Microwave chemical method for complete extraction of fluorine and rare earth in bastnaesite concentrate

A technology of microwave chemistry and cerium fluoride, which is applied in the field of microwave chemistry for fully extracting fluorine and rare earth from bastnaesite concentrate, can solve the problems of pollution, dangerous solid waste, difficult separation of fluorine and rare earth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

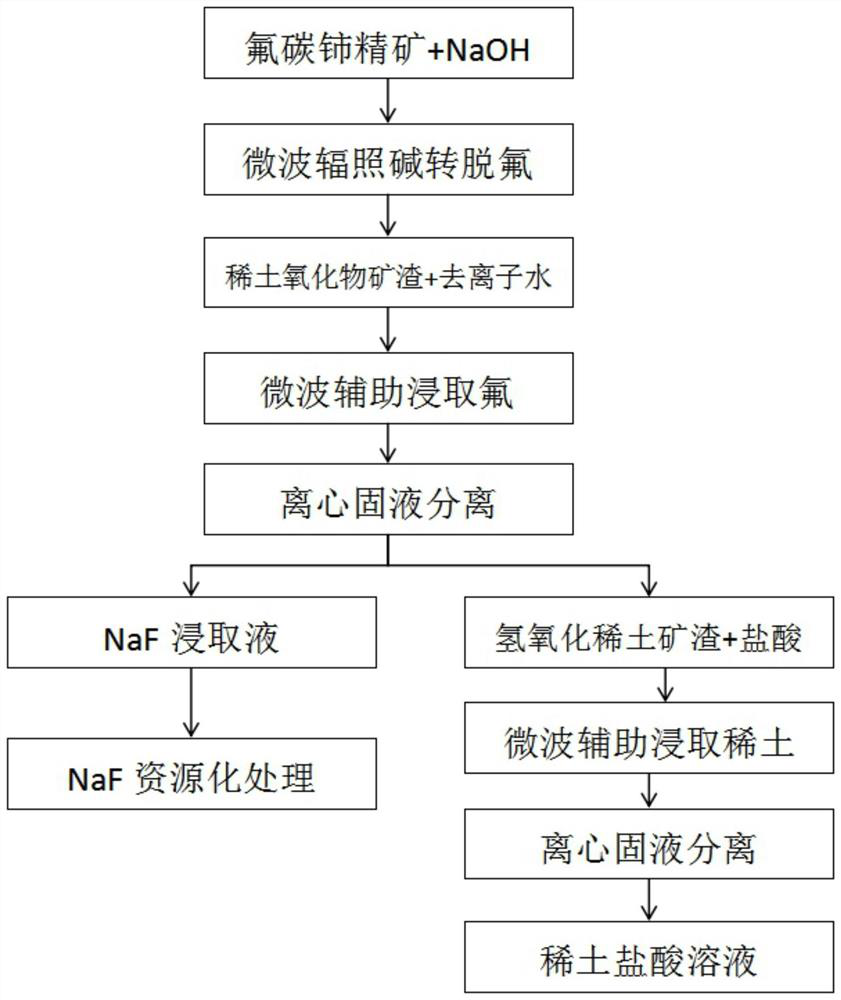

[0024] The bastnaesite concentrate used in the present invention contains 20-65.2% of rare earth oxides (REO), 3.0-11.0% of fluorine, and a particle size of ≤150 μm. According to figure 1 As shown, this embodiment provides a microwave chemical method for fully extracting fluorine and rare earths in bastnaesite concentrate, comprising the following steps:

[0025] Step 1. Alkali defluorination of bastnaesite by microwave irradiation, adding bastnaesite concentrate into a 50ml corundum crucible, and then adding sodium hydroxide evenly according to the mass ratio of bastnaesite concentrate to sodium hydroxide at 25:12 Mix and irradiate with the optimum microwave power of 700W for 5 minutes to fully defluorinate the bastnaesite concentrate by alkali conversion, so that the fluorine and rare earth in the bastnaesite concentrate can be converted into NaF and REmOn. The microwave reactor is the model "Midea EM7KCGW3- NR" transformed;

[0026] Step 2. Microwave-assisted leaching of f...

Embodiment 2

[0036] according to figure 1 As shown, this embodiment provides a microwave chemical method for fully extracting fluorine and rare earths in bastnaesite concentrate, comprising the following steps:

[0037] Step 1. Alkali defluorination of bastnaesite by microwave irradiation, adding bastnaesite concentrate into a 50ml corundum crucible, and then adding sodium hydroxide evenly according to the mass ratio of bastnaesite concentrate to sodium hydroxide at 25:12 Mix and irradiate with the optimum microwave power of 560W for 6 minutes to fully defluorinate the bastnaesite concentrate by alkali conversion, so that the fluorine and rare earth in the bastnaesite concentrate can be converted into NaF and REmOn. The microwave reactor is a model of "Midea EM7KCGW3- NR" transformed;

[0038] Step 2. Microwave-assisted leaching of fluorine, grinding the slag converted to alkali in step 1 and adding deionized water, the liquid-solid ratio is 6:1, and leaching for 6 minutes at the optimum ...

Embodiment 3

[0042] according to figure 1 As shown, this embodiment provides a microwave chemical method for fully extracting fluorine and rare earths in bastnaesite concentrate, comprising the following steps:

[0043] Step 1. Alkali defluorination of bastnaesite by microwave irradiation, adding bastnaesite concentrate into a 50ml corundum crucible, and then adding sodium hydroxide evenly according to the mass ratio of bastnaesite concentrate to sodium hydroxide at 25:12 Mix and irradiate with the optimum microwave power of 210W for 6 minutes to fully defluorinate the bastnaesite concentrate by alkali conversion, so that the fluorine and rare earth in the bastnaesite concentrate can be converted into NaF and REmOn. The microwave reactor is a model of "Midea EM7KCGW3- NR" transformed;

[0044] Step 2. Microwave-assisted leaching of fluorine, grinding the slag converted to alkali in step 1 and adding deionized water, the liquid-solid ratio is 6:1, and leaching for 6 minutes at the optimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com