DUT-67 and batch preparation method and application thereof

A DUT-67, batch technology, applied in chemical instruments and methods, other chemical processes, sustainable manufacturing/processing, etc., can solve problems such as inability to carry out industrial production and application, high energy required for reaction, and long preparation time, etc. Achieve the effects of increasing the concentration of activation sites, increasing the probability of nucleation, and reducing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

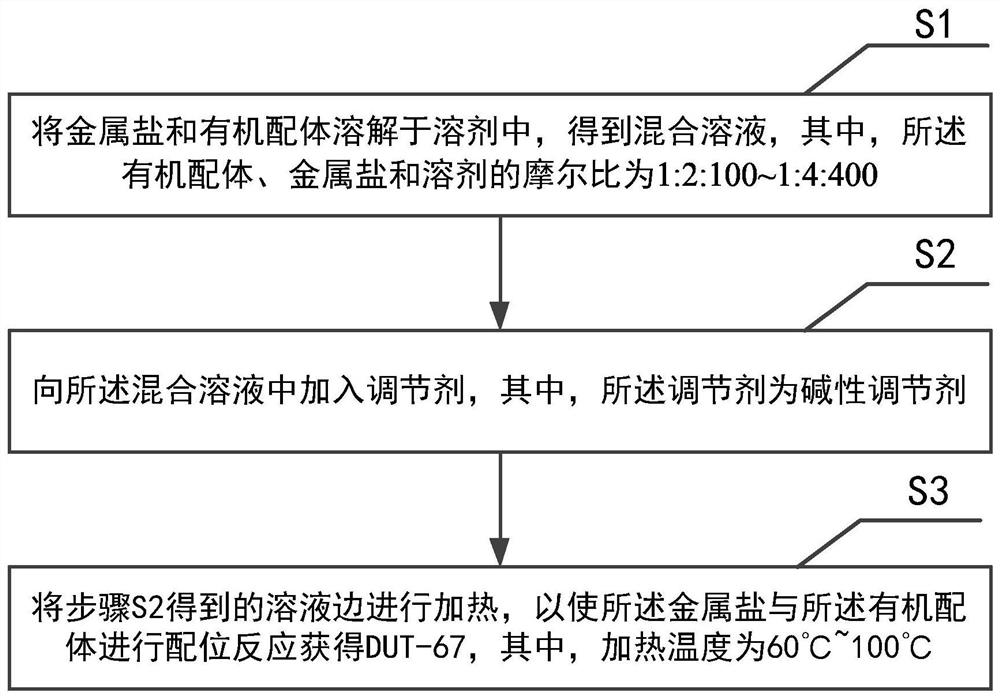

Method used

Image

Examples

Embodiment 1

[0056] The metal salt in this example is zirconium tetrachloride.

[0057] (1) first 81.60mmol zirconium tetrachloride is dissolved in 4.08mol ethanol, stir 10min under 300rpm speed and make it dissolve completely and obtain uniform solution;

[0058] (2) Add 40.80 mmol of organic ligands into the above solution, stir at 300 rpm for 10 min to make it evenly mixed.

[0059] (3) Then add the sodium hydroxide solution of 24.00mmol, stir;

[0060] (4) Heating to 60° C., stirring at 300 rpm for 2 hours to make it react completely, after the reaction is completed, naturally cool to room temperature, centrifuge to separate the solid, and wash away impurities in the solid with 20.40 mol of sodium formate solution;

