Formaldehyde removal filtering screen as well as preparation method and application thereof

A filter and formaldehyde technology, applied in the field of air purification, can solve the problems of reducing the formaldehyde removal activity of MnO2, reducing the activity of manganese oxides, breeding bacteria, and general formaldehyde removal effect, so as to improve the formaldehyde removal ability, low wind resistance, and avoid dust. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The present invention also provides a method for preparing the formaldehyde-removing filter screen described in the foregoing embodiments, comprising the following steps:

[0076] (1) Carry out pretreatment to substrate;

[0077] (2) Coating an adhesive layer on the surface of the vent hole inner wall of the substrate treated in step (1) by spraying or soaking;

[0078] (3) Spray the aldehyde-removing particles onto the surface of the adhesive layer by means of powder electrostatic spraying, and form a layer of aldehyde-removing particles after drying to obtain a filter body comprising a substrate, an adhesive layer and an aldehyde-removing particle layer;

[0079] (4) Cutting the filter body according to the required size, and bonding the frame to the outer periphery of the filter body to obtain the formaldehyde-removing filter.

[0080] In the preparation process of the formaldehyde-removing filter screen of the present invention, the method of coating the adhesive l...

Embodiment 1

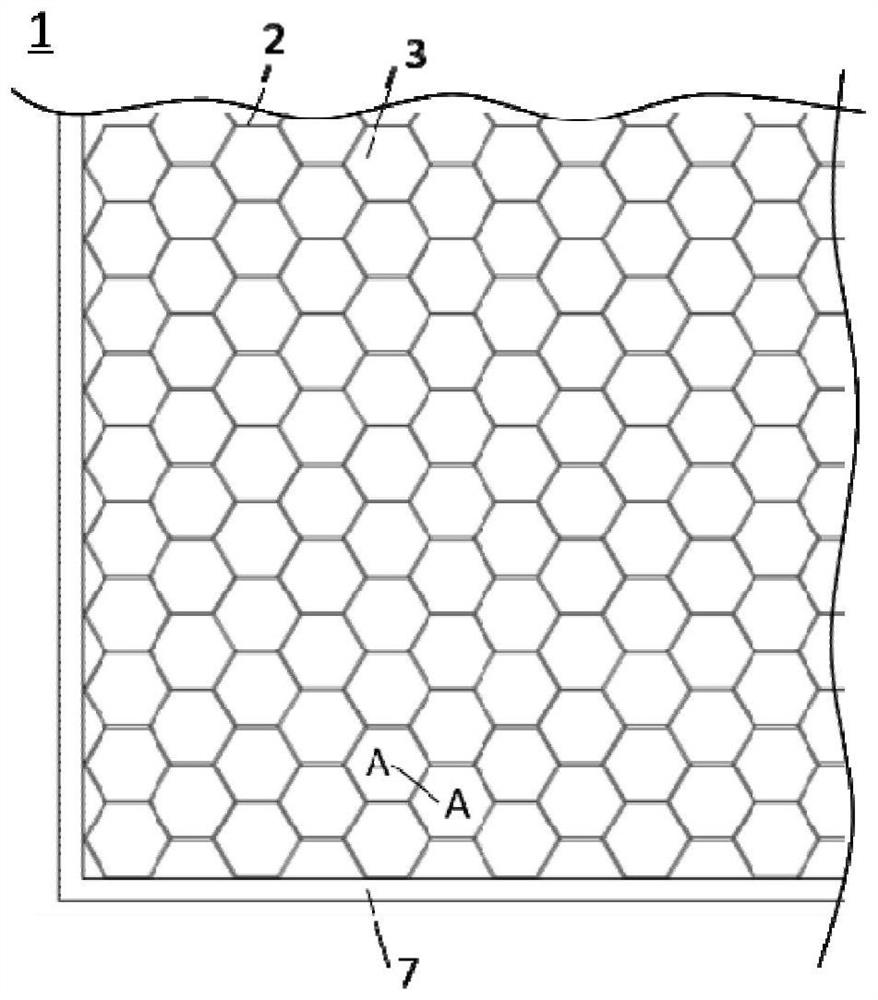

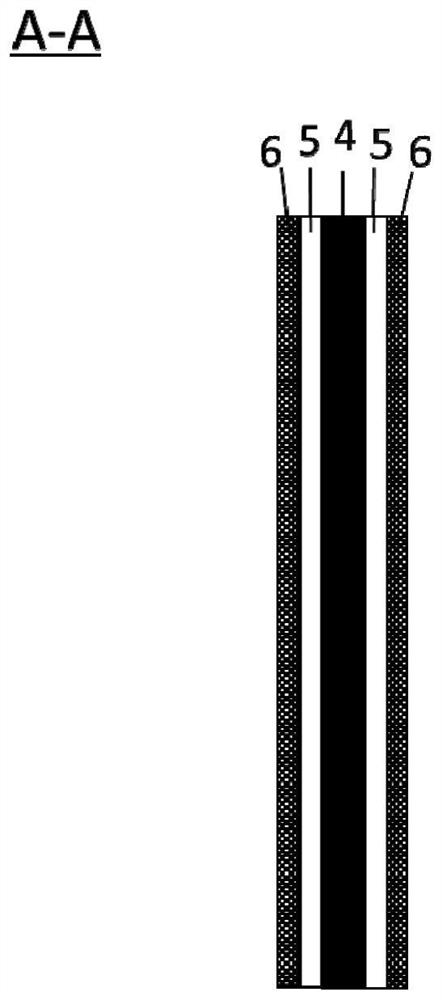

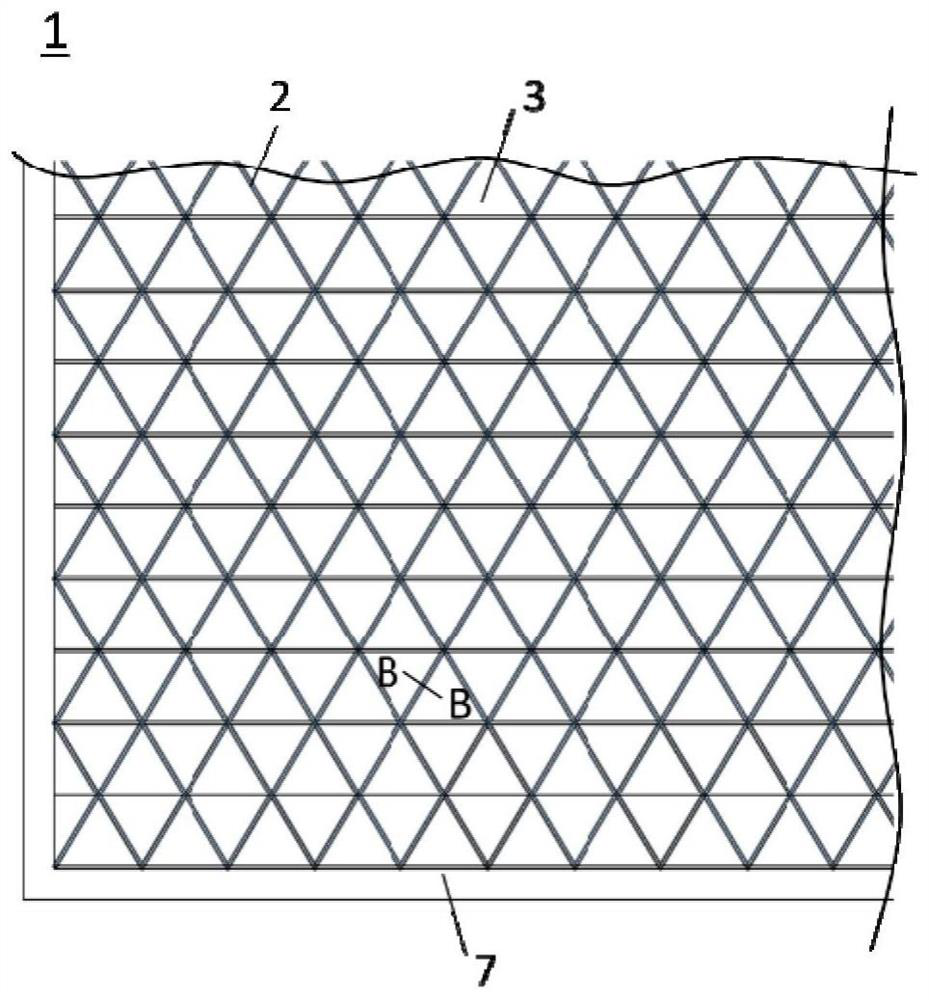

[0096] The formaldehyde removal filter screen 1 of the present embodiment, such as Figure 1-2 As shown, it includes a filter body and a frame 7 located on the periphery of the filter body;

[0097] The filter body includes:

[0098] a substrate 2, the substrate 2 has a plurality of ventilation holes 3 extending along the thickness direction;

[0099] An adhesive layer 5, the adhesive layer 5 is arranged on the surface of the inner wall 4 of the vent hole of the substrate 2;

[0100] The aldehyde-removing particle layer 6 , the aldehyde-removing particle layer 6 is made of nanoscale aldehyde-removing particles, and adhered to the surface of the adhesive layer 5 .

[0101] The preparation method of the formaldehyde-removing filter screen of the present embodiment comprises the following steps:

[0102] 1) Place the aluminum honeycomb core substrate with a thickness of 5 mm, a mesh number of 200 mesh, and a hexagonal cross-sectional shape of the vent hole in the acidic degrea...

Embodiment 2

[0107] The structure and preparation method of the formaldehyde-removing filter screen of this embodiment are basically the same as that of Example 1, the difference is that in step 2) of the preparation method of the formaldehyde-removing filter screen of this embodiment, 20 parts by mass of water-based polyurethane adhesive, 0.1 Parts by mass of the cellulose thickener and 79.9 parts by mass of water were evenly mixed to form an adhesive layer mixed solution with a viscosity of 1050 mPa·s, and then the base material treated in step (1) was placed in the mixed solution for 3 minutes, Lift the substrate and blow off the excess slurry to form a structure including the substrate and the adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com