Fireproof thermal insulation material as well as preparation method and application thereof

A technology for thermal insulation materials and coatings, which is applied in textiles and papermaking, fiber processing, electrical components, etc., can solve the problems of cumbersome preparation methods and poor tear strength of silicone packages, and achieves simple preparation methods, excellent high temperature resistance, The effect of good mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

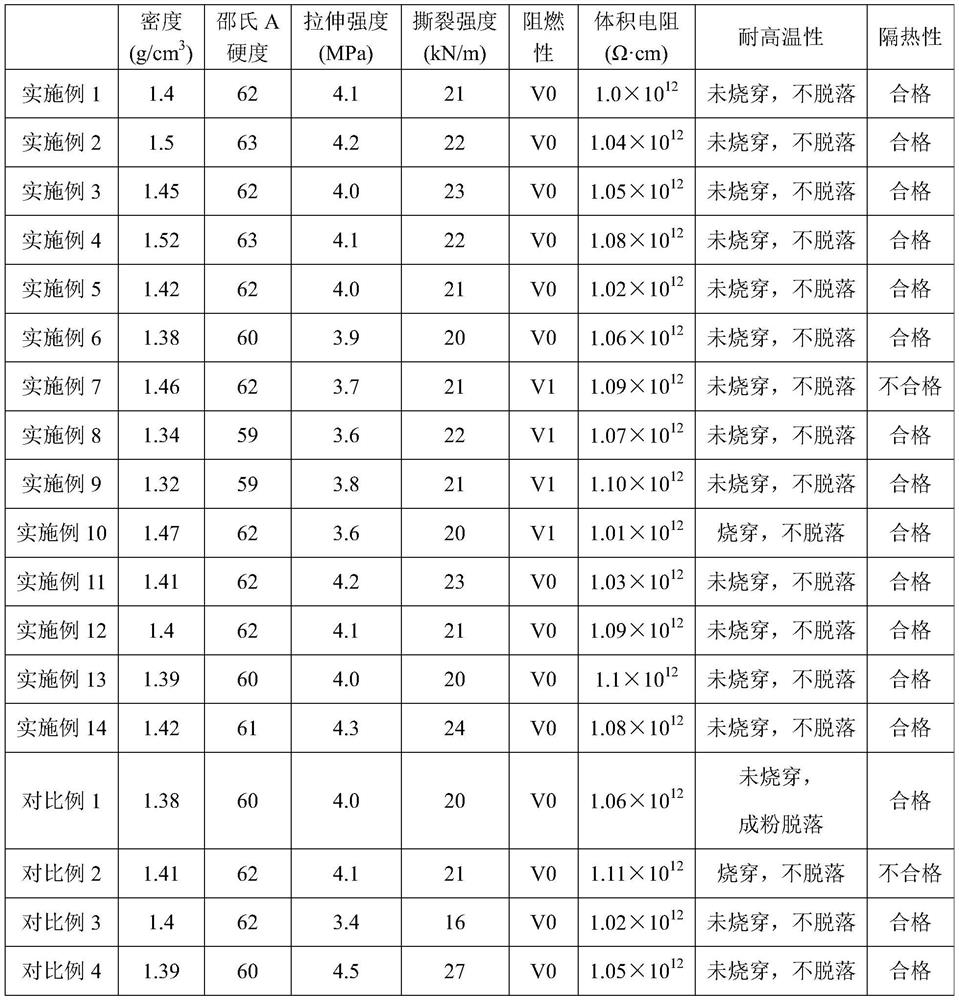

Examples

Embodiment 1

[0078] This embodiment provides a fire-proof and heat-insulating material and a preparation method thereof. The fire-proof and heat-insulating material includes a base layer and a coating layer that fit together; the base layer is a glass fiber cloth layer with a thickness of 0.5 mm, and the coating layer is The thickness is 0.5mm;

[0079] The paint layer is prepared from paint;

[0080] The coating includes the following components in parts by weight: 25 parts of vinyl raw rubber, 28 parts of fumed silica, 50 parts of flame retardant, 6 parts of porcelain-forming filler, 3 parts of vinyltrimethoxysilane, 2,5 - 2 parts of dimethyl-2,5-bis (tert-butyl peroxy) hexane, 0.5 part of platinum catalyst and 0.7 part of 1-ethynyl cyclohexanol; the flame retardant consists of decabromodiphenyl ether and Aluminum hydroxide is composed in a mass ratio of 2:1; the porcelain-forming filler is composed of mica powder, silicon micropowder and glass powder in a mass ratio of 1:1:1.

[0081]...

Embodiment 2

[0088] This embodiment provides a fire-proof and heat-insulating material and a preparation method thereof. The fire-proof and heat-insulating material includes a base layer and a paint layer that fit together; the base layer is a glass fiber cloth layer with a thickness of 0.8 mm, and the paint layer is The thickness is 0.7mm;

[0089]The paint layer is prepared from paint;

[0090] The coating includes the following components in parts by weight: 28 parts of vinyl raw rubber, 30 parts of fumed silica, 55 parts of flame retardant, 3 parts of glass powder, 1-5 parts of vinyl triethoxysilane, over 1 part of di-tert-butyl oxide, 0.3-1 part of platinum catalyst and 0.3 part of dibutyl maleate; the flame retardant is composed of decabromodiphenylethane and aluminum hydroxide in a mass ratio of 1:1.

[0091] The preparation method of the above-mentioned fire-proof and heat-insulating material comprises the following steps:

[0092] (1) Knead vinyl raw rubber and fumed silica for ...

Embodiment 3

[0098] This embodiment provides a fire-proof and heat-insulating material and a preparation method thereof. The fire-proof and heat-insulating material includes a base layer and a paint layer that fit together; the base layer is a glass fiber cloth layer with a thickness of 0.2 mm, and the paint layer is The thickness is 0.3mm;

[0099] The paint layer is prepared from paint;

[0100] The coating comprises the following components in parts by weight: 20 parts of vinyl raw rubber, 20 parts of fumed silica, 40 parts of flame retardant, 8 parts of mica powder, vinyl tris(2-methoxyethoxy) 1 part of silane, 3 parts of dicumyl peroxide, 0.3 part of platinum catalyst and 0.5 part of methyl-1-butyn-3-alcohol; the flame retardant consists of tetrabromobisphenol A and aluminum hydroxide in mass ratio 3:1 composition.

[0101] The preparation method of the above-mentioned fire-proof and heat-insulating material comprises the following steps:

[0102] (1) Knead vinyl raw rubber and fum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com