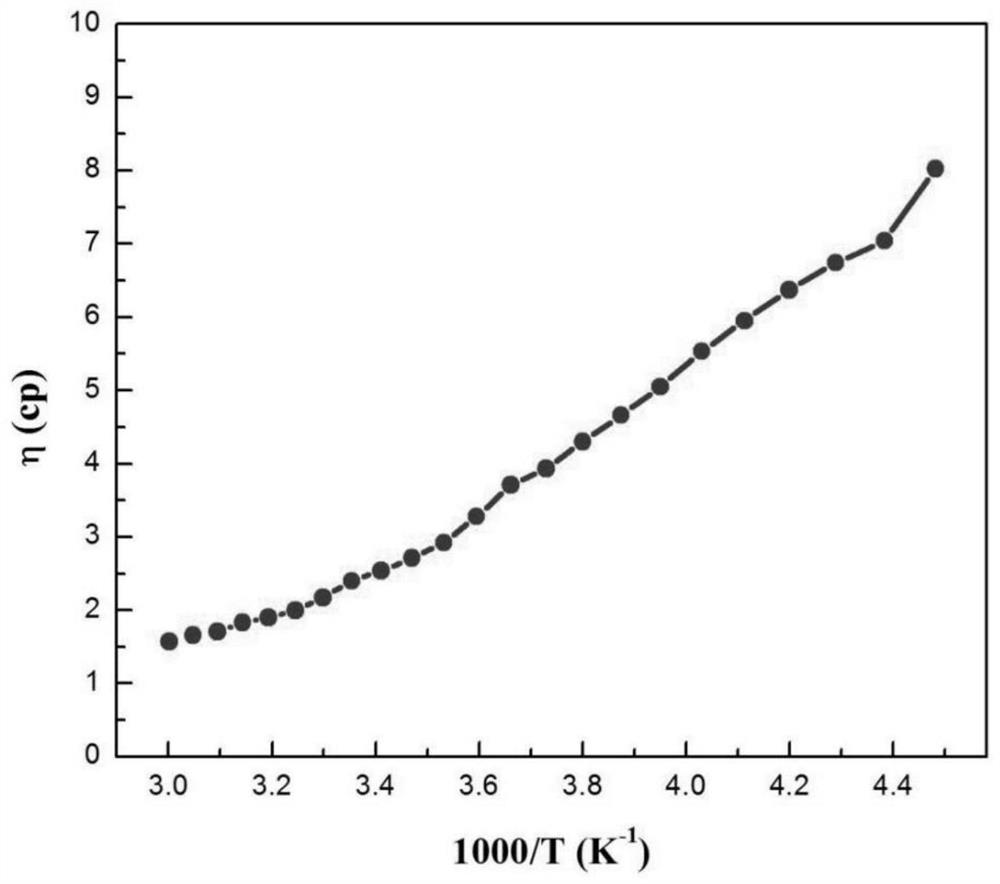

An organic electrolyte and sodium-ion battery technology, applied in the field of sodium-ion batteries, can solve the problems of unsuitable working temperature range and wide range of sodium-ion battery electrolyte, and achieve improved cycle life and Coulombic efficiency, high ionic conductivity, The effect of viscosity and melting point reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the sodium ion battery comprises: 1) preparing a bare cell; 2) configuring an electrolyte; 3) assembling the battery. This preparation method is a common method in the industry, and will not be described in detail here. The following specific examples will be described by selecting different electrolyte sodium salts, organic solvents, and positive and negative electrodes.

[0046] The sodium ion battery provided by the present invention includes the above-mentioned organic electrolyte solution with a wide working temperature range, and the organic electrolyte solution has a higher matching property when applied to a sodium ion battery. The viscosity of the liquid is kept in a more reasonable range, thereby improving the conductivity of the organic electrolyte, and at the same time, the boiling point is higher and the melting point is lower, so the working temperature range is wider and the stability is higher. Therefore, a wide working temperatu...

