Pregnant and lying-in woman formula milk powder for relieving lactose intolerance

A technology for lactose intolerance and formula milk powder, which is applied in the direction of dairy products, milk preparations, bacteria used in food preparation, etc., to achieve high safety, high preference, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

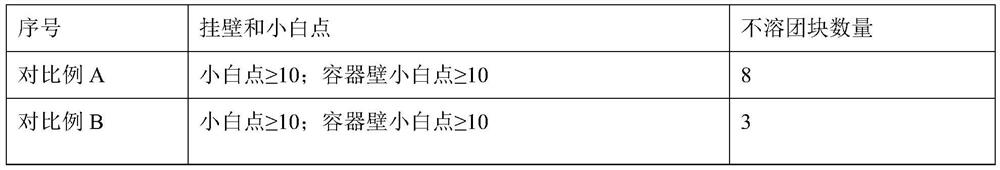

Examples

preparation example Construction

[0062] The preparation method of lactose-free milk powder comprises the following steps:

[0063] Step 1: The raw milk is subjected to ultrafiltration (UF). Obtain UF retentate containing whey protein, a small amount of lactose, and UF permeate containing lactose, inorganic salts, etc.;

[0064] Step 2: Perform polysulfone composite membrane nanofiltration (PSFNF) on the UF permeate. Obtain the PSFNF retentate containing inorganic salts, lactose, etc., and the PSFNF permeate containing a small amount of lactose and a small amount of inorganic salts;

[0065] Step 3: Perform aromatic polyamide composite membrane nanofiltration (PANF) on the PSFNF permeate. A lactose-containing PANF retentate and a lactose-free PANF permeate were obtained.

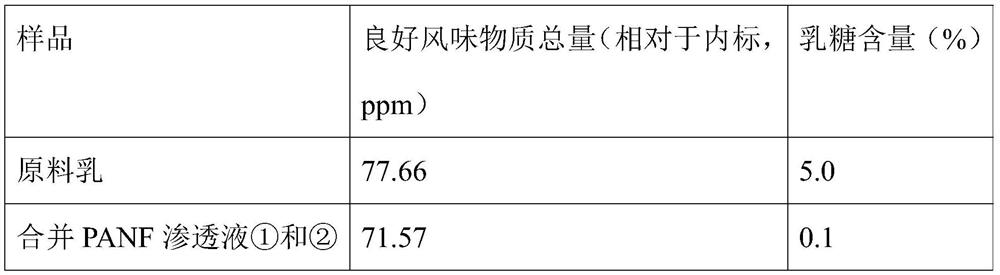

[0066] Step 4: The obtained UF retentate was subjected to steps 2 and 3 for 1-3 times to obtain lactose-free PANF permeate. Combine the PANF permeate from step 3 and step 4 to obtain the combined PANF permeate. Samples were taken to det...

Embodiment 1

[0078] Embodiment 1: Preparation of lactose-free whole milk powder

[0079] Through different pore sizes and different types of membranes, the lactose component in the whole milk is removed by graded filtration. The specific graded filtration operation is as follows:

[0080] (1) Pass pasteurized whole milk (fat content 3.2%) through a tubular ultrafiltration membrane (the material of the tubular ultrafiltration membrane separation layer is polyethersulfone PES, the molecular weight cut-off is 10KDa, and the diameter of the membrane tube is 12mm. The effective membrane area is 2.27㎡). The ultrafiltration operating conditions are: 0.6MPa, feed liquid temperature 35°C, concentration factor 2. Obtain UF permeate and UF retentate, the content of lactose in UF retentate is 3.5%;

[0081] (2) Pass the UF permeate through polysulfone composite membrane nanofiltration (PSFNF), nanofiltration membrane model NF270-400 / 34i (Dow FILMTEC), (nanofiltration membrane separation layer materi...

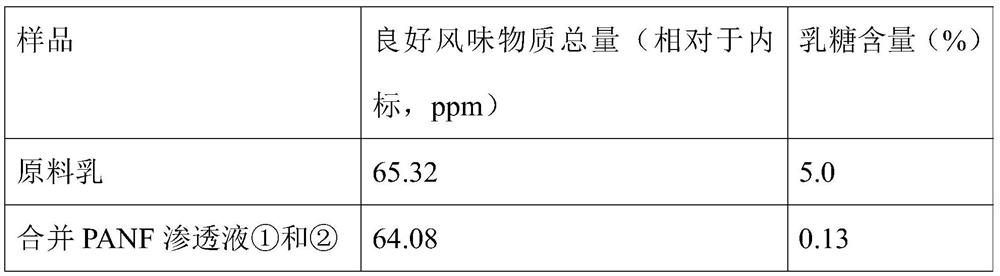

Embodiment 2

[0090] Embodiment 2: Preparation of lactose-free skimmed milk powder

[0091] Through different pore sizes and different types of membranes, the lactose component in the whole milk is removed by graded filtration. The specific graded filtration operation is as follows:

[0092] (1) Pass pasteurized skim milk (fat content 0.4%) through a hollow fiber ultrafiltration membrane (the material of the hollow fiber ultrafiltration membrane separation layer is polyvinylidene fluoride PVDF, the nominal filter pore size is 0.08 μm, and the effective membrane area is 10.0㎡), ultrafiltration operating conditions: 0.3MPa, feed liquid temperature 35°C, concentration factor 2. Obtain UF permeate and UF retentate, the content of lactose in UF retentate is 4.4%;

[0093] (2) Pass the UF permeate through polysulfone composite membrane nanofiltration (PSFNF), nanofiltration membrane model HYDRACoRe50-LD-4040 (Hydranautics, the United States), (nanofiltration membrane material sulfonated polyethers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com