Power source growth promoting composite medicament, preparation method, application and medicament

A compound agent and power source technology, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problem of increased sludge treatment and disposal costs, low environmental risk, dosage and transportation volume Large and other problems, to achieve the effect of improving sludge settling performance, wide application range, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

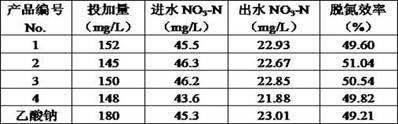

Examples

Embodiment 1

[0027] The mass percentage of each component in the obtained power source growth-promoting compound agent is: calcium acetate 2.5%, acetic acid 0.5%, sodium acetate 10%, ethanol 10%, brown sugar (or molasses) 25%, ferric chloride 0.5%, chloride Manganese 0.5%, biological enzyme 0.5%, and the rest is water.

[0028] 1. Add deionized water into the container, add a certain amount of calcium acetate into the deionized water, and stir until completely dissolved;

[0029] 2. After standing at room temperature for 1 hour, slowly add quantitative acetic acid and sodium acetate trihydrate to the above solution and stir until completely dissolved;

[0030] 3. Add a certain amount of brown sugar or waste molasses to the above mixture, and stir until completely dissolved;

[0031] 4. Add a certain amount of ferric chloride and manganese chloride to the above mixed solution, and stir until completely dissolved;

[0032] 5. Finally, add a certain amount of biological enzyme, stir for 1-2...

Embodiment 2

[0034] The mass percentage of each component in the obtained power source growth-promoting compound agent is: calcium acetate 5%, acetic acid 2%, sodium acetate 10%, ethanol 15%, brown sugar (or molasses) 30%, ferric chloride 1%, chloride Manganese 2%, biological enzyme 2%, and the rest is water.

[0035] 1. Add deionized water into the container, add a certain amount of calcium acetate into the deionized water, and stir until completely dissolved;

[0036] 2. After standing at room temperature for 1 hour, slowly add quantitative acetic acid and sodium acetate trihydrate to the above solution and stir until completely dissolved;

[0037] 3. Add a certain amount of brown sugar or waste molasses to the above mixture, and stir until completely dissolved;

[0038] 4. Add a certain amount of ferric chloride and manganese chloride to the above mixed solution, and stir until completely dissolved;

[0039] 5. Finally, add a certain amount of biological enzyme, stir for 1-2 hours to ...

Embodiment 3

[0041] The mass percentage of each component in the obtained power source growth-promoting compound agent is: calcium acetate 5%, acetic acid 1.5%, sodium acetate 15%, ethanol 10%, brown sugar (or molasses) 20%, ferric chloride 0.2%, chloride Manganese 1.5%, biological enzyme 1.5%, and the rest is water.

[0042] 1. Add deionized water into the container, add a certain amount of calcium acetate into the deionized water, and stir until completely dissolved;

[0043] 2. After standing at room temperature for 1 hour, slowly add quantitative acetic acid and sodium acetate trihydrate to the above solution and stir until completely dissolved;

[0044] 3. Add a certain amount of brown sugar or waste molasses to the above mixture, and stir until completely dissolved;

[0045] 4. Add a certain amount of ferric chloride and manganese chloride to the above mixed solution, and stir until completely dissolved;

[0046]5. Finally, add a certain amount of biological enzymes, stir for 1-2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com