Collagen purification method

A collagen and purification method technology, applied in peptide preparation methods, chemical instruments and methods, animal/human proteins, etc., can solve the problems of collagen yield and purity not meeting the requirements, low risk, etc., to improve the yield and purity, increase the amount of precipitation, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

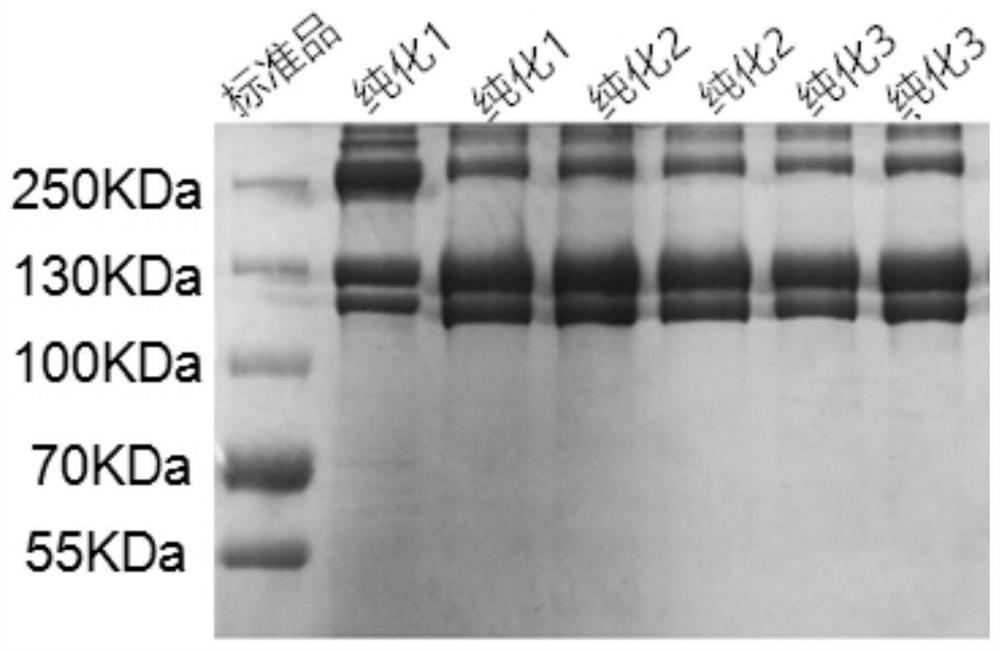

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of collagen purification method

[0051] Specifically include the following steps:

[0052] (1) Take the crude collagen extract (210L, containing about 400g of collagen), dilute it with water, add acetic acid to adjust the pH value to 2.5, add diatomaceous earth (2.1kg) and biological flocculant ( 0.7kg), stirred for 30min and adsorbed, followed by plate and frame filtration to obtain mixed solution A;

[0053] (2) Add an equal volume to the mixed solution A and the volume ratio is 5:1, the mass fraction is 15% ammonium chloride and the mass fraction is 30% ammonium sulfate mixed solution to carry out salting out for 2h to obtain solid B, and the solid B After reconstitution, the obtained reconstituted solution is first filtered with a 5-micron filter membrane, the obtained filtrate a is then filtered with a 3-micron filter membrane, and the obtained filtrate b is then filtered with a 0.45-micron filter membrane to obtain a mixture C;

[0054] (3) ...

Embodiment 2

[0056] Embodiment 2 A kind of collagen purification method

[0057] Specifically include the following steps:

[0058] (1) Take the crude collagen extract (210L, containing about 400g of collagen), dilute it with water, add acetic acid to adjust the pH value to 3.5, add diatomaceous earth (8.4kg) and biological flocculant ( 1.4kg), plate and frame filtration was carried out after adsorption, and then 0.1 μm membrane filtration was carried out to obtain the mixed solution A;

[0059] (2) Add an equal volume of ammonium chloride with a volume ratio of 10:1 and a mixed solution of ammonium sulfate with a mass fraction of 25% and 40% ammonium sulfate in the mixed solution A for salting out to obtain a solid B, and redissolve the solid B Finally, the obtained complex solution is first filtered with a 5-micron filter membrane, the obtained filtrate a is then filtered with a 3-micron filter membrane, and the obtained filtrate b is then filtered with a 0.45-micron filter membrane to ...

Embodiment 3

[0062] Embodiment 3 A kind of collagen purification method

[0063] Specifically include the following steps:

[0064] (1) Take the crude collagen extract (210L, containing about 400g of collagen), dilute it with water, add acetic acid to adjust the pH value to 3.0, add diatomaceous earth (6.3kg) and biological flocculant ( 1.26kg), after adsorption, perform plate and frame filtration, and then perform 0.1 μm membrane filtration to obtain mixed solution A;

[0065] (2) adding volume ratio to mixed solution A is that 8:1 mass fraction is 20% ammonium chloride and mass fraction is the ammonium sulfate mixed solution of 35% to obtain solid B after salting out, after solid B is redissolved, The obtained complex solution is first filtered with a 5-micron filter membrane, the obtained filtrate a is then filtered with a 3-micron filter membrane, and the obtained filtrate b is then filtered with a 0.45-micron filter membrane to obtain a mixed solution C;

[0066] (3) The mixture C w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com