Nitrogen-doped and oxygen vacancy-modified zinc manganate nanotube array material as well as preparation method and application thereof

A technology of nanotube array and nanorod array, which is applied in the field of zinc manganate nanotube array materials and its preparation, can solve the problems of poor rate performance and cycle life, low electronic/ionic conductivity, large initial irreversible capacity, etc., and achieve The effects of high magnification, increased specific surface area, increased active sites, and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] A method for preparing nitrogen-doped and oxygen-vacancy-modified zinc manganate nanotube arrays:

[0095] (1) Preparation of flexible carbon cloth substrate:

[0096] Set the size to 4×4cm 2 The flexible carbon cloth is placed in absolute ethanol for ultrasonic treatment to obtain a cleaned flexible carbon cloth substrate;

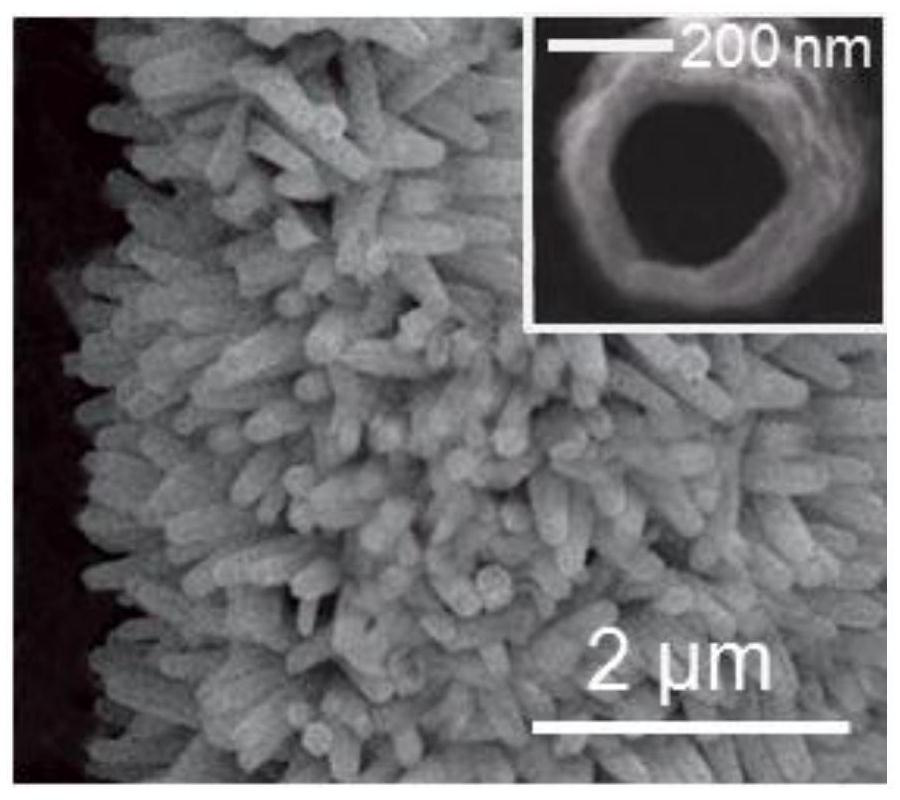

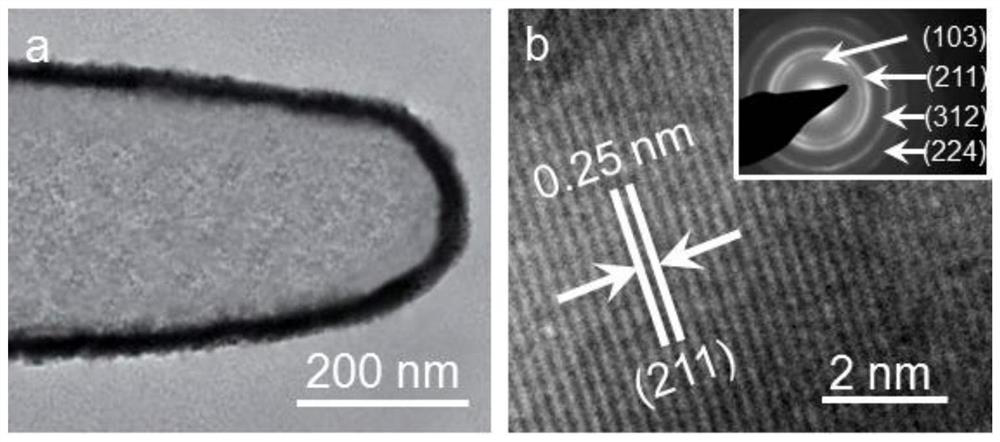

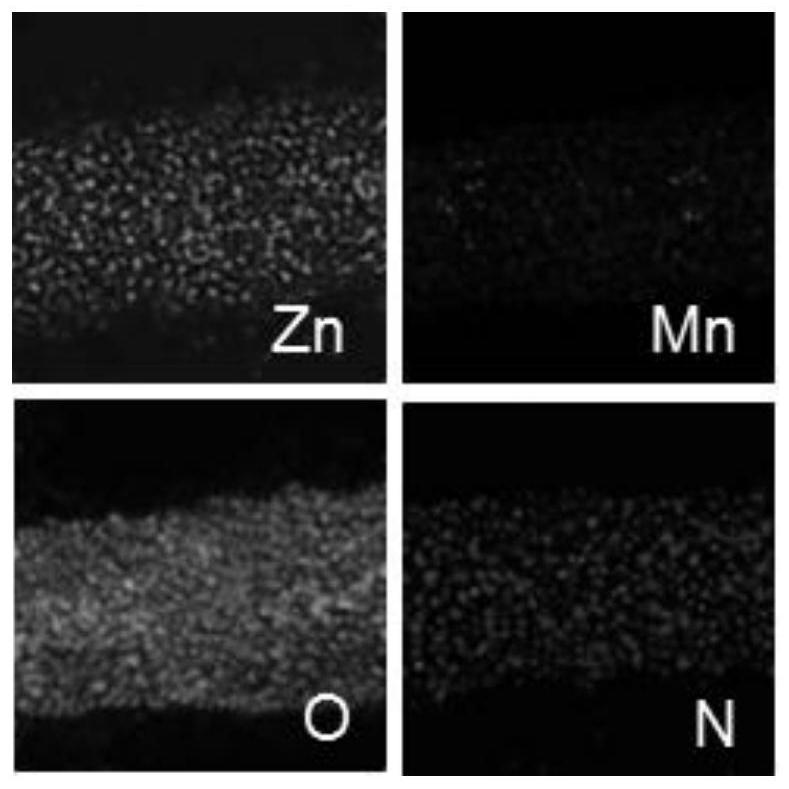

[0097] (2) Preparation of N-ZMO nanotube array material:

