Preparation method of AlCoCrFeNi series double-phase structure high-entropy alloy

A high-entropy alloy and dual-phase structure technology, applied in the field of metal materials, can solve problems such as poor elongation, achieve high strength, improve structure unevenness, and improve the plasticity of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Select high-purity metals with a purity of 99.99%, including aluminum, cobalt, chromium, iron, and nickel, as raw materials, according to Co: 20.91wt.%, Cr: 18.45wt.%, Fe: 19.82wt.%, Ni : 31.24wt.%, the balance is the ratio of Al to weigh the corresponding metal, put it in the copper crucible of the vacuum arc melting equipment, and use the mechanical pump and the molecular pump to vacuum the arc melting furnace to 3×10 -3 Pa, filled with high-purity argon to 1.6×10 3 Pa, this process is repeated 5 times to fully remove the oxygen in the furnace cavity.

[0046] (2) Vacuum arc melting process is used to melt high-purity metals to obtain ingots. During the process, the ingots are turned over with the help of a mechanical arm and then smelted again. This operation is repeated 5 times to ensure uniform alloy composition. During the first smelting, the current is controlled at 170A to slowly melt the high-purity metal, and during the 2nd to 5th smelting, the current is...

experiment example 1

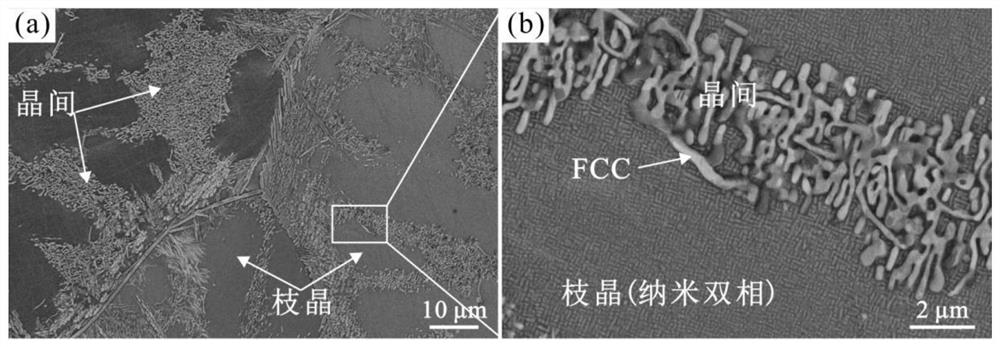

[0054] The high-entropy alloy casting bar microstructure that embodiment 1 step 5 obtains is observed, and the results are shown in figure 1 . in, figure 1 b is figure 1 Enlarged view of the white framed area in a. Depend on figure 1 It can be seen that the as-cast high-entropy alloy has a typical dendrite structure morphology, the dendrite region is a dual-phase nanostructure, and the intergranular region is dominated by FCC phase.

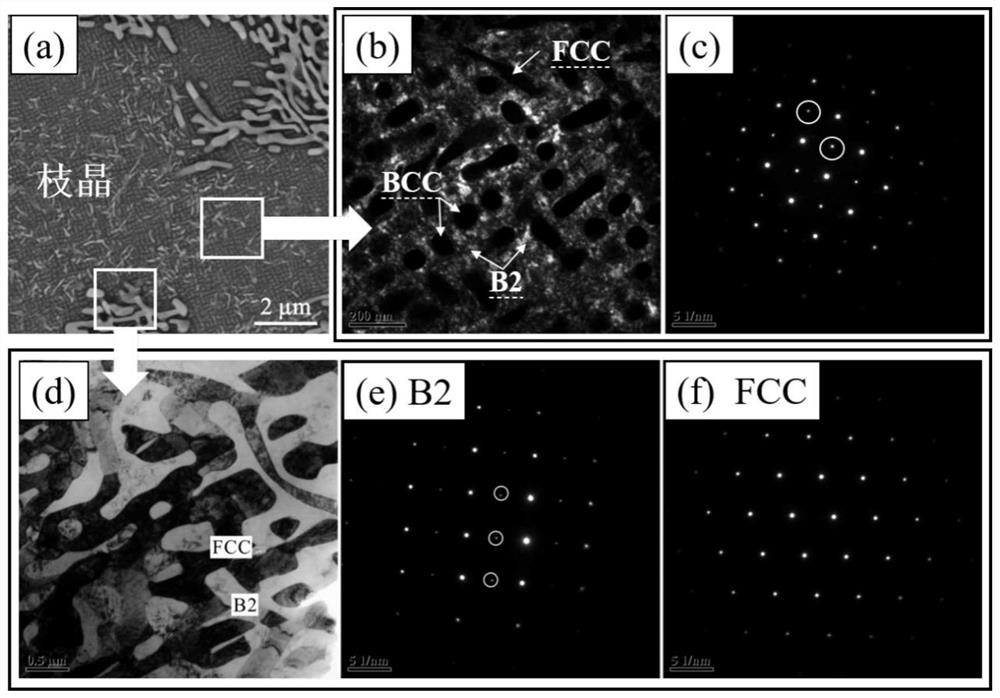

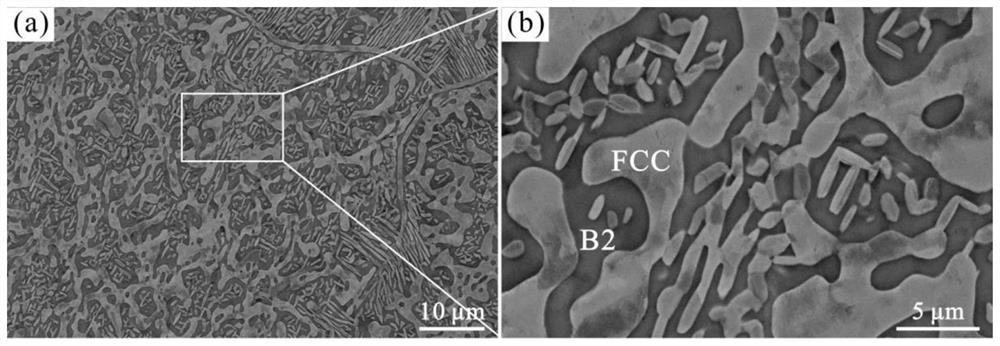

[0055] The microstructure of the AlCoCrFeNi dual-phase structure high-entropy alloy obtained in Comparative Example 1 was observed, and the results are shown in figure 2 . Depend on figure 2 a It can be seen that a new flocculent phase is precipitated in the alloy dendrite area of the heat-treated alloy at 650 °C, and this phase is the FCC phase. figure 2 b&c confirmed that the dendrite region is mainly composed of disordered BCC and ordered B2 nano-duplexes, which is consistent with the dendrite region of the as-cast alloy (see figu...

Embodiment 2

[0062] Concrete method is the same as embodiment 1, and difference only is that heat treatment time is 2 hours in step (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com