Graphite-based composite bipolar plate for fuel cell and preparation method thereof

A fuel cell and graphite-based technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high production cost of pure graphite bipolar plates, inability to reduce the thickness of graphite plates, and low volume specific power density, etc., and achieve excellent Dimensional stability, improved volumetric power density, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

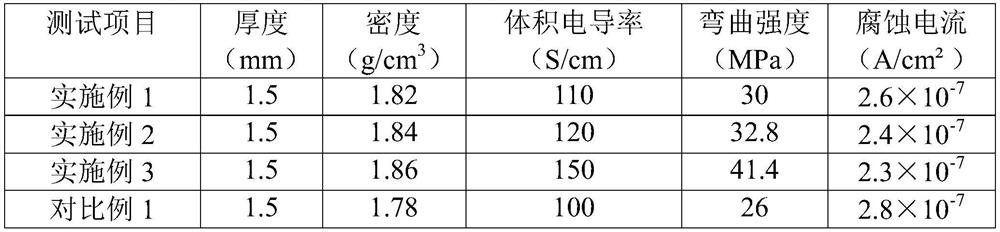

Embodiment 1

[0028] A method for preparing a graphite-based composite bipolar plate for a fuel cell, comprising the following steps:

[0029] Preparation of Carbon Nanotubes Modified by Carboxylation Reaction

[0030] Put 30g of multi-walled carbon nanotubes and 1000mL of nitric acid into a four-necked beaker, carry out acid treatment at 130°C for 10 hours, remove the acid-treated carbon nanotubes from the four-necked beaker, and put them into a vacuum filtration equipment for use Tetrahydrofuran was filtered and washed with suction. After cleaning, dry to constant weight in a vacuum dryer at 100° C. to obtain carbon nanotubes modified by carboxylation reaction, hereinafter referred to as carboxylated carbon nanotubes.

[0031] Fabrication of graphite-based composite bipolar plates

[0032] (1) 300g bisphenol A type epoxy methacrylate vinyl ester resin, polystyrene resin (low shrinkage agent) diluted with 15g styrene, 15g styrene monomer, 3g free radical initiator benzene peroxide tert-...

Embodiment 2

[0036] A method for preparing a graphite-based composite bipolar plate for a fuel cell, comprising the following steps:

[0037] Preparation of Carbon Nanotubes Modified by Carboxylation Reaction

[0038] Put 30g of multi-walled carbon nanotubes and 1000mL of nitric acid into a four-necked beaker, carry out acid treatment at 120°C for 8 hours, remove the acid-treated carbon nanotubes from the four-necked beaker, and put them into a vacuum filtration equipment for use Tetrahydrofuran was filtered and washed with suction. After cleaning, dry to constant weight in a vacuum dryer at 100° C. to obtain carbon nanotubes modified by carboxylation reaction, hereinafter referred to as carboxylated carbon nanotubes.

[0039] Fabrication of graphite-based composite bipolar plates

[0040] (1) Polystyrene resin (low shrinkage agent) diluted with 300g glycidyl ester epoxy resin, 20g styrene, 25g styrene monomer, 8g free radical initiator tert-butyl peroxybenzoate, 20g thickening Calcium ...

Embodiment 3

[0044] A method for preparing a graphite-based composite bipolar plate for a fuel cell, comprising the following steps:

[0045] Preparation of Carbon Nanotubes Modified by Carboxylation Reaction

[0046] Put 30g of multi-walled carbon nanotubes and 1000mL of sulfuric acid into a four-necked beaker, and perform acid treatment at 100°C for 12 hours, remove the acid-treated carbon nanotubes from the four-necked beaker, and put them in a vacuum filtration equipment Suction filter and wash with tetrahydrofuran. After cleaning, dry to constant weight in a vacuum dryer at 100° C. to obtain carbon nanotubes modified by carboxylation reaction, hereinafter referred to as carboxylated carbon nanotubes.

[0047] Fabrication of graphite-based composite bipolar plates

[0048] (1) Polystyrene resin (low shrinkage agent) diluted with 300g glycidylamine epoxy resin, 25g styrene, 28g styrene monomer, 10g free radical initiator perbenzoate, 20g thickener polyisocyanate , 10g of zinc stearat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com