[0098] A. Preparation of ZnO nanorod array material: 0.1894g Zn(NO 3 ) 2 and 0.4g NH 4 NO 3 Dissolve in deionized water at room temperature and set the volume to 1000mL, and ultrasonically disperse evenly; using graphite electrode as the counter electrode and the flexible carbon cloth substrate obtained in step (1) as the working electrode, at a current density of 0.4mA cm -2 , electrodeposition reaction at 70°C for 1.5h, after natural cooling, rinse with deionized water and dry to obtain ZnO nanorod array material grown on flexible carbon cloth substrate;

[0099] B. Preparation of Zn...

Embodiment 2-5

[0105] The preparation method of embodiment 2-5 is identical with embodiment 1, and difference is that Zn(NO 3 ) 2 the mass used.

[0106] Concrete Zn(NO in the preparation method of embodiment 2-5 3 ) 2 The quality controls used are listed in Table 1.

[0107] Table 1 Zn(NO 3 ) 2 quality control

[0108]

Embodiment 6-9

[0110] The preparation method of embodiment 6-9 is the same as embodiment 1, and difference is that in step (2) A, NH 4 NO 3 the mass used.

[0111] Concrete NH in the preparation method of embodiment 2-9 4 NO 3 The quality controls used are listed in Table 2.

[0112] Table 2 NH 4 NO 3 quality control

[0113]

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com