Foamed HDPE wood-plastic profile and preparation method thereof

A technology of wood-plastic profile and wood powder, which is applied in the field of foamed HDPE wood-plastic profile and its preparation, which can solve the problems of uneven appearance, easy to be corroded by microorganisms, and insufficient product strength, so as to improve compatibility and interface bonding Strength, good biocompatibility and antibacterial activity, smooth and bright appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

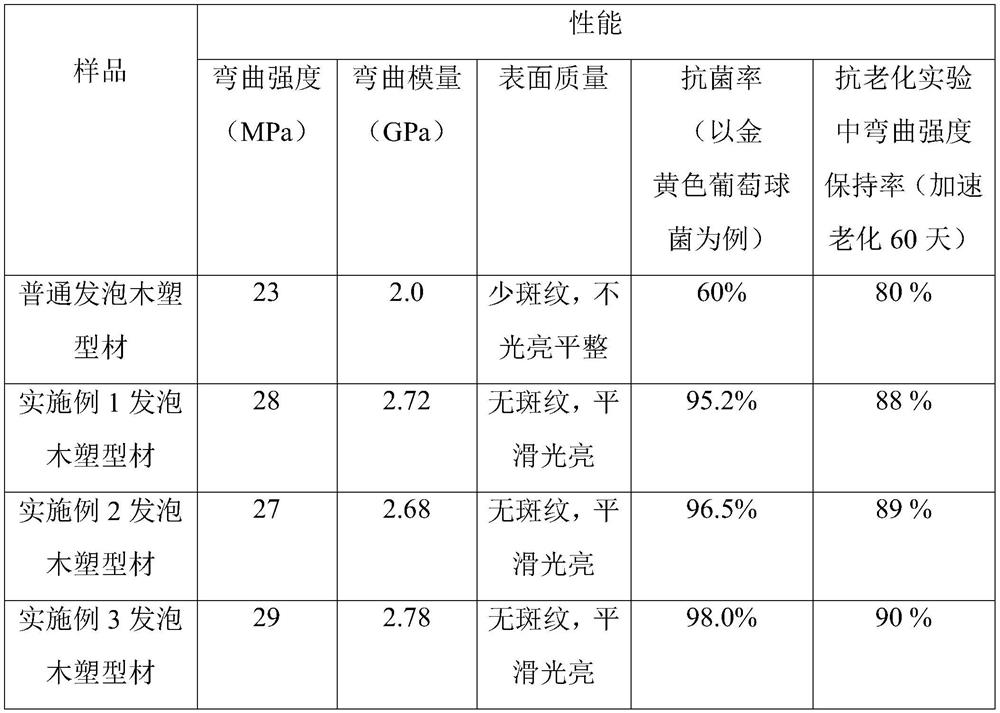

Examples

Embodiment 1

[0026] A kind of foamed HDPE wood-plastic profile of the present embodiment, comprises the raw material of following parts by weight: 20 parts of HDPE substrates, 8 parts of POE powders, 30 parts of wood powders of chitosan-nano-silver composite antibacterial agent pretreatment, particle diameter 2 parts of 100nm nano-calcium oxide powder, 2 parts of long-chain alkyl and polyether co-modified silicone oil, 0.5 part of zinc stecholate, 0.5 part of AC foaming agent, and 0.5 part of BASF UV-234 anti-aging agent.

[0027] The preparation method of the foamed HDPE wood-plastic profile is:

[0028] (1) prepare antibacterial agent: chitosan is dissolved in the acetic acid solution of 0.2wt%, makes chitosan acetic acid solution; Add the silver nitrate aqueous solution of 0.02mol / L in chitosan acetic acid solution, chitosan acetic acid The volume ratio of the solution to the silver nitrate aqueous solution is controlled at 80:1; after reacting the mixed solution on a 600r / min magnetic ...

Embodiment 2

[0034] A kind of foamed HDPE wood-plastic profile of the present embodiment, comprises the raw material of following parts by weight: 50 parts of HDPE substrates, 13 parts of POE powders, 60 parts of wood powders of chitosan-nano-silver composite antibacterial agent pretreatment, particle diameter 4 parts of 500nm nano calcium oxide powder, 4 parts of long-chain alkyl and polyether co-modified silicone oil, 5 parts of ethylene bis fatty acid amide, 5 parts of AC foaming agent, 0.8 part of BASF UV-234 anti-aging agent.

[0035] The preparation method of the foamed HDPE wood-plastic profile is:

[0036](1) prepare antibacterial agent: chitosan is dissolved in the acetic acid solution of 2wt%, makes chitosan acetic acid solution; Add the silver nitrate aqueous solution of 0.2mol / L in chitosan acetic acid solution, chitosan acetic acid solution The volume ratio with the silver nitrate aqueous solution is controlled at 100:1; after reacting the mixed solution on a 900r / min magnetic...

Embodiment 3

[0042] A kind of foamed HDPE wood-plastic profile of the present embodiment comprises the raw material of following parts by weight: 30 parts of HDPE substrates, 10 parts of POE powders, 45 parts of wood powders of chitosan-nano-silver composite antibacterial agent pretreatment, particle diameter 3 parts of 300nm nano-calcium oxide powder, 3 parts of long-chain alkyl and polyether co-modified silicone oil, 3 parts of 3-polyester wax, 3 parts of AC foaming agent, 0.7 part of BASF UV-234 anti-aging agent.

[0043] The preparation method of the foamed HDPE wood-plastic profile is:

[0044] (1) prepare antibacterial agent: chitosan is dissolved in the acetic acid solution of 1wt%, makes chitosan acetic acid solution; Add the silver nitrate aqueous solution of 0.1mol / L in chitosan acetic acid solution, chitosan acetic acid solution The volume ratio with the silver nitrate aqueous solution is controlled at 90:1; after reacting the mixed solution on an 800r / min magnetic stirrer for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com