Fine-grain hot-rolled steel plate and strip and preparation method thereof

A hot-rolled sheet, fine-grain technology, applied in metal rolling, metal rolling, heat treatment equipment, etc., to reduce production costs, avoid a large number of additions, and improve strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

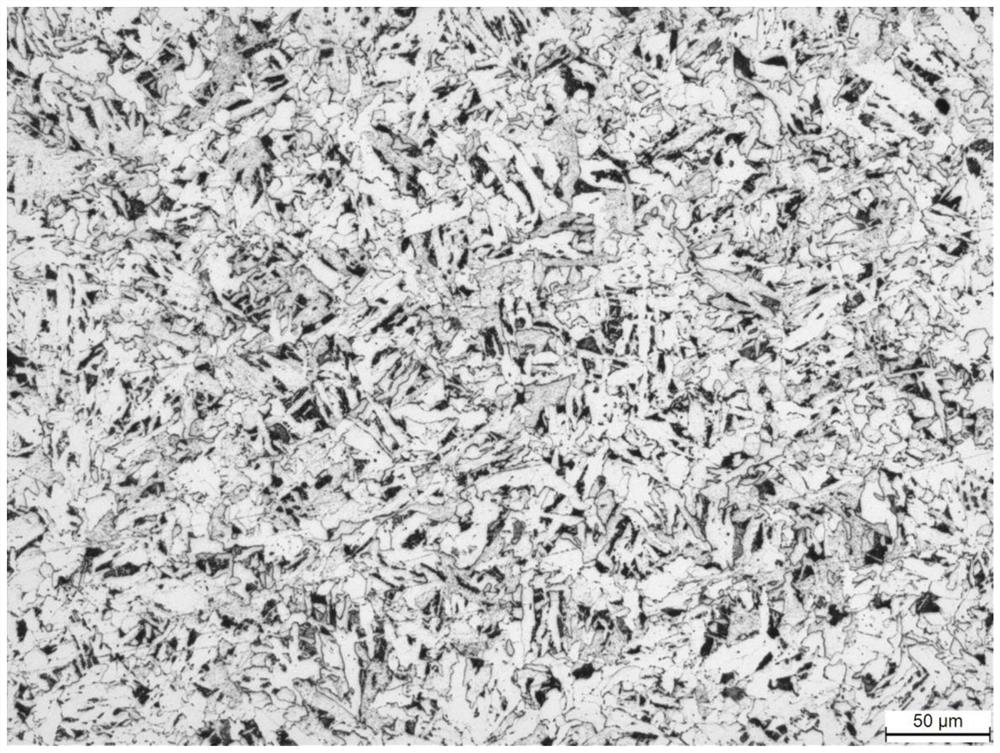

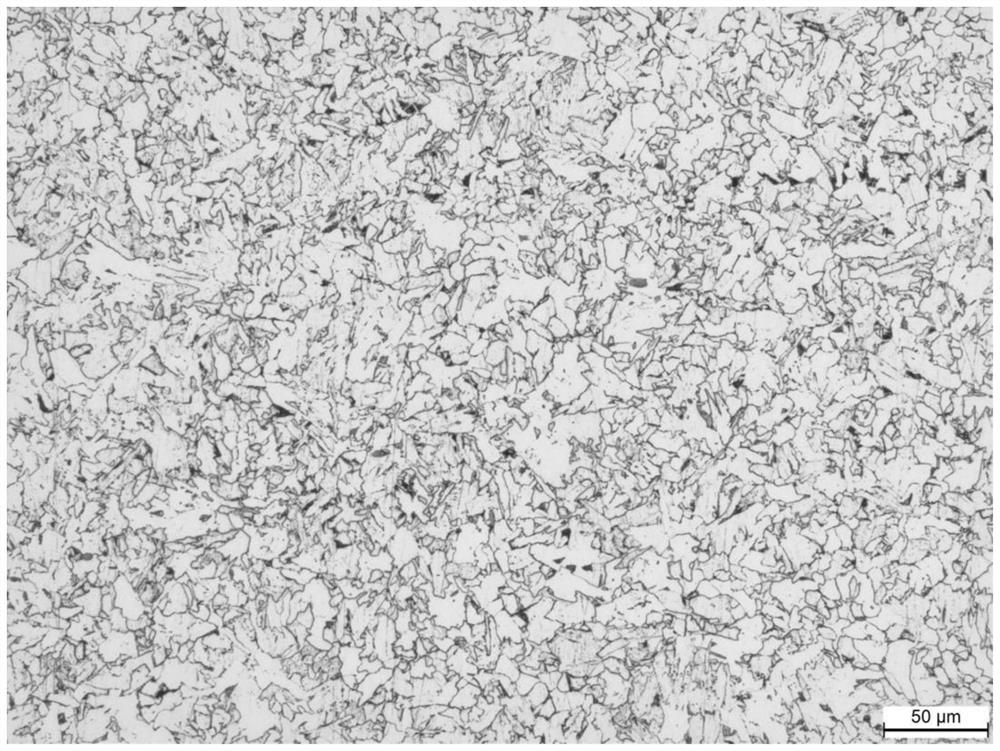

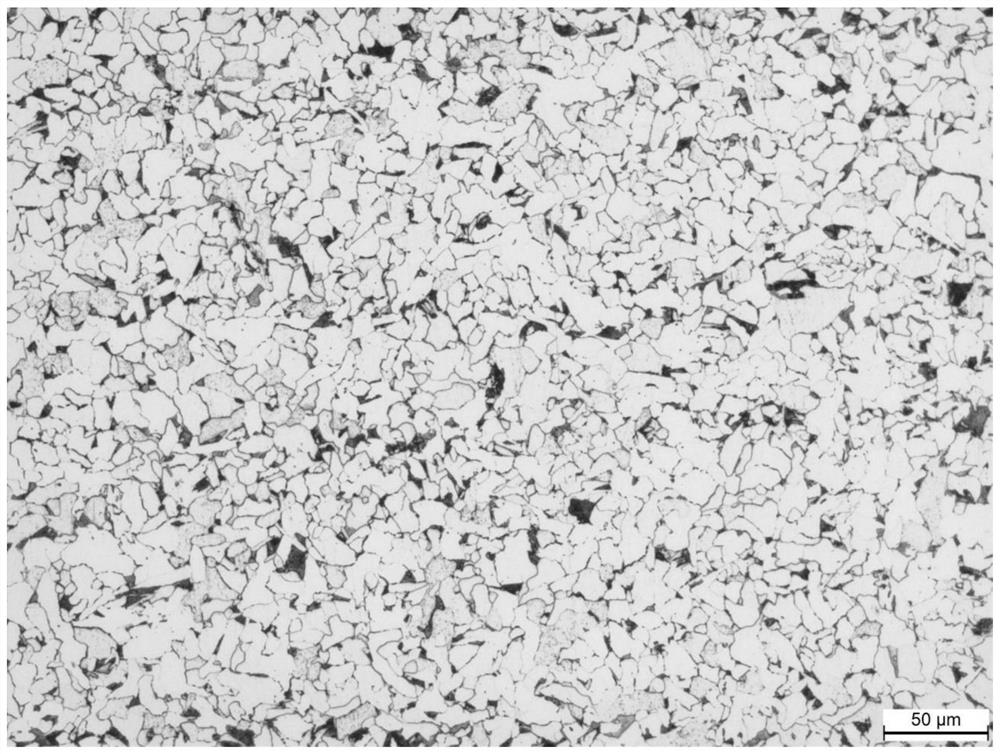

Image

Examples

preparation example Construction

[0079] When the fine-grained element is B, a method for preparing a fine-grained hot-rolled strip steel comprises the following steps:

[0080] Step 1: Smelting

[0081] Use a converter or an electric furnace to melt molten iron and / or scrap steel into molten steel. When the temperature of the molten steel reaches 1600-1700°C and the mass fraction of carbon in the molten steel is 0.02-0.15%, the mass fraction of phosphorus is 0.001-0.035%, and the mass fraction of sulfur is 0.001- When tapping at 0.045%, add one or more of silicon, manganese, aluminum, calcium, barium or other deoxidizers commonly used in steelmaking to the ladle during tapping; control the mass percentage of dissolved oxygen in molten steel after tapping The content range is 0.001~0.015%;

[0082] Step 2: Refining and Continuous Casting

[0083] The molten steel after tapping is refined into LF refining, and RH refining or VD refining can also be carried out after LF refining; during the refining process, d...

Embodiment 1

[0112] This embodiment is a method for preparing fine-grained hot-rolled strip steel, comprising the following steps:

[0113] Step 1: Smelting

[0114] Use a converter to smelt molten iron and steel scrap (mixing mass ratio 1:1) into molten steel. When the temperature of molten steel reaches 1650°C and the mass fraction of carbon in molten steel is 0.05%, the mass fraction of phosphorus is 0.015%, and the mass fraction of sulfur is 0.035%. Tapping, adding a mixture of silicon, manganese and aluminum (mass ratio 1:1:1) for deoxidation during the tapping process, the dissolved oxygen mass fraction of molten steel is 0.005%;

[0115] Step 2: Refining and Continuous Casting

[0116] The molten steel after tapping is subjected to LF refining. During the refining process, deoxidation and desulfurization are used to remove impurities and temperature adjustment components. The refining time is 40 minutes; Core wire, titanium-boron cored wire is made by mixing and filling alloy powd...

Embodiment 2

[0129] A method for preparing fine-grained hot-rolled strip steel, comprising the following steps:

[0130] Step 1: Smelting

[0131] Use an electric furnace to smelt scrap steel into molten steel. When the temperature of molten steel reaches 1670°C and the mass fraction of carbon in the molten steel is 0.03%, the mass fraction of phosphorus is 0.01%, and the mass fraction of sulfur is 0.015%, the steel is tapped, and the silicon and manganese mixture is added during the tapping process. (mass ratio is 1:1) for deoxidation, molten steel dissolved oxygen mass fraction 0.01%;

[0132] Step 2: Refining and Continuous Casting

[0133] The molten steel after tapping is subjected to LF refining and RH refining. During the refining process, deoxidation and desulfurization removes inclusions and temperature adjustment components. The LF refining time is 35 minutes, and the RH refining time is 30 minutes. After LF refining, the dissolved oxygen mass percentage in molten steel is 0.000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com