Preparation method and application of carbon molecular sieve for separating olefin and alkane

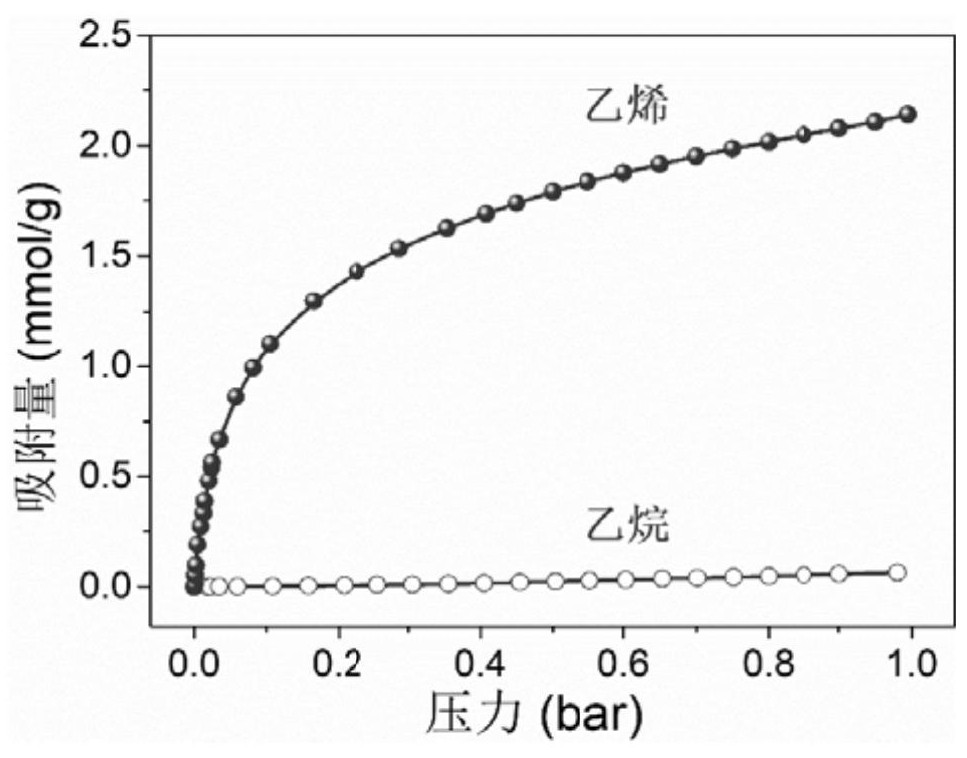

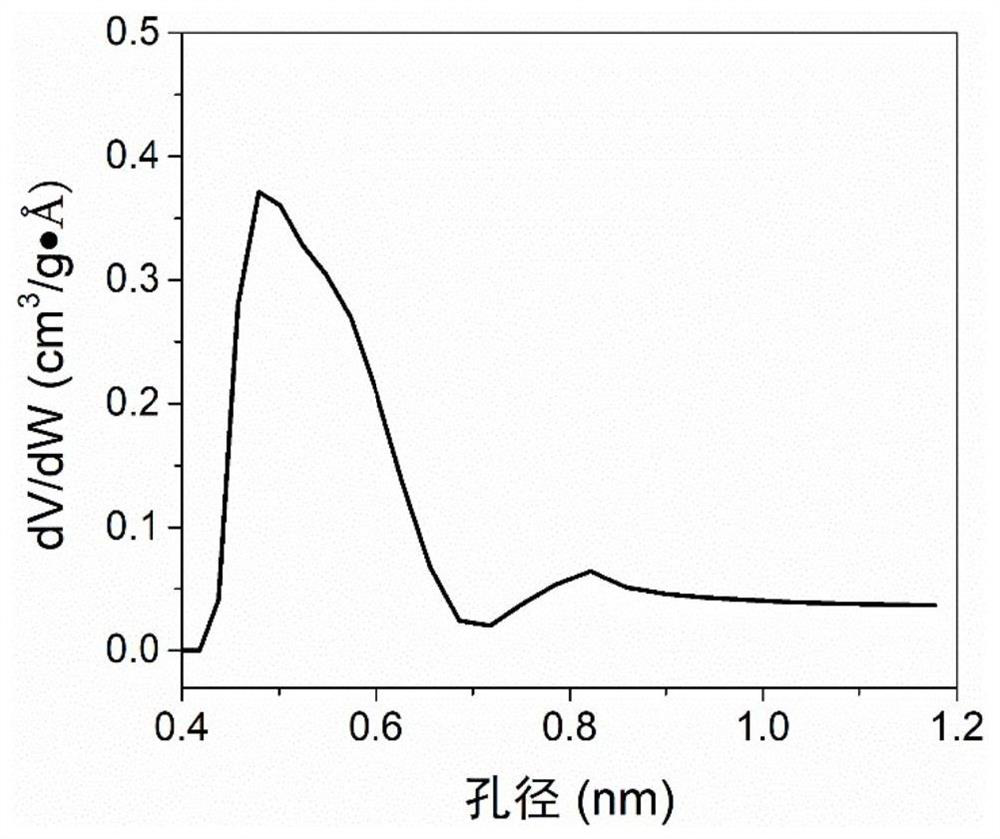

A carbon molecular sieve and olefin alkane technology, which is applied in the fields of carbon preparation/purification, adsorption purification/separation, chemical instruments and methods, etc., can solve the problems of wide pore size distribution, high defect content, difficult fine adjustment, etc., and achieves simple process operation. , to avoid the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

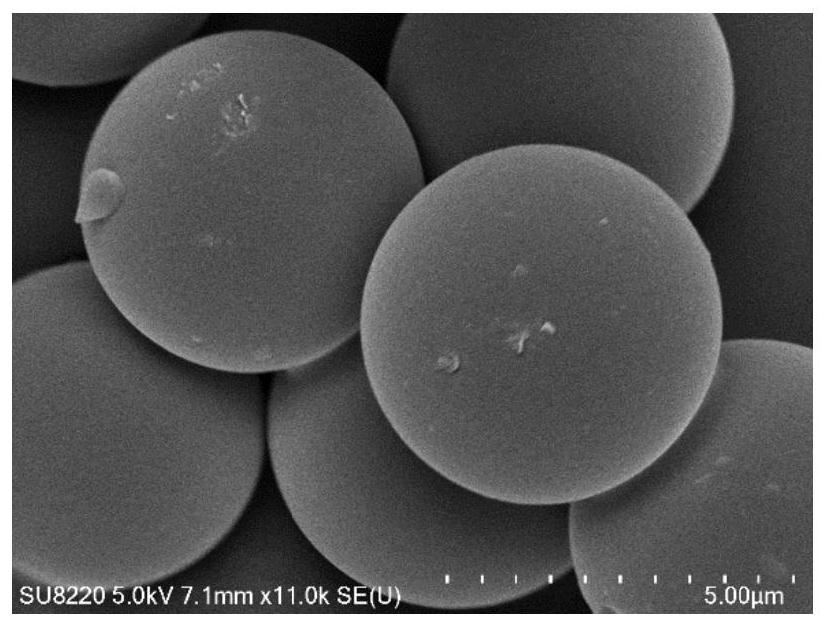

[0049] (1) Mix 3g of wheat starch and 30mL of distilled water to form a mixture with a concentration of 0.03g / mL, and stir for 30min to disperse evenly. Then the mixture was transferred to the reactor for hydrothermal polymerization carbonization, the temperature was constant at 200°C, the pressure was 1.55MPa, and the reaction was carried out for 10h to obtain I D / I G Carbon microspheres with a value of 0.94.

[0050] (2) Fully wash the carbon microspheres with deionized water. After the solid is dried, it is placed in a high-temperature tube furnace, heated to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and then carbonized and pyrolyzed for 1 hour. The product obtained after cooling is 1 # No. carbon molecular sieve material.

Embodiment 2