Embodiment 1

[0049] The present embodiment provides a kind of sodium ion battery, and concrete steps are as follows:

[0050] 1) Preparation of bare cells: stack sodium sheets, diaphragm GF-D and sodium sheets in sequence in the electrode shell under high-purity argon gas to form bare cells;

[0051] 2) Electrolyte configuration: configure the sodium ion battery electrolyte in a glove box filled with argon, wherein the electrolyte salt is sodium hexafluorophosphate, the concentration is 1M; the organic solvent is diethylene glycol dimethyl ether and 1,3- Dioxolane (volume ratio 1:1), stirring and mixing obtains the organic electrolyte of embodiment 1;

[0052] 3) Assemble the metal sodium symmetrical battery: under high-purity argon gas, drop the organic electrolyte obtained in step 2) to the bare cell, and after the cell is fully infiltrated, completely seal the battery case to obtain a sodium ion battery;

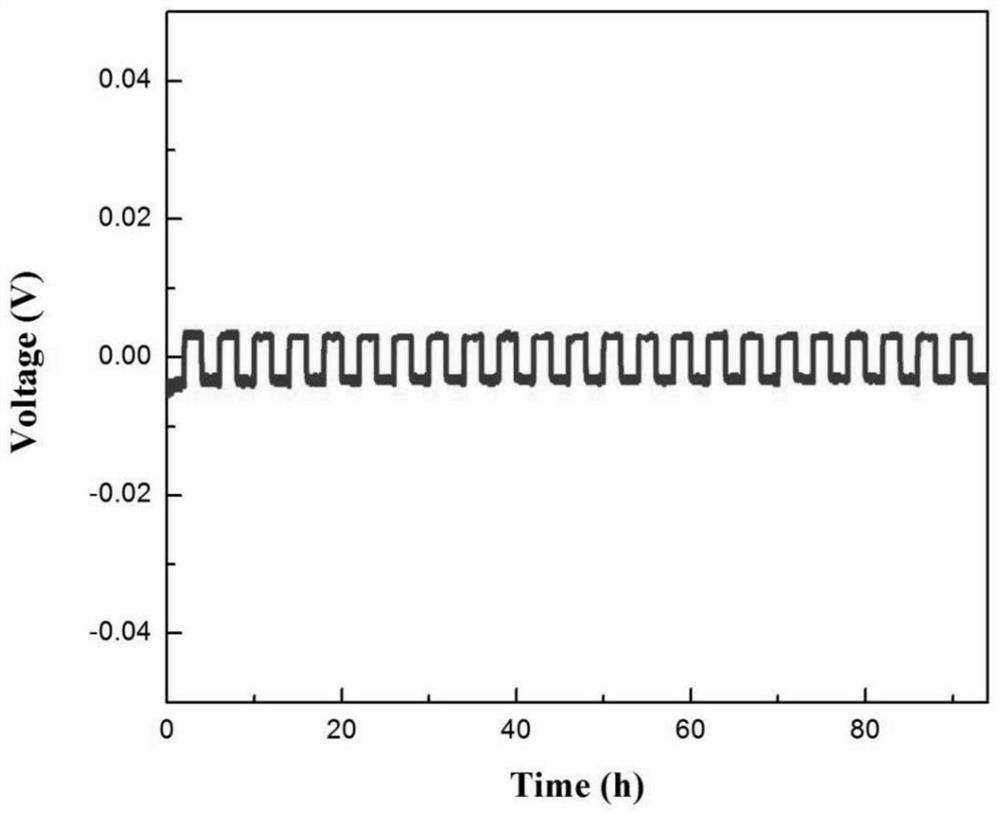

[0053] 4) Metal sodium symmetric battery test: The above-assembled metal sodium ...

Embodiment 2

[0058] The present embodiment provides a kind of sodium ion battery, and concrete steps are as follows:

[0059] 1) Preparation of bare cells: Weigh hard carbon, acetylene black and PVDF according to the mass ratio of 85:5:10, add N-methylpyrrolidone (NMP) to grind and mix, coat on aluminum foil, dry in high-purity Lay the hard carbon electrode, the diaphragm GF-D and the sodium sheet in the electrode shell at one time to form a bare cell under argon gas;

[0060] 2) Electrolyte configuration: configure the sodium ion battery electrolyte in a glove box filled with argon, wherein the electrolyte salt is sodium hexafluorophosphate, the concentration is 1M; the organic solvent is diethylene glycol dimethyl ether and 1,3- Dioxolane (volume ratio 1:1), stirring and mixing to obtain an organic electrolyte;

[0061] 3) Assembling the hard carbon battery: under high-purity argon gas, drop the organic electrolyte obtained in step 2) to the bare battery cell, and after the battery cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com