Low-temperature deblocking isocyanate curing agent and preparation method thereof

A technology of isocyanate and curing agent, which is applied in the field of isocyanate curing agent unblocked at low temperature and its preparation, can solve the problems of affecting the bonding strength of the adhesive to wood, side effects, and easy deformation, so as to achieve easy popularization, good stability, and convenience transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a low-temperature unblocked