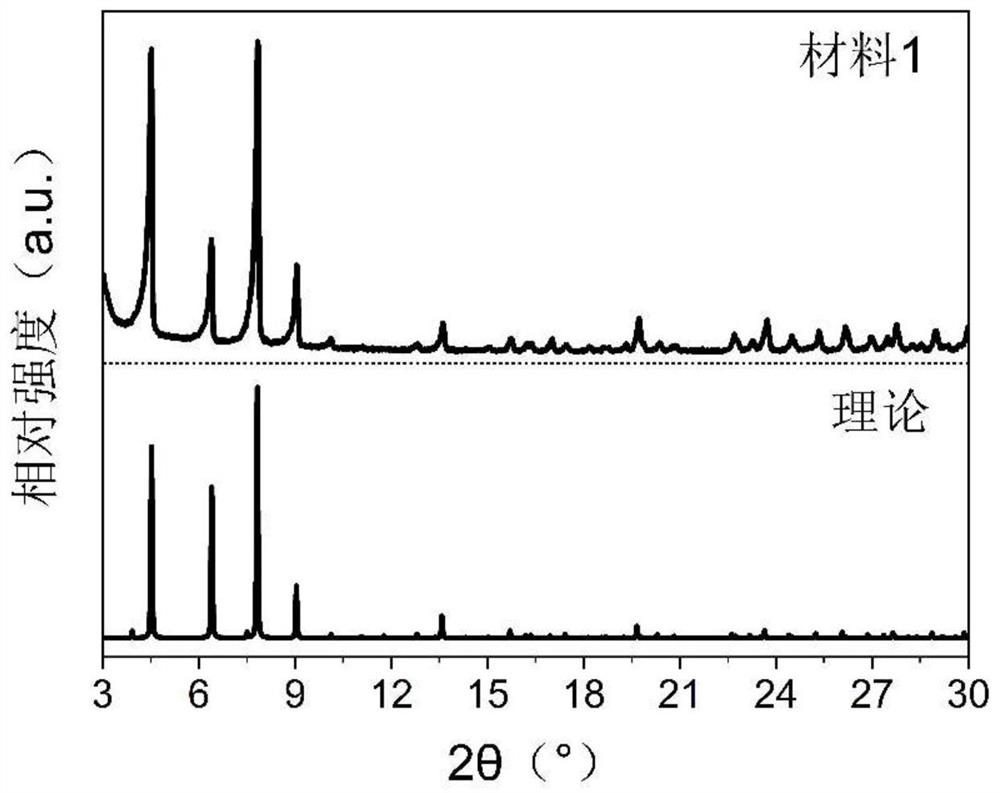

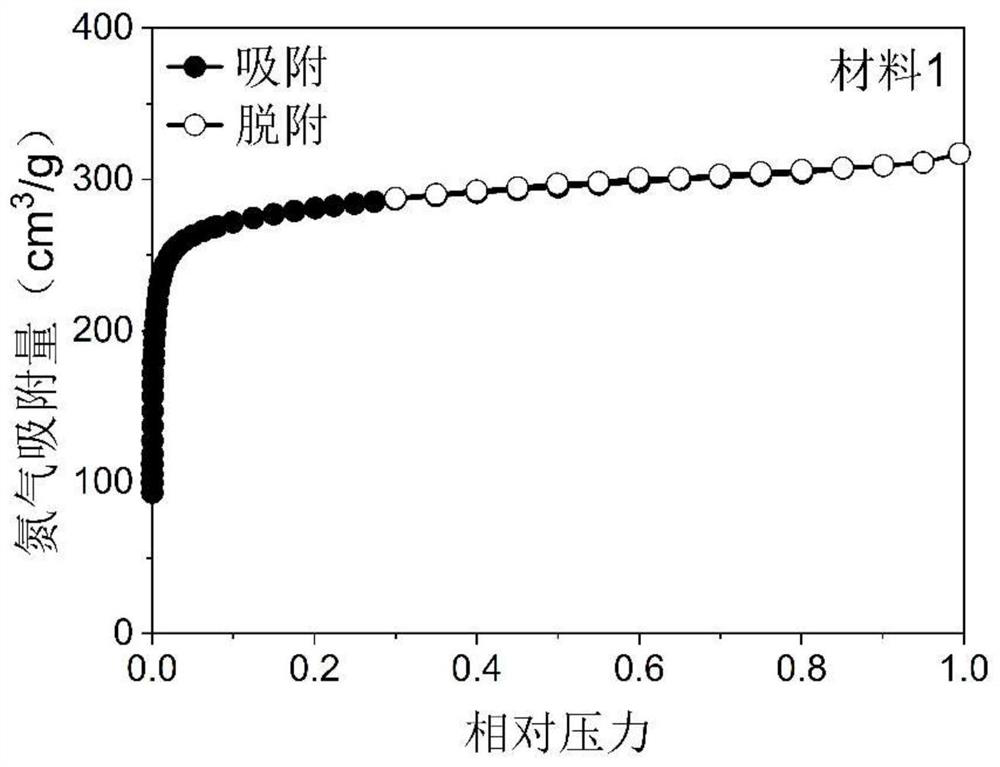

[0061] (5) Dry the obtained solid at 80°C under normal pressure for 9 hours, and then vacuum-dry the obtained solid at 120°C for 9 hours. After drying, 16 g of DUT-67 can be obtained, which is designated as material 1.

Embodiment 2

[0063] The metal salt in this example is zirconium tetrachloride.

[0064] (1) first 81.60mmol zirconium tetrachloride is dissolved in 4.08mol ethanol, stir 10min under 300rpm speed and make it dissolve completely and obtain uniform solution;

[0065] (2) Add 20.40 mmol of organic ligands into the above solution, stir at 300 rpm for 10 min to make it evenly mixed.

[0066] (3) Then add the sodium hydroxide solution of 24.00mmol, stir;

[0067] (4) Heating to 60° C., stirring at 300 rpm for 2 hours to make it react completely, after the reaction is completed, naturally cool to room temperature, centrifuge to separate the solid, and wash away impurities in the solid with 20.40 mol of sodium formate solution;

[0068] (5) Dry the obtained solid under normal pressure at 80° C. for 9 hours, and then vacuum-dry the obtained solid at 120° C. for 9 hours. After drying, 10.5 g of DUT-67 can be obtained.

Embodiment 3

[0070] The metal salt in this example is zirconium tetrachloride.

[0071] (1) first 81.60mmol zirconium tetrachloride is dissolved in 4.08mol ethanol, stir 10min under 300rpm speed and make it dissolve completely and obtain uniform solution;

[0072] (2) Add 27.20 mmol of organic ligands into the above solution, stir at 300 rpm for 10 min to make it evenly mixed.

[0073] (3) Then add the sodium hydroxide solution of 24.00mmol, stir;

[0074] (4) Heating to 60° C., stirring at 300 rpm for 2 hours to make it react completely, after the reaction is completed, naturally cool to room temperature, centrifuge to separate the solid, and wash away impurities in the solid with 20.40 mol of sodium formate solution;

[0075] (5) Dry the obtained solid under normal pressure at 80° C. for 9 hours, and then vacuum-dry the obtained solid at 120° C. for 9 hours. After drying, 13.3 g of DUT-67 can be obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap