Method for recovering molybdenum in waste catalyst

A waste catalyst and recovery method technology, applied in the fields of environmental protection and resource recovery comprehensive utilization, can solve the problems of long process flow, high energy consumption, waste of resources, etc., and achieve simple process flow, reduced process energy consumption, and short process cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

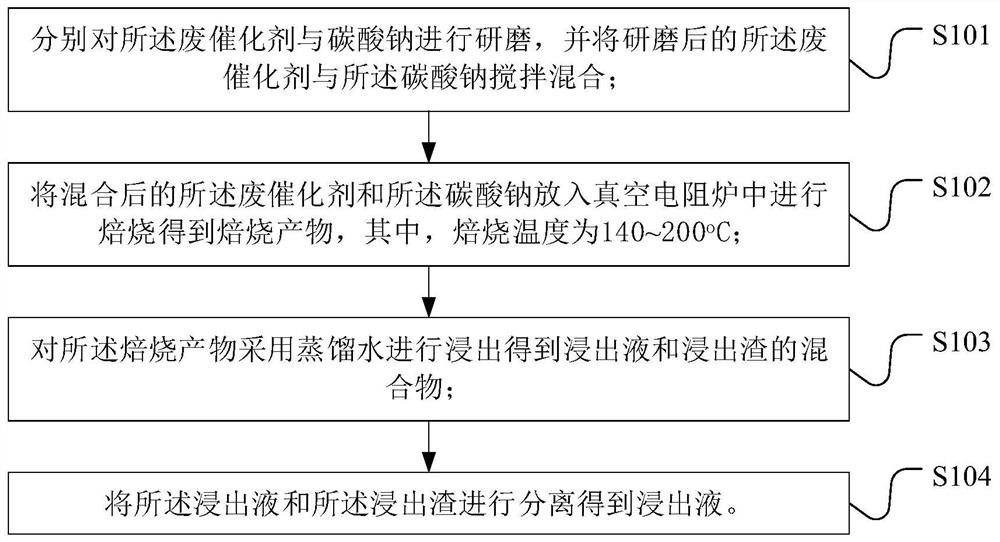

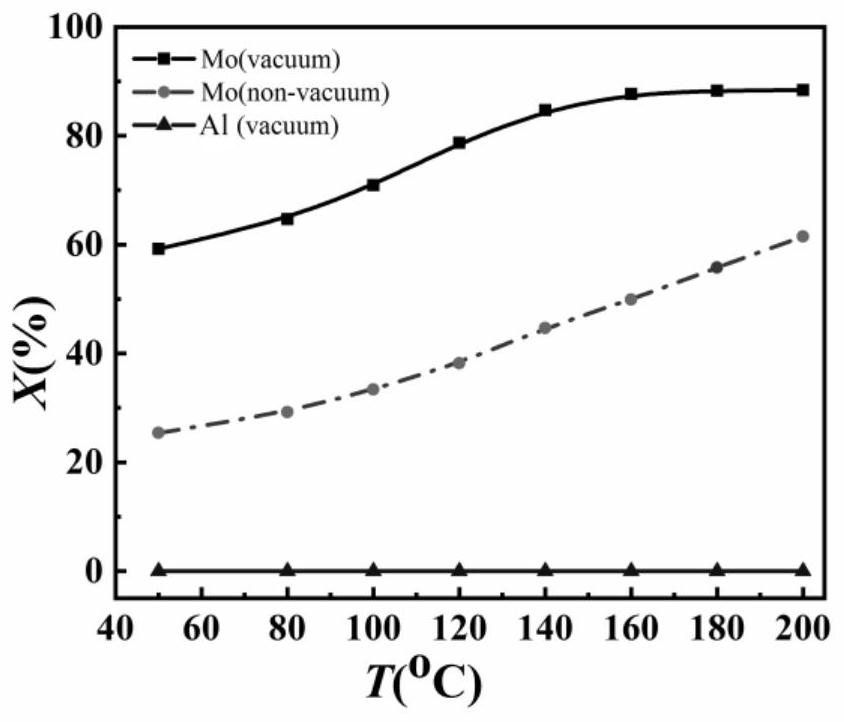

[0056] In the present embodiment, the molybdenum in the waste GDS-30 catalyst is recovered by roasting under vacuum conditions and roasting under non-vacuum conditions respectively, and the recovery steps are as follows:

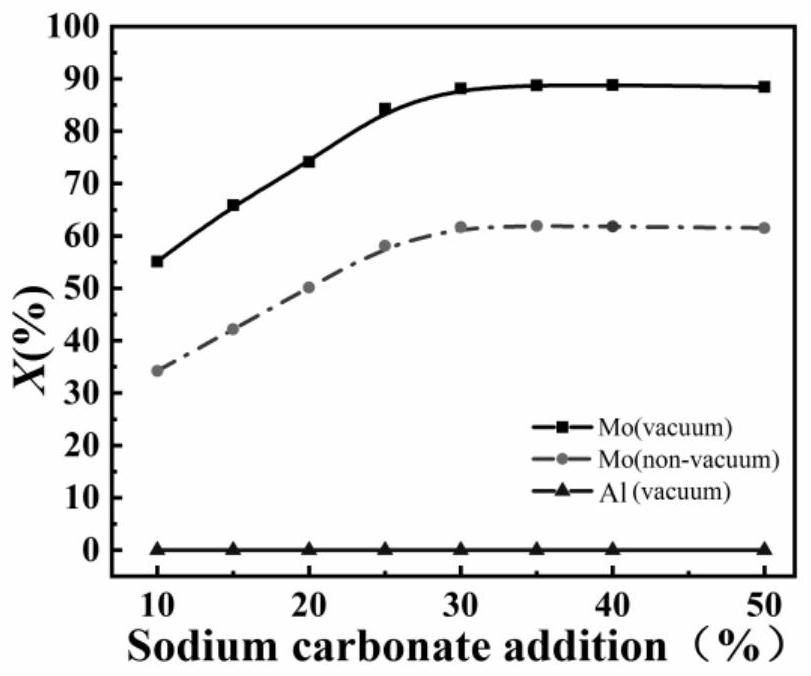

[0057] S1011: Grind the spent GDS-30 catalyst and sodium carbonate to 200 mesh respectively, and stir and mix the ground spent catalyst and the sodium carbonate evenly, wherein the mass of sodium carbonate is 30% of the mass of the spent GDS-30 catalyst %;

[0058] S1021: Roasting the mixed spent GDS-30 catalyst and sodium carbonate to obtain a calcined product, wherein the calcining temperature is 160° C. and the calcining time is 30 minutes;

[0059] S1031: Leaching the roasted product with distilled water to obtain a mixture of leachate and leach residue, wherein the mass ratio of the roasted product to distilled water during leaching is 1:6, the leaching time is 20 min, and the stirring intensity is 300 rpm;

[0060] S1041: Separating the mixture of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com