Pyrolysis gasification tar conversion and utilization device and method

A technology of tar conversion and pyrolysis gasification, which is applied in the gasification of granular/powdered fuels, the petroleum industry, and the manufacture of combustible gases. It can solve the problems of difficult removal and purification of tar, save investment costs, and speed up oxidation reactions. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

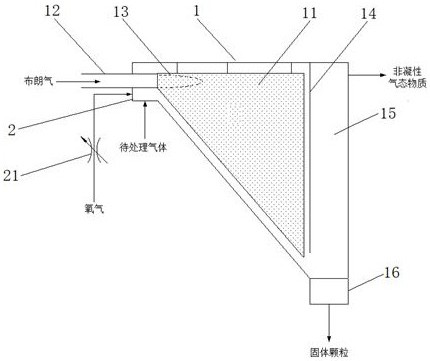

[0030] see figure 1 , a device for converting and utilizing pyrolysis gasification tar, comprising a reaction chamber 1 , an airflow mixer 2 , a heat exchange unit 15 and a slag removal unit 16 .

[0031] The reaction chamber 1 has a gradually expanding cross-section, and an orifice plate 11 is arranged in the reaction chamber 1, and the orifice plate 11 is made of heat storage material resistant to high temperature and corrosion. The orifice plate 11 extends downward along the tube wall of the reaction chamber 1 , the front end of the orifice plate 11 is arranged close to one side of the reaction chamber 1 , and the rear end of the orifice plate 11 is arranged near the other side of the reaction chamber 1 .

[0032] The upper end of one side of the reaction chamber 1 is provided with a Brownian gas channel 12, the inlet of the Brownian gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com