Laser seal welding method for oxygen-free copper shell and oxygen-free copper cover plate

An oxygen-free copper and laser spot welding technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of being easily affected by the surface state of the workpiece, large particle splashes and holes, and difficult to form a stable molten pool etc. to achieve continuous laser welding process parameter optimization, stable solder spot diameter, and pulse laser welding process parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

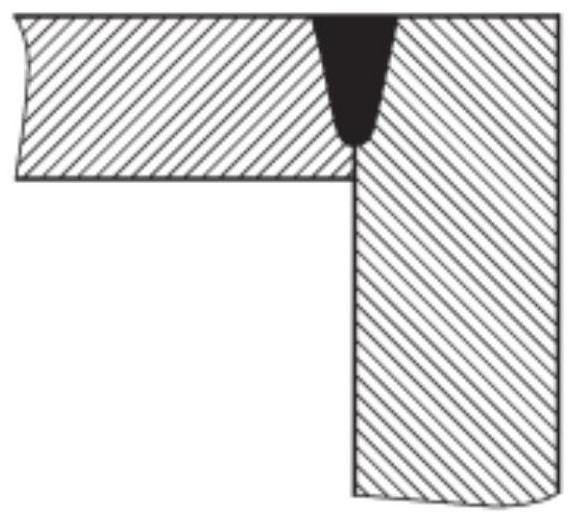

[0030] In this embodiment, the oxygen-free copper shell to be laser sealed and welded is 30mm×30mm, and the inner cavity volume is about 3.7cm 3 , the oxygen-free copper shell includes electroplated nickel, gold oxygen-free copper shell and electroplated nickel, gold oxygen-free copper cover plate, the welding joint adopts the method of locking the bottom self-centering joint, specifically as figure 1 As shown, the thickness of the cover plate is 1mm, and the fit gap between the shell and the cover plate is 0.08mm.

[0031] The laser sealing and welding method for the above-mentioned oxygen-free copper shell comprises the following steps:

[0032] (1) Cleaning: Soak the oxygen-free copper shell with methanol and isopropanol in sequence. After soaking, wipe the inside and outside of the oxygen-free copper shell with dust-free paper to remove oil stains on the surface of the shell, and then use nitrogen gas (of course, it can also be cleaned). is other protective gas) to dry th...

Embodiment 2

[0040] In this embodiment, the oxygen-free copper shell to be laser sealed and welded is 30mm×30mm, and the inner cavity volume is about 3.4cm 3 , the oxygen-free copper shell includes electroplated nickel, gold oxygen-free copper shell and electroplated nickel, gold oxygen-free copper cover plate, the welding joint adopts the method of locking the bottom self-centering joint, specifically as figure 1 As shown, the thickness of the cover plate is 1mm, and the fit gap between the shell and the cover plate is 0.08mm.

[0041] The laser sealing and welding method for the above-mentioned oxygen-free copper shell comprises the following steps:

[0042] (1) Cleaning: Soak the oxygen-free copper shell with methanol and isopropanol in sequence. After soaking, wipe the inside and outside of the oxygen-free copper shell with dust-free paper to remove oil stains on the surface of the shell, and then use nitrogen gas (of course, it can also be cleaned). is other protective gas) to dry th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com