A kind of resin Mongolian medicine powder formula granule and preparation method thereof

A technology of formula granules and resins, which is applied in pharmaceutical formulas, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of easy pollution, difficulty in taking Mongolian medicine, deterioration, etc., and achieve good stability. , Solve the effect of easy pollution and deterioration, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

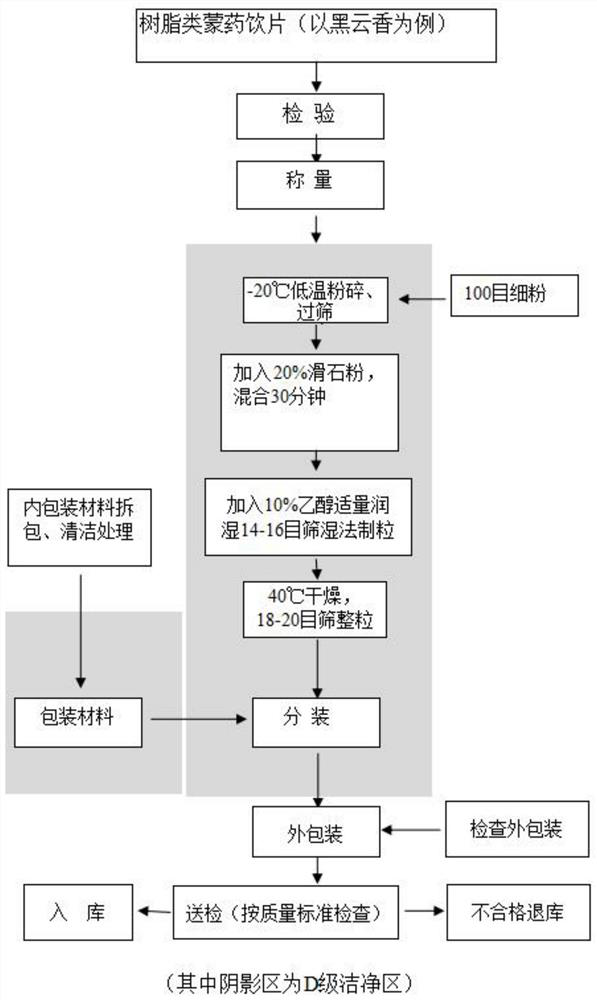

[0031] The present invention also provides a method for preparing resin-based Mongolian medicine powder formula granules described in the above scheme, comprising the following steps:

[0032] The resinous Mongolian medicine is pulverized at low temperature and sieved to obtain the resinous Mongolian medicine raw powder;

[0033] The resin-based Mongolian medicine powder, talcum powder and ethanol are mixed for wet granulation, and the obtained wet granules are dried to obtain the resin-type Mongolian medicine powder formula granules.

[0034] In the invention, the resinous Mongolian medicine is pulverized at low temperature and then sieved to obtain the original powder of the resinous Mongolian medicine. In the present invention, the temperature of the low-temperature pulverization is -20 to -40°C, more preferably -20°C; the resinous Mongolian medicine has a certain astringency and viscosity, and the present invention uses low-temperature pulverization to increase the resinou...

Embodiment 1

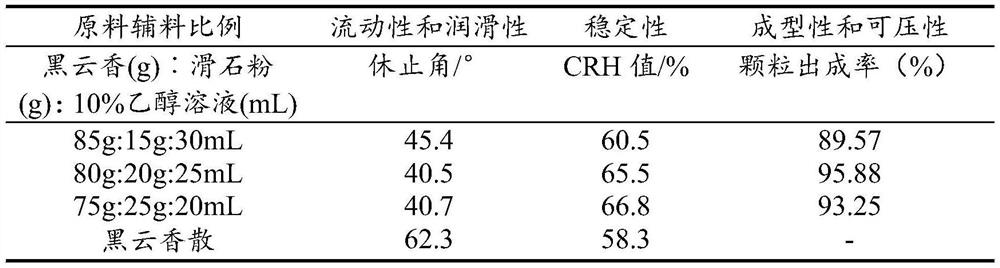

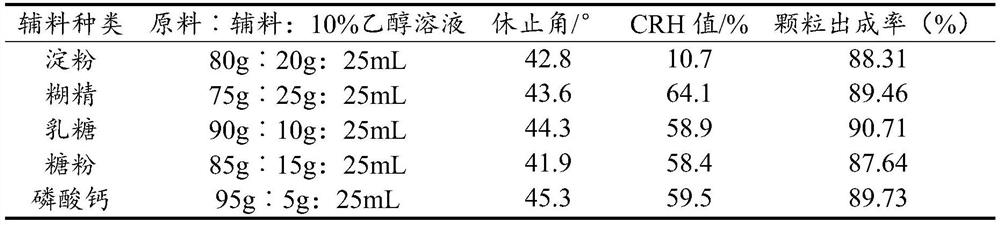

[0043] Preparation of Heiyunxiang powder formula granules: raw materials are Heiweixiang powder, talcum powder and 10% ethanol solution (subsequently referred to as 10% ethanol solution), the dosage ratio of raw materials is shown in Table 1.

[0044] The preparation method is as follows: weigh the black kelp and crush it at a low temperature of -20°C, and sieve the crushed material with an electromagnetic vibrating sieve to obtain 100-mesh black kelp powder; mix the black kelp powder with talc powder 30min, then add 10% ethanol solution for mixing to obtain soft material; extrude the soft material through a 14-mesh sieve, dry the obtained wet granules at 40°C until the water content is less than 8%, and then use a 18-mesh sieve to sieve granules to obtain Heiyunxiang formula granules; the Heiyunxiang powder formula granules are subpackaged with inner packaging materials, then wrapped in outer packaging, and put into storage after passing the inspection. For the preparation pr...

Embodiment 2

[0058] This experiment tests the effect of the temperature of low-temperature grinding on the grinding effect: Take three parts of Heiyunxiang with the same mass (200g) and grind them at different low temperatures. The grinding time is 20 minutes, and the powder is taken out for particle size distribution analysis. The results are shown in the table below .

[0059] Table 3 Effect of different low temperature conditions on crushing efficiency

[0060]

[0061] Resin Mongolian medicines have a certain degree of astringency and viscosity. The present invention adopts the method of low-temperature crushing to increase its brittleness and improve crushing efficiency. The particle size of the granulated powder of the formula granules is 100 mesh is the best. According to the data in Table 3, it can be seen that the temperature of low-temperature pulverization has a significant impact on the pulverization effect. When the pulverization temperature is -5°C, the 100 mesh powder in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com