Magnetic refrigeration material, preparation method and application thereof

A technology of magnetic refrigeration materials and polycrystalline materials, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of long cycle and high energy consumption, and achieve short reaction cycle, low energy consumption, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

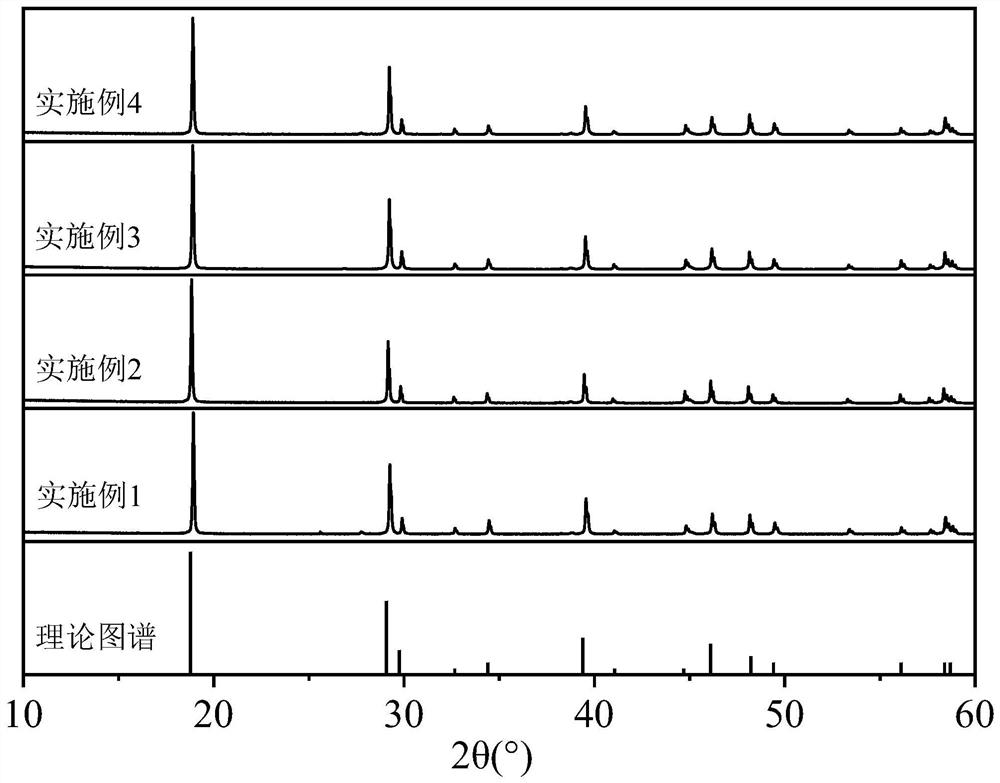

Embodiment 1

[0069] This embodiment provides a method for preparing a magnetic refrigeration material, the preparation method comprising the following steps:

[0070] (1) Weigh LiF and GdF according to the ratio of the amount of substances to 1:1 3 , grind to obtain a mixture with an average particle size of 100 μm;

[0071] (2) Put the mixture described in step (1) into the first crucible made of corundum, and cover the lid of the first crucible;

[0072] (3) The first crucible is put into the second crucible made of graphite, the outside of the first crucible is covered with graphite with an average particle size of 100 μm, and the lid of the second crucible is covered;

[0073] (4) The second crucible was placed in a tube furnace, and sintered at 1200° C. for 10 minutes under an argon atmosphere to obtain a magnetic refrigeration material.

Embodiment 2

[0075] This embodiment provides a method for preparing a magnetic refrigeration material, the preparation method comprising the following steps:

[0076] (1) Weigh LiF and GdF according to the ratio of the amount of substances to 1.8:1 3 , ball milled to obtain a mixture with an average particle size of 50 μm;

[0077] (2) Put the mixture described in step (1) into the first crucible made of boron nitride, and cover the lid of the first crucible;

[0078] (3) The first crucible is put into the second crucible made of corundum, the outside of the first crucible is covered with carbon black with an average particle size of 500 μm, and the lid of the second crucible is covered;

[0079] (4) The second crucible was placed in a muffle furnace, and sintered at 1000° C. for 40 minutes in an air atmosphere to obtain a magnetic refrigeration material.

Embodiment 3

[0081] This embodiment provides a method for preparing a magnetic refrigeration material, the preparation method comprising the following steps:

[0082] (1) Weigh LiF and GdF according to the ratio of the amount of substances to 1.4:1 3 Powder, mixed to obtain a mixture with an average particle size of 100 μm;

[0083] (2) Put the mixture described in step (1) into the first crucible made of graphite, and cover the lid of the first crucible;

[0084] (3) The first crucible is put into the second crucible made of zirconia, the outside of the first crucible is covered with activated carbon with an average particle size of 200 μm, and the lid of the second crucible is covered;

[0085] (4) The second crucible was placed in a vacuum furnace, and sintered at 800° C. for 60 min in a nitrogen atmosphere to obtain a magnetic refrigeration material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum magnetic entropy change | aaaaa | aaaaa |

| Maximum magnetic entropy change | aaaaa | aaaaa |

| Maximum magnetic entropy change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com