Preparation method of carbon oxide nanohorn/sodium alginate-silver composite antibacterial agent, antibacterial agent, antibacterial coating and antibacterial film

A composite antibacterial agent, sodium alginate technology, applied in antibacterial agent, antibacterial coating, preparation of carbon oxide nanohorn/sodium alginate-silver composite antibacterial agent, antibacterial film field, can solve the impact of application scenarios and antibacterial effect, silver Discoloration of antibacterial agents, poor adsorption capacity and other problems, to achieve the effect of promoting adhesion capacity, increasing surface area, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

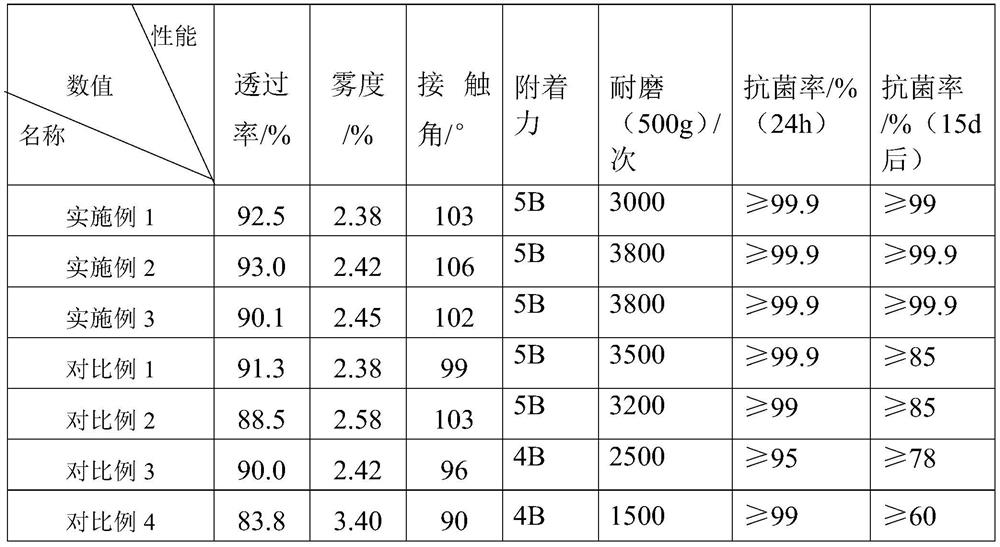

Examples

Embodiment 1

[0028] A preparation method of oxidized carbon nanohorn / sodium alginate-silver composite antibacterial agent, comprising the following steps:

[0029]1) Disperse single-walled carbon nanohorns in nitric acid solution and reflux at 120°C for 24 hours, wash with deionized water several times and then vacuum-dry to obtain oxidized single-walled carbon nanohorns; mix oxidized single-walled carbon nanohorns with deionized water, Ultrasound for 0.5h to completely disperse, and prepare a dispersion of oxidized single-walled carbon nanohorns with a concentration of 0.8mg / mL;

[0030] 2) Add 0.05 mol / L silver nitrate solution to the sodium alginate solution with a mass fraction of 0.01% while stirring, stir for 10 minutes, and continue to add the oxidized single-walled carbon nanohorn dispersion to obtain a mixed solution;

[0031] 3) The mixed solution was irradiated with ultraviolet light to obtain an oxidized single-walled carbon nanohorn / sodium alginate-silver dispersion liquid, an...

Embodiment 2

[0037] A preparation method of oxidized carbon nanohorn / sodium alginate-silver composite antibacterial agent, comprising the following steps:

[0038] 1) Disperse single-walled carbon nanohorns in nitric acid solution and reflux at 120°C for 24 hours, wash with deionized water several times and then vacuum-dry to obtain oxidized single-walled carbon nanohorns; mix oxidized single-walled carbon nanohorns with deionized water, Ultrasound for 1 hour to completely disperse, and prepare a dispersion of oxidized single-walled carbon nanohorns with a concentration of 1.2 mg / mL;

[0039] 2) Add 0.1 mol / L silver nitrate solution to the sodium alginate solution with a mass fraction of 0.2% while stirring, stir for 13 minutes, and continue to add the oxidized single-walled carbon nanohorn dispersion to obtain a mixed solution;

[0040] 3) The mixed solution was irradiated with an ultraviolet lamp to obtain an oxidized single-walled carbon nanohorn / sodium alginate-silver dispersion liquid...

Embodiment 3

[0046] A preparation method of oxidized carbon nanohorn / sodium alginate-silver composite antibacterial agent, comprising the following steps:

[0047] 1) Disperse single-walled carbon nanohorns in nitric acid solution and reflux at 120°C for 24 hours; ultrasonicate for 2 hours, wash with deionized water several times, and then vacuum-dry to obtain oxidized single-walled carbon nanohorns; mix oxidized single-walled carbon nanohorns with deionized Water was mixed in proportion, ultrasonically dispersed for 0.5h to make it completely dispersed, and a dispersion of oxidized single-walled carbon nanohorns with a concentration of 2.5mg / mL was prepared;

[0048] 2) Add 0.21 mol / L silver nitrate solution to the sodium alginate solution with a mass fraction of 0.5%, stir for 20 minutes, and continue to add the oxidized single-walled carbon nanohorn dispersion to obtain a mixed solution;

[0049] 3) The mixed solution was irradiated with an ultraviolet lamp to obtain an oxidized single-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com