A kind of PCE composite seed type early strength agent and its preparation method and application

A technology of composite crystal and early strength agent, applied in the field of concrete admixtures, can solve the problems of high durability risk, poor early strength effect and high material cost of early strength agent, achieve simple and convenient equipment operation, reduce synthesis cost, grind Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

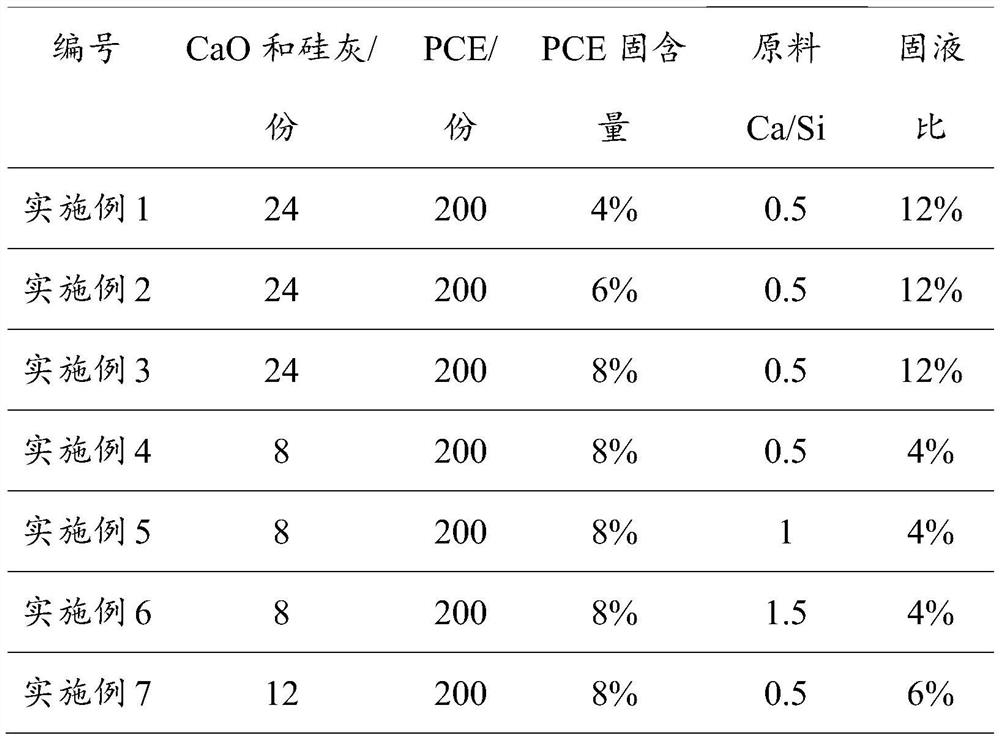

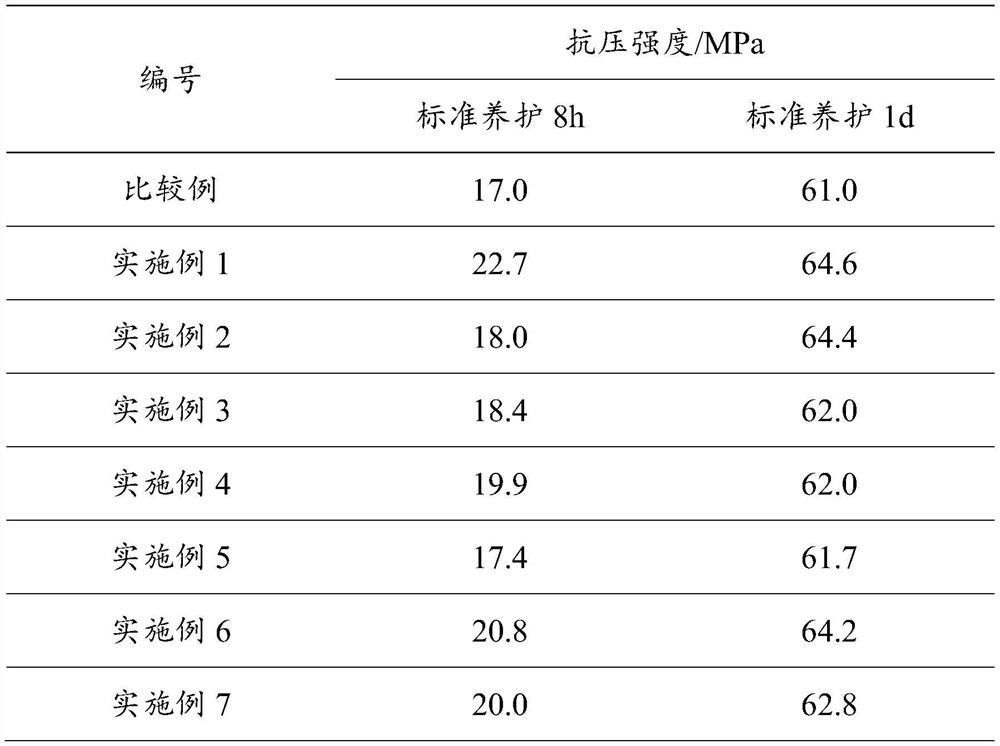

Embodiment 1

[0040] (1) Get 16 parts by weight of PCE mother liquor, add 184 parts by weight of deionized water to obtain 200 parts by weight of PCE with a solid content of 4%, which is denoted as 4%-PCE;

[0041] (2) Get 24 parts by weight to analyze pure calcium oxide and silica fume powder. Silica fume is processed through drying in advance. (the ratio of calcium oxide and silica fume total mass and 4%-PCE total mass) is 12%;

[0042] (3) Pour the weighed calcium oxide and silica fume into the grinding cylinder of the sand mill, then add 4%-PCE and 700g of zirconia grinding media with a particle size of 0.2mm in sequence, and immediately put the grinding cylinder into the sand mill In the machine, wet ultra-fine grinding is started after the cooling circulating water is connected, the speed of the sand mill is set to 2000rpm, and the average particle size of the suspension is ground to less than 300nm, and the suspension is ultrasonicated for 30 minutes to obtain the PCE composite seed ...

Embodiment 2

[0047] (1) Get 24 parts by weight of PCE mother liquor, add 176 parts by weight of deionized water to obtain 200 parts by weight of PCE with a solid content of 6%, denoted as 6%-PCE;

