Surface-enhanced Raman scattering substrate and preparation method and application thereof

A surface-enhanced Raman and substrate technology, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of difficult to obtain the deposition layer of nano-silver particles, high cost of SERS substrate preparation, and inability to use SERS detection, etc., to achieve performance Superior, high sensitivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of surface-enhanced Raman scattering substrate:

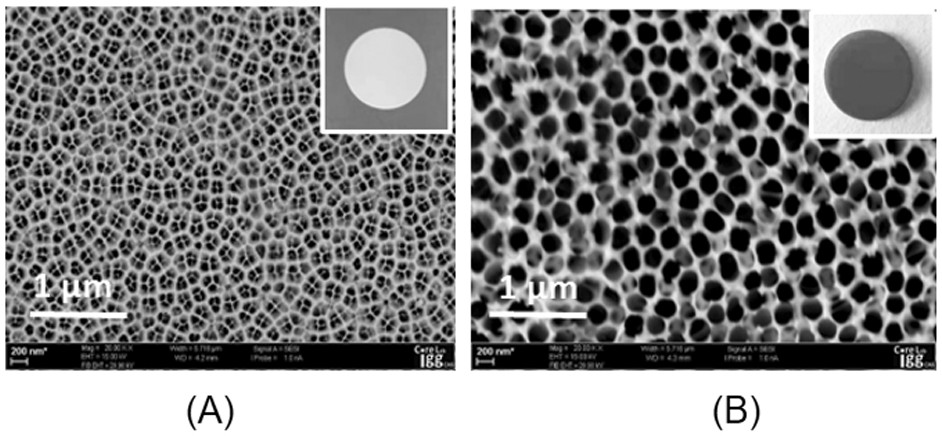

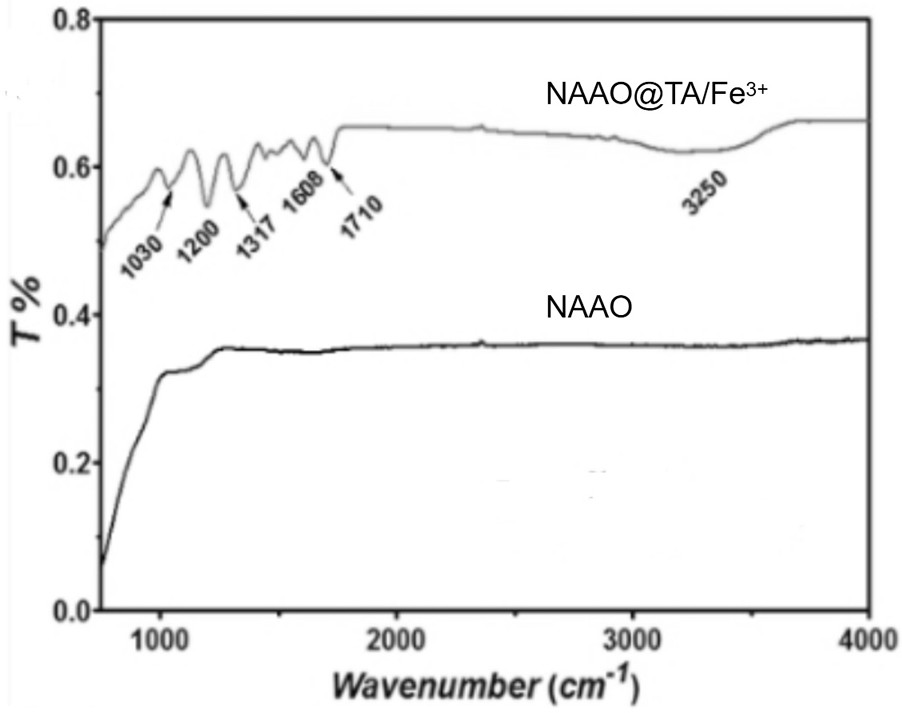

[0067] S1. NAAO@TA / Fe 3+ Preparation of the NAAO film: Soak the NAAO film in an aqueous solution of tannic acid at pH=7 for 1 hour, take it out, wash off the excess tannic acid on the surface with ultrapure water, and obtain NAAO@TA, and place the NAAO@TA in a 0.001mol / L FeCl 3 Incubate in an aqueous solution, take it out after 1 min, and soak it again in an aqueous solution of tannic acid at pH=7, so that Fe 3+ Complexation with tannic acid to obtain NAAO@TA / Fe 3+ ;

[0068] S2. Preparation of silver ammonia solution: 0.17gAgNO 3 Dissolve in 9.7mL water, add 0.3mL ammonia solution dropwise to obtain 0.1mol / L transparent silver ammonia solution;

[0069] S3. Preparation of surface-enhanced Raman scattering substrate: the NAAO@TA / Fe 3+ Soaked in 2mL 0.1mol / L silver ammonia solution, deposited in situ at 60°C for 4h to form NAAO@AgNS1.

Embodiment 2

[0071] Preparation of surface-enhanced Raman scattering substrate:

[0072] S1. NAAO@TA / Fe 3+ Preparation of the NAAO film: Soak the NAAO film in an aqueous solution of tannic acid at pH=7 for 1 hour, take it out, wash off the excess tannic acid on the surface with ultrapure water, and obtain NAAO@TA, and place the NAAO@TA in a 0.001mol / L FeCl 3 Incubate in an aqueous solution, take it out after 1 min, and soak it again in an aqueous solution of tannic acid at pH=7, so that Fe 3+ Complexation with tannic acid to obtain NAAO@TA / Fe 3+ ;

[0073] S2. Preparation of silver ammonia solution: 0.17gAgNO 3 Dissolve in 9.7mL water, add 0.3mL ammonia solution dropwise to obtain 0.1mol / L transparent silver ammonia solution;

[0074] S3. Preparation of silver growth medium: add 1mL 5mmol / L silver ammonia solution, 0.5mL 50mmol / L ascorbic acid, 0.5mL 1% (w / v) sodium citrate aqueous solution into 12.5mL water, mix well to obtain silver growth medium ;

[0075] S4. Preparation of surf...

Embodiment 3

[0089] Example 3 Surface-enhanced Raman scattering substrate NAAO@AgNS2 for testing fluoroacetic acid

[0090] S1. After incubating the surface-enhanced Raman scattering substrate NAAO@AgNS2 prepared in Example 2 with 0.001mol / L KSCN aqueous solution for 30min, the SCN - As internal standard, take it out, wash with pure water, and carry out quantitative determination;

[0091]S2. Add 0.01μmol / L-0.6μmol / L standard solution of fluoroacetic acid and 0.6μmol / L thiosalicylic acid into 0.2mL buffer solution containing 1.0mmol / L NaOH and 1.0mmol / L KI, at 90℃ After reacting for 30 minutes, the solution was transferred to a circular quartz measurement cell with a surface-enhanced Raman scattering substrate NAAO@AgNS2. After incubation for 1 hour, a random area on the surface-enhanced Raman scattering substrate film was selected under a microscope, and it was found that the There is basically no change in the Mann intensity, indicating that the substrate has a large area of uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com