Preparation method of room-temperature magnesium-based thermoelectric material and product

A thermoelectric material and room temperature technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device junction lead-out materials, etc., can solve the problems of easy introduction of impurities, unfavorable control of sample composition content, and safety accidents easily caused by raw material fine powder ball milling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of room temperature magnesium-based thermoelectric materials

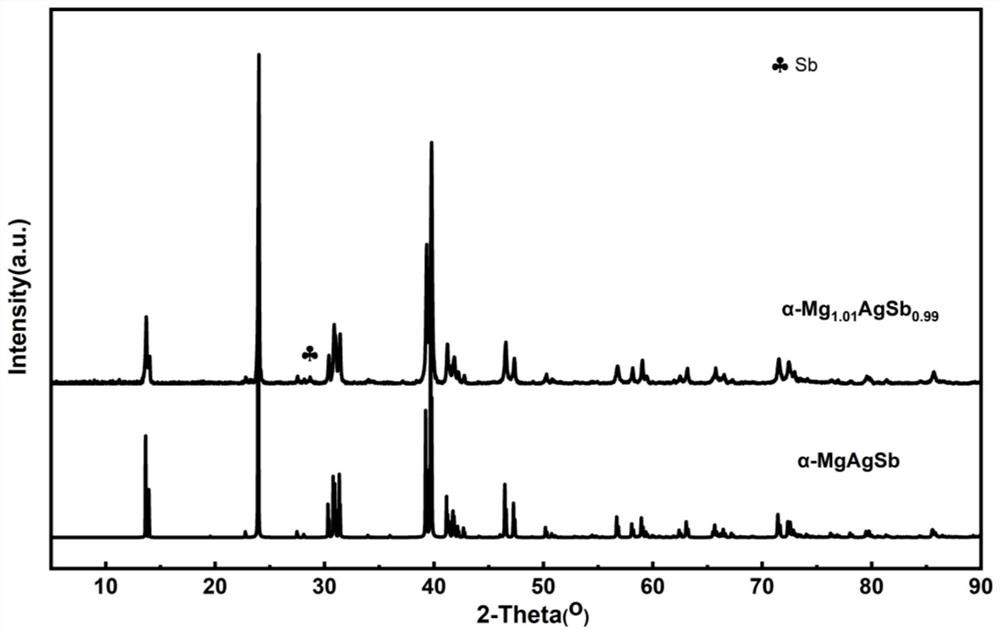

[0032]Mg powder with a purity of not less than 99.9%, Sb powder with a purity of not less than 99.999%, and Ag powder with a purity of not less than 99.99% are classified as α-Mg 1.01 AgSb 0.99 The stoichiometric ratio of each atom in the gas is weighed, and the Mg powder, Sb powder and Ag powder are sequentially loaded into the graphite mold, and then the graphite mold is placed in the cavity of the discharge plasma instrument, and the discharge plasma instrument is started after vacuuming to 10Pa. First heat up to 600°C at a rate of 100°C / min, then to 700°C at a rate of 50°C / min, to 800°C at a rate of 30°C / min, and finally to 950°C at a rate of 20°C / min After holding the heat for 30 minutes, continue vacuuming during the period, and apply a pressure of 20 MPa on the graphite mold, and then cool down to 600°C to obtain a room temperature magnesium-based thermoelectric material precursor, take t...

Embodiment 2

[0036] Preparation of room temperature magnesium-based thermoelectric materials

[0037] Mg powder with a purity of not less than 99.9%, Sb powder with a purity of not less than 99.999%, and Ag powder with a purity of not less than 99.99% are classified as α-Mg 0.99 AgSb 0.97 The stoichiometric ratio of each atom in the gas is weighed, and the Mg powder, Sb powder and Ag powder are sequentially loaded into the graphite mold, and then the graphite mold is placed in the cavity of the discharge plasma instrument, and the discharge plasma instrument is started after vacuuming to 8Pa. First raise the temperature to 600°C at a rate of 80°C / min, then raise the temperature to 800°C at a rate of 50°C / min, and finally raise the temperature to 900°C at a rate of 20°C / min. A pressure of 30MPa was applied to the mold, and then the temperature was lowered to 400°C to obtain a magnesium-based thermoelectric material precursor at room temperature. The precursor was taken out and put into a g...

Embodiment 3

[0039] Preparation of room temperature magnesium-based thermoelectric materials

[0040] Mg powder with a purity of not less than 99.9%, Sb powder with a purity of not less than 99.999%, and Ag powder with a purity of not less than 99.99% are classified as α-Mg 0.98 AgSb 0.95 The stoichiometric ratio of each atom in the gas is weighed, and the Mg powder, Sb powder and Ag powder are sequentially loaded into the graphite mold, and then the graphite mold is placed in the cavity of the discharge plasma instrument, and the discharge plasma instrument is started after vacuuming to 5Pa. First raise the temperature to 600°C at a rate of 60°C / min, then raise the temperature to 800°C at a rate of 30°C / min, and finally raise the temperature to 1000°C at a rate of 20°C / min. A pressure of 40MPa is applied to the mold, and then the temperature is lowered to 500°C to obtain a room temperature magnesium-based thermoelectric material precursor. The precursor is taken out and put into a graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com