A kind of method for catalyzing oxidation of pyranoside to synthesize uronic acid

A pyranoside and catalytic oxidation technology, which is applied in chemical instruments and methods, sugar compounds with non-glycosyl groups, organic chemistry, etc., can solve problems such as complex operation, high processing difficulty, human interference, etc., to simplify the reaction process, The effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

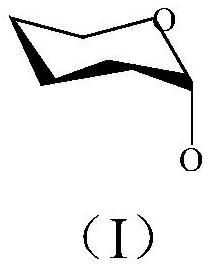

Image

Examples

Embodiment 1

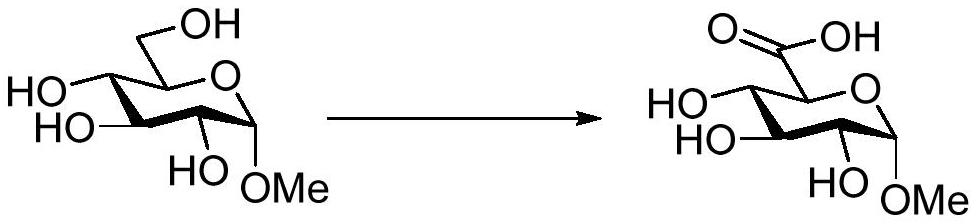

[0031] The embodiment of the present invention provides a kind of method for catalyzing oxidation methyl-α-D-glucopyranoside to obtain methyl-α-D-glucuronide, and its concrete reaction process is as follows:

[0032]

[0033] In a 50mL three-necked round bottom flask, add methyl-α-D-glucopyranoside 0.39g (2mmol), TEMPO 0.016g (0.1mmol) and water 10mL successively;

[0034] Under the condition that temperature is 0 DEG C, add calcium hypochlorite solid 0.31g (2.2mmol) in batches, feeding time is 10min, wait for feeding to end, carry out catalytic oxidation reaction, and reaction time is 4h;

[0035] After completion of the reaction, stand for layers, filter under reduced pressure, adjust the pH of the obtained filtrate to 2 with 4 mol / L HCl, concentrate under reduced pressure to remove solvent water, add 8 mL of methanol to the obtained concentrate, shake and filter to remove inorganic salts , the obtained filtrate was rotary evaporated to remove the solvent to obtain 0.388 ...

Embodiment 2

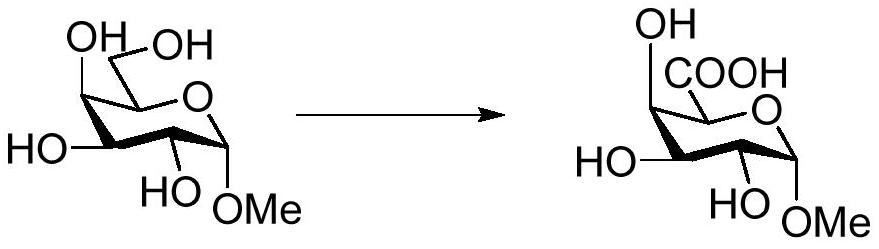

[0038] The embodiment of the present invention provides a method for catalyzing oxidation of methyl-α-D-galactopyranoside to obtain methyl-α-D-galacturonic acid, and its concrete reaction process is as follows:

[0039]

[0040]In a 50mL three-necked round-bottomed flask, add methyl-α-D-galactopyranoside 0.39g (2mmol), TEMPO 0.016g (0.1mmol) and water 40mL in turn;

[0041] Under the condition that temperature is 10 ℃, add calcium hypochlorite solid 0.43g (3mmol) in batches, feeding time is 10min, wait for feeding to end, carry out catalytic oxidation reaction, and the reaction time is 3h;

[0042] After completion of the reaction, stand for stratification, filter under reduced pressure, adjust the pH of the obtained filtrate to 3 with 3 mol / L HCl, concentrate under reduced pressure to remove solvent water, add 8 mL of ethanol to the obtained concentrate, shake and filter to remove inorganic salts , the obtained filtrate was rotary evaporated to remove the solvent to obtain...

Embodiment 3

[0045] The embodiment of the present invention provides a kind of method that catalytic oxidation methyl-α-D-mannopyranoside obtains methyl-α-D-mannopyranoic acid, and its concrete reaction process is as follows:

[0046]

[0047] In a 50mL three-necked round-bottomed flask, add methyl-α-D-mannopyranoside 0.39g (2mmol), TEMPO 0.032g (0.02mmol) and water 30mL successively;

[0048] Under the condition that temperature is 20 DEG C, add calcium hypochlorite solid 0.57g (4mmol) in batches, and the feeding time is 10min. When the feeding is finished, carry out catalytic oxidation reaction, and the reaction time is 1h;

[0049] After completion of the reaction, stand for stratification, filter under reduced pressure, adjust the pH of the obtained filtrate to 2 with 5 mol / L HCl, concentrate under reduced pressure to remove solvent water, add 8 mL of methanol to the obtained concentrate, shake and filter to remove inorganic salts , the obtained filtrate was rotary evaporated to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com