Wet-process refined selenium refining process taking lead-zinc smelting acid mud as raw material

An acid sludge, lead and zinc technology, applied in the field of mineral smelting, can solve the problems of large amount of flue gas, affecting the popularization and application of pyrotechnic selenium extraction process, high energy consumption, reducing dust and flue gas, reducing workload and pollutants Emissions, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

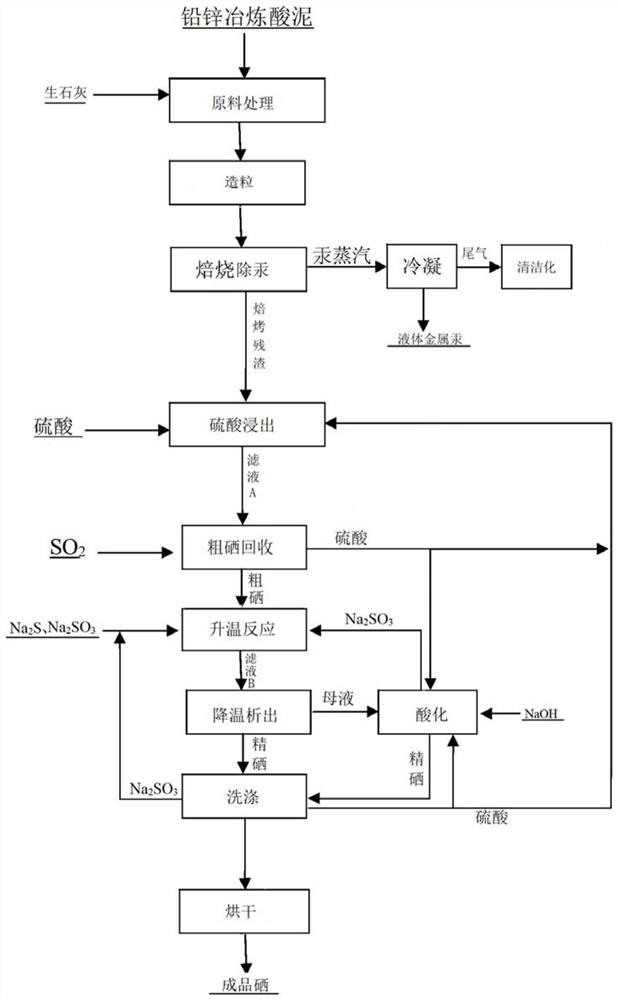

[0028] The invention provides a process for refining selenium by wet process with lead-zinc smelting acid mud as raw material, and its process flow is as follows figure 1 As shown, the following steps are included: (1), raw material processing: the lead-zinc smelting acid mud and quicklime are proportioned by mass, and the mass ratio range is 1:7, and 100g of acid mud and 700g of quicklime are weighed and uniformly mixed in a mixer Mixing, the main components in the acid mud are calculated as (%) by mass percentage: Pb36.31, Se35.24, Hg11.24, Fe10.37, Zn6;

[0029] (2) Granulation: Put the mixed material into a granulator to make small balls with a diameter of 7mm; through granulation, the dust generated during the baking process can be reduced, thereby reducing the generation of mercury soot, improving the production rate of live mercury and Smelting mercury direct recovery rate;

[0030] (3) Mercury removal by roasting: the granulated material is roasted in a rotary kiln un...

Embodiment 2

[0051] The present invention provides a process for refining selenium by wet process using lead-zinc smelting acid mud as a raw material. The reaction equation involved in this embodiment is consistent with that in Embodiment 1, and will not be repeated here. Concretely comprise the following steps: (1), raw material processing: with lead-zinc smelting acid mud and quicklime according to mass ratio, the mass ratio range is 1:7, take by weighing 100g acid mud and 700g quicklime and mix uniformly in the mixer, The main components in the acid mud are calculated as (%) by mass percentage: Pb36.31, Se35.24, Hg11.24, Fe10.37, Zn6;

[0052] (2) Granulation: Put the mixed material into a granulator to make small balls with a diameter of 7mm; through granulation, the dust generated during the baking process can be reduced, thereby reducing the generation of mercury soot, improving the production rate of live mercury and Smelting mercury direct recovery rate;

[0053] (3) Mercury remov...

Embodiment 3

[0064] The present invention provides a process for refining selenium by wet process using lead-zinc smelting acid mud as a raw material. The reaction equation involved in this embodiment is consistent with that in Embodiment 1, and will not be repeated here. Concretely comprise the following steps: (1), raw material processing: with lead-zinc smelting acid mud and quicklime according to mass ratio, the mass ratio range is 1:7, take by weighing 100g acid mud and 700g quicklime and mix uniformly in the mixer, The main components in the acid mud are (%) by mass percentage: Pb36.31, Se35.24, Hg11.24, Fe10.37, Zn6.

[0065] (2) Granulation: Put the mixed material into a granulator to make small balls with a diameter of 7mm; through granulation, the dust generated during the baking process can be reduced, thereby reducing the generation of mercury soot, improving the production rate of live mercury and Smelting mercury direct recovery rate.

[0066] (3) Mercury removal by roasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com