[0052] (1) Mix 6 g of cornstarch and 6 mL of distilled water to prepare a starch aqueous solution with a concentration of 1 g / mL, and stir for 30 min at room temperature to disperse evenly. Then the mixture was transferred to the reactor for hydrothermal polymerization, the temperature was constant at 190°C, the pressure was 1.24MPa, and the reaction was carried out for 14h to obtain I D / I G Carbon microspheres with a value of 0.87.

[0053] (2) Fully wash the carbon microspheres with deionized water. After the solid is dried, put it in a high-temperature tube furnace, heat it to 1000°C at a heating rate of 5°C / min under a nitrogen atmosphere, and then carbonize and pyrolyze it for 2 hours. The product obtained after cooling is 2 # No. carbon molecular sieve material.

Embodiment 3

[0055] (1) Mix 6g of cornstarch and 6mL of distilled water to form a mixture with a concentration of 1g / mL, and stir for 30min at room temperature to disperse evenly. Then the mixture was transferred to the reactor for hydrothermal polymerization, the temperature was constant at 190°C, the pressure was 1.24MPa, and the reaction was carried out for 14h to obtain I D / I G Carbon microspheres with a value of 0.87.

[0056] (2) Fully wash the carbon microspheres with deionized water. After the solid is dried, put it in a high-temperature tube furnace, heat it to 800°C at a rate of 5°C / min under a nitrogen atmosphere, and then carbonize and pyrolyze it for 2 hours. The product obtained after cooling is 3 # No. carbon molecular sieve material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com