Electret master batch as well as preparation method and application thereof

A kind of masterbatch and electret technology, which is applied in rayon manufacturing, textile and paper making, single-component polyolefin artificial filament, etc. It can solve the problems of virus infection, block virus passage, and lack of filtration effect, and achieve high filtration efficiency. , low breathing resistance, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

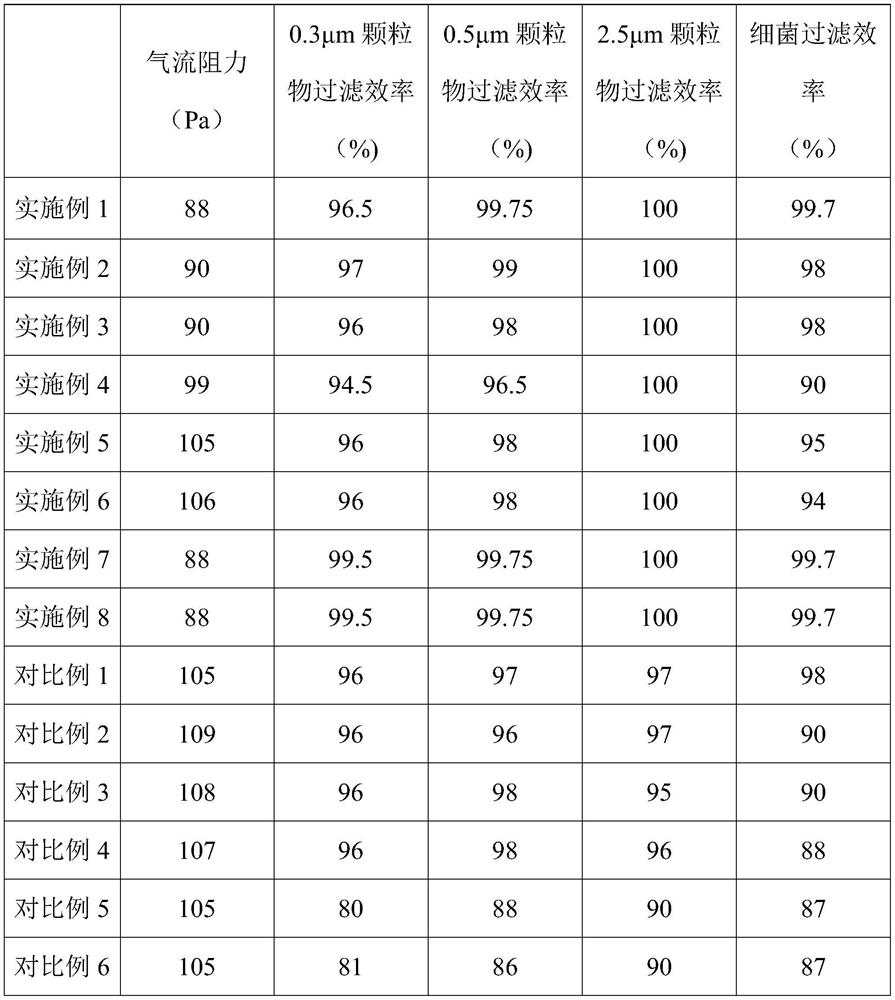

Examples

Embodiment 1

[0066] The present embodiment provides a kind of electret masterbatch, the preparation raw material of described electret masterbatch comprises following components according to mass percentage: polypropylene resin 60% (the number average molecular weight is 18000g / mol), antimicrobial agent 4% (ten Hexaalkyltrimethylammonium bromide), electret 10% (nano barium titanate), dispersant 15% (magnesium stearate), nucleating agent 6% (benzylidene sorbitol), coupling agent 0.6% (titanate coupling agent, purchased from Green Chemicals, brand TMC980), 3% compatibilizer (maleic anhydride grafted polypropylene, number average molecular weight is 23000g / mol), antioxidant 0.25% (purchased In Lianlong, the trade mark is antioxidant 168), light stabilizer 1.15% (purchased in the market Lianlong, the trade mark is UV944).

[0067] The preparation method of above-mentioned electret masterbatch is as follows:

[0068] (1) Raise the temperature of the mixer to 105°C for the first time, add elect...

Embodiment 2

[0075] This embodiment provides a kind of electret masterbatch, the preparation raw material of described electret masterbatch comprises following components according to mass percentage: polypropylene resin 50% (the number average molecular weight is 18000g / mol), antibacterial agent 5% (mass percentage Dialkyldimethylammonium chloride and alkylamine oxide (such as octadecyldihydroxyethylamine oxide) in a ratio of 1:1, electret 15% (nano tourmaline powder), dispersant 13 % (zinc stearate and N,N'-ethylene bisstearamide with a mass ratio of 1:1), nucleating agent 10% (benzylidene sorbitol), coupling agent 1.0% (silane coupling agent , purchased from Green Chemicals, trade mark TMC980), compatibilizer 5.0% (polypropylene grafted with glycidyl methacrylate, number average molecular weight is 10000g / mol), antioxidant 0.5% (purchased from Lianlong, trade mark Antioxidant 1010), light stabilizer 0.5% (purchased from Rianlong, trade mark is UV944).

[0076] The preparation method of...

Embodiment 3

[0083]This embodiment provides a kind of electret masterbatch, the preparation raw material of described electret masterbatch comprises the following components according to mass percentage: polypropylene resin 76.25% (number average molecular weight is 18000g / mol), antibacterial agent 3% (beet Alkali), electret 5% (fluoropolymer, number average molecular weight 10000g / mol, purchased from Luju, trade mark is LANPOLY1001), dispersant 10% (calcium stearate), nucleating agent 3% (phosphate ester ), coupling agent 0.2% (silane coupling agent, purchased from Green Chemical Industry, trade mark is TMC-980), compatibilizer 1.0% (ethylene-octene copolymer of maleic anhydride grafting, number average molecular weight is 10000g / mol), antioxidant 0.15% (purchased from Rianron, the trade mark is antioxidant 626), light stabilizer 1.5% (purchased from Rianron, the trade mark is UV944).

[0084] The preparation method of above-mentioned electret masterbatch is as follows:

[0085] (1) Rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com