Solid methionine hydroxy analogue calcium salt compound with antibacterial and acidizing properties and preparation method of solid methionine hydroxy analogue calcium salt compound

A technology of methionine hydroxyl group and liquid methionine, which is applied in the field of solid methionine hydroxyl analog calcium salt complex and its preparation, and can solve the problems of complicated process, high viscosity, difficult control of reaction speed, pressure and temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

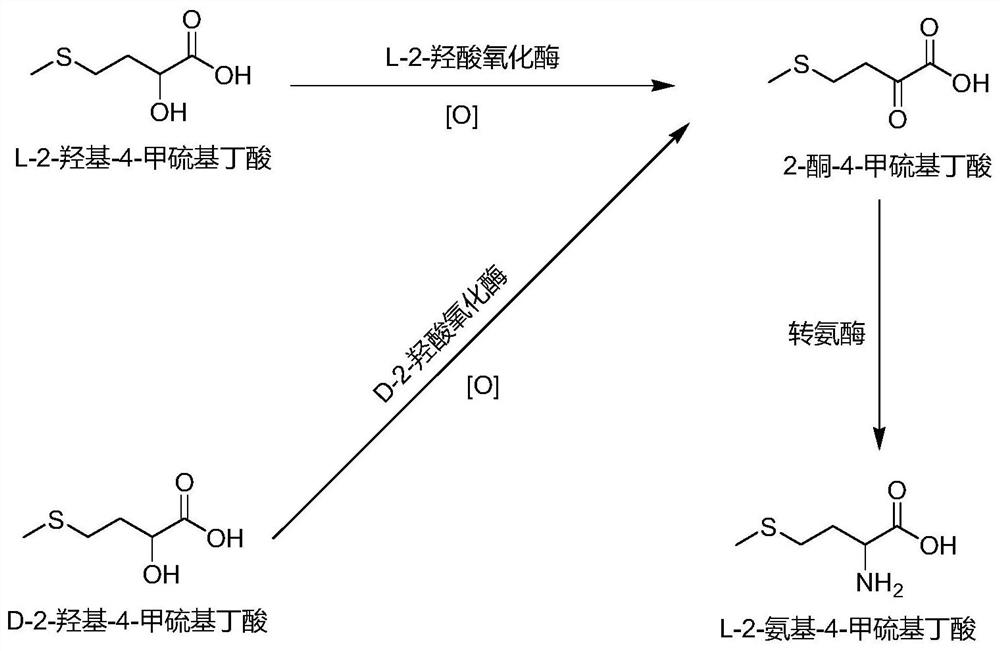

Method used

Image

Examples

Embodiment 1

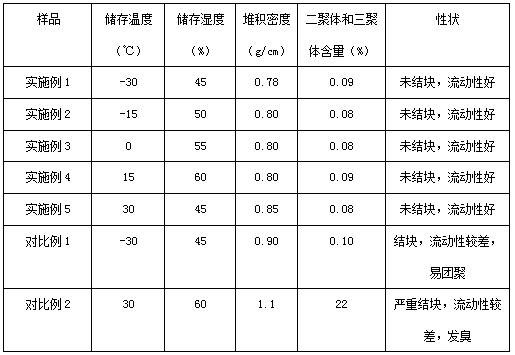

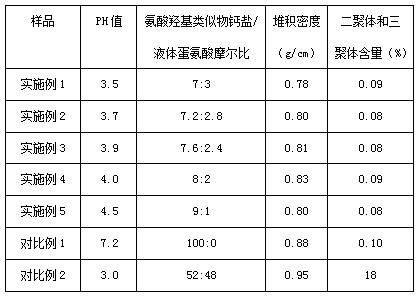

[0040] Add 170.45kg of 88wt% methionine hydroxy analogs to a 1000L enamel reaction kettle, then add 329.55kg of water, dilute to an aqueous solution with a mass percentage of methionine hydroxy analogs of 30wt%, raise the temperature to 40°C, and stir for 30 minutes. Then add 19.80kg of calcium oxide powder with a mass percentage of 99.0wt% to the aqueous solution of methionine hydroxyl analogs, control the neutralization reaction temperature at about 80°C, and obtain a light yellow transparent liquid after adding the powdered calcium oxide. The mass percent content of methionine hydroxyl analogs in the medium is 28.86wt%, and the pH is 3.5.

[0041] The obtained transparent liquid was spray-dried, and the spray-drying temperature was 110°C. After spray-drying, 164.20 kg of a powdery white solid, methionine hydroxyl analog calcium salt complex, was obtained, and the bulk density of the complex was 0.78 g / cm, wherein the mass percentage of methionine hydroxyl analogue is 91.0w...

Embodiment 2

[0043] Add 170.45kg of 88wt% methionine hydroxy analogs to a 1000L enamel reaction kettle, then add 329.55kg of water, dilute to an aqueous solution with a mass percentage of methionine hydroxy analogs of 30wt%, raise the temperature to 40°C, and stir for 30 minutes. Then add 20.36kg of calcium oxide powder with a mass percentage of 99.0wt% to the aqueous solution of methionine hydroxyl analogs, control the neutralization reaction temperature at about 85°C, and obtain a light yellow transparent liquid after adding the powdered calcium oxide. The mass percent content of methionine hydroxyl analogs in the medium is 28.83wt%, and the pH is 3.7.

[0044] Spray-dry the obtained transparent liquid at a temperature of 110°C. After drying, 164.40 kg of a powdery white solid, methionine hydroxyl analog calcium salt complex, is obtained. The bulk density of this complex is 0.80 g / cm, and the methionine hydroxyl analog The mass percent composition of substance is 91.0wt%, the mass percen...

Embodiment 3

[0046] Add 170.45kg of 88wt% methionine hydroxy analogs to a 1000L enamel reaction kettle, then add 258.12kg of water, dilute to an aqueous solution with a mass percentage of methionine hydroxy analogs of 35wt%, raise the temperature to 40°C, and stir for 40 minutes. Then add 21.50kg of calcium oxide powder with a mass percentage of 99.0wt% to the aqueous solution of methionine hydroxyl analogs, control the neutralization reaction temperature at about 85°C, and obtain a light yellow transparent liquid after adding the powdered calcium oxide. Sampling analysis was carried out, and it was detected that the mass percentage of methionine hydroxyl analogs was 33.33 wt%, and the pH of the aqueous solution was 3.9.

[0047] Spray-dry the obtained transparent liquid at a temperature of 110° C. After spray-drying, 166.0 kg of a powdery white solid that is a calcium salt complex of methionine hydroxy analogs is obtained, wherein the mass percentage of methionine hydroxy analogs is 90.36 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com