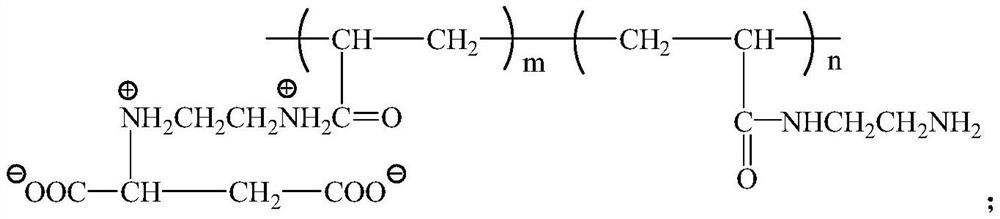

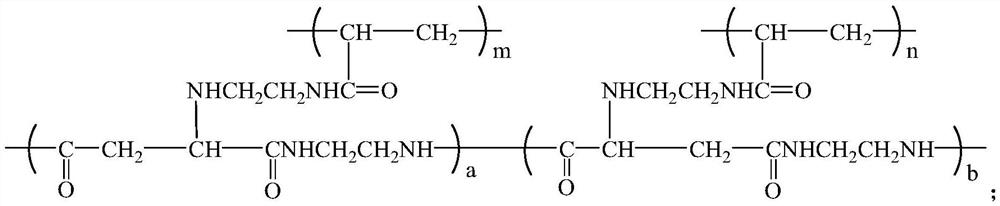

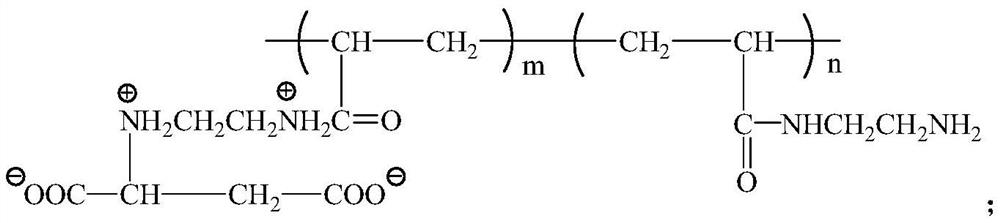

Amphiphilic polyamine high-molecular polymerization type viscose cotton blending leveling agent and preparation method thereof

A leveling agent and polymerized technology, applied in the field of amphoteric polyamine polymer polymer viscose-cotton blended leveling agent and preparation, can solve the problem that the reactive leveling agent cannot meet the requirements of the process, and reduce high salt The effect of high alkali discharge and improving fixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 85 parts of acryloyl ethylenediamine, 0.5 parts of initiator, 13 parts of maleic anhydride, 1 part of affinity addition catalyst, 4 parts of alkali agent, 6 parts of ethylenediamine, 0.5 parts of amidation reaction catalyst, of which nucleophilic addition catalyst It is 4-dimethylaminopyridine, the amide condensation catalyst is ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, the initiator is ammonium persulfate, the alkali agent is sodium hydroxide, and the acid agent For hydrochloric acid.

[0043] (1) Synthesis of copolymers of acryloyl ethylenediamine and propylene first ethylenediamine succinic acid

[0044] a. Add acryloylethylenediamine and deionized water into a four-necked flask equipped with a thermometer, a water separator and a condensing reflux device, and fill with nitrogen to remove the air.

[0045] b. Turn on the stirring device, slowly raise the temperature to 70-110°C, start to slowly add the ammonium persulfate aqueous solution dropwise, a...

Embodiment 2

[0058] Different from the above case, the main components of this scheme are 95 parts of acryloyl ethylenediamine, 0.5 parts of initiator, 20 parts of maleic anhydride, 2 parts of affinity addition catalyst, 5 parts of alkali agent, 8 parts of ethylenediamine, amide 0.5 part of chemical reaction catalyst. The nucleophilic addition catalyst is 4-dimethylaminopyridine, the amide condensation catalyst is ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, and the initiator potassium persulfate , the alkaline agent is sodium carbonate, and the acid agent is hydrochloric acid.

[0059] Compounding of Viscose Cotton Leveling Agent

[0060] Compound the acryloyl ethylenediamine and propylene first ethylenediamine succinic acid copolymer, polyacryloyl ethylenediamine succinic acid and ethylenediamine polycondensate prepared by the above method with deionized water, according to 25%, 25% , 50% for compounding, fully stir evenly at 60-80°C, then cool down and filter to discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com