[0048] (2) Get 24 parts by weight to analyze pure calcium oxide and silica fume powder. Silica fume is processed through drying in advance. 12%;

[0049] (3) Pour the weighed calcium oxide and silica fume into the grinding barrel of the sand mill, then add 6%-PCE and 700g of zirconia grinding media with a particle size of 0.2mm in sequence, and immediately put the grinding barrel into the sand mill In the machine, wet ultra-fine grinding is started after the cooling circulating water is connected, the speed of the sand mill is set to 2000rpm, and the average particle size of the suspension is ground to less than 300nm, and the suspension is ultrasonicated for 30 minutes to obtain the PCE composite seed crystal. Early strength agent, wherein the rated power of the ultrasonic equipment is 600 wat...

Embodiment 3

[0054] (1) Get 32 parts by weight of the PCE mother liquor, add 168 parts by weight of deionized water to obtain 200 parts by weight of PCE with a solid content of 8%, which is denoted as 8%-PCE;

[0055] (2) Get 24 parts by weight to analyze pure calcium oxide and silica fume powder. Silica fume is processed through drying in advance. 12%;

[0056] (3) Pour the weighed calcium oxide and silica fume into the grinding barrel of the sand mill, then add 8%-PCE and 700g of zirconia grinding media with a particle size of 0.2mm in sequence, and immediately put the grinding barrel into the sand mill In the machine, wet ultra-fine grinding is started after the cooling circulating water is connected, the speed of the sand mill is set to 2000rpm, and the average particle size of the suspension is ground to less than 300nm, and the suspension is ultrasonicated for 30 minutes to obtain the PCE composite seed crystal. Early strength agent, wherein the rated power of the ultrasonic equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com