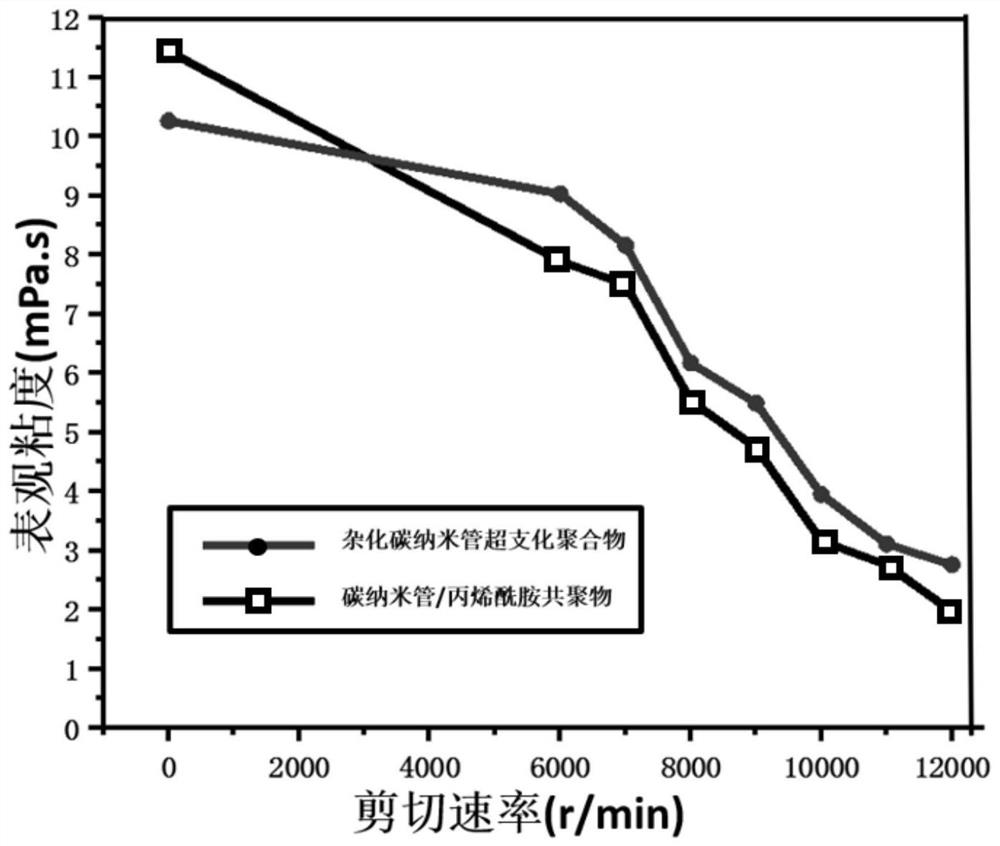

Hyperbranched polymer based on carbon nanotube and preparation method thereof

A technology of hyperbranched polymers and carbon nanotubes, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as poor effects, and achieve broad application prospects, wide application range, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

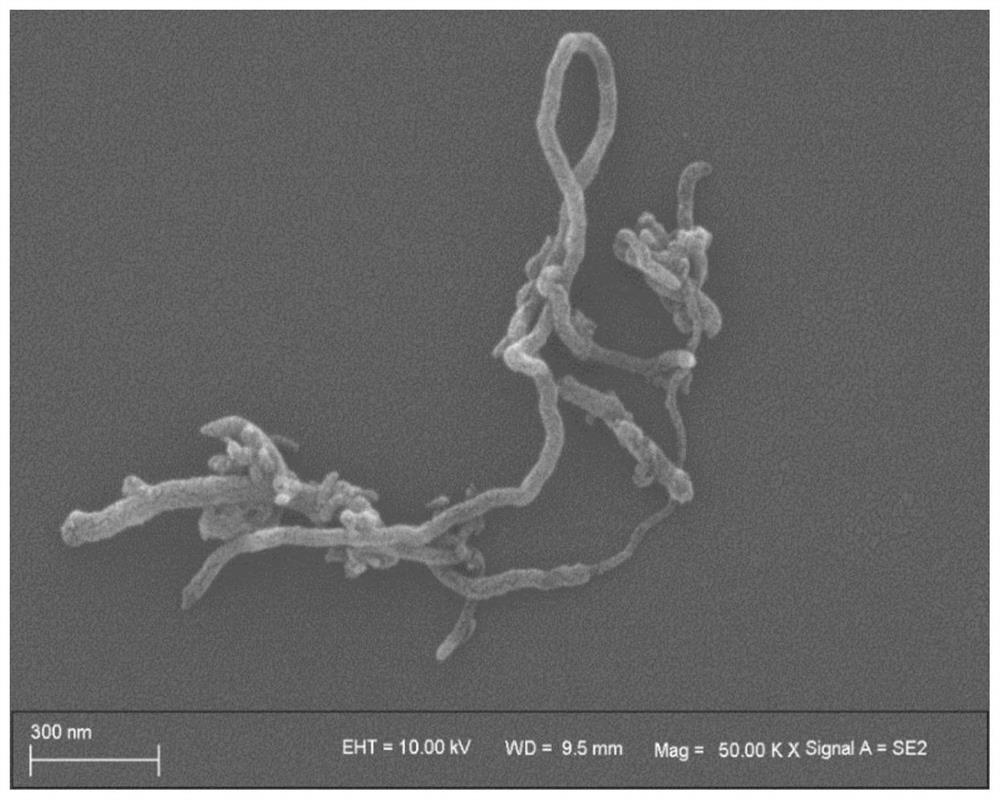

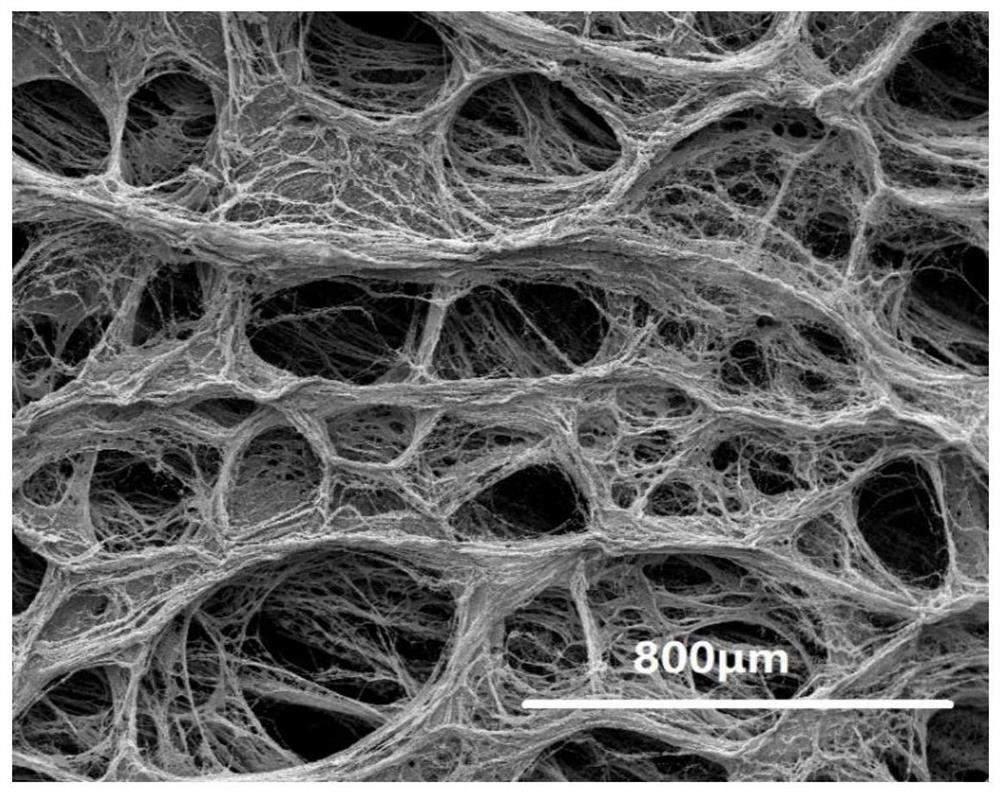

[0031] Add 8g of carbon nanotubes to a 500mL three-necked flask, then add 80g of concentrated nitric acid, stir in a 45°C water bath for 12 hours, filter and wash with suction to obtain carboxylated carbon nanotubes; add 7g of carboxylated carbon nanotubes to a 500mL three-necked flask tube, add 100g of hydrogen peroxide, continue to oxidize in a water bath at 45°C for 12 hours, filter with suction, wash, and dry to obtain hydroxylated carbon nanotubes;

[0032] Add 60g of diformamide and 6g of hydroxylated carbon nanotubes into a 500mL three-necked bottle, then add 60g of aminopropyltrimethoxysilane, and stir in a water bath at 45°C for 12 hours to ensure the hydroxylated carbon nanotubes and silane coupling agent. Fully react, after the reaction is finished, it is filtered, washed and dried;

[0033] In a water bath at 35°C, disperse 5g of carbon nanotubes modified by a silane coupling agent into a three-necked bottle containing 60g of diformamide, add 40g of methyl acrylate...

Embodiment 2

[0038] Add 8g of carbon nanotubes to a 500mL three-necked flask, then add 80g of concentrated nitric acid, stir in a 45°C water bath for 12 hours, filter and wash with suction to obtain carboxylated carbon nanotubes; add 7g of carboxylated carbon nanotubes to a 500mL three-necked flask tube, add 100g of hydrogen peroxide, continue to oxidize in a water bath at 45-50°C for 12 hours, suction filter, wash and dry to obtain hydroxylated carbon nanotubes;

[0039] Add 60g of diformamide and 6g of hydroxylated carbon nanotubes into a 500mL three-necked flask, then add 50g of aminopropyltriethoxysilane and 20g of aminopropyltrimethoxysilane, and stir in a water bath at 50°C for 12h to ensure that the hydroxylated carbon nanotubes Full reaction of carbon nanotubes and silane coupling agent;

[0040] At 40°C in a water bath, disperse 5g of carbon nanotubes modified by a silane coupling agent into a three-necked bottle containing 60g of diformamide, add 40g of methyl acrylate dropwise, ...

Embodiment 3

[0045] Add 8g of carbon nanotubes to a 500mL three-necked flask, then add 80g of concentrated nitric acid, stir in a water bath at 50°C for 12 hours, filter and wash with suction to obtain carboxylated carbon nanotubes; add 7g of carboxylated carbon nanotubes to a 500mL three-necked flask tube, add 100g of hydrogen peroxide, continue to oxidize in a water bath at 50°C for 12h, suction filter, wash, and dry to obtain hydroxylated carbon nanotubes;

[0046] Add 60g of diformamide and 6g of hydroxylated carbon nanotubes into a 500mL three-neck flask, then add 70g of aminopropyltriethoxysilane, and stir in a water bath at 50°C for 12h to ensure that the hydroxylated carbon nanotubes and silane coupling agent an adequate response;

[0047] In a water bath at 35°C, disperse 5g of carbon nanotubes modified by a silane coupling agent into a three-necked bottle containing 60g of diformamide, add 40g of methyl acrylate dropwise, stir in a sealed environment, and conduct Michael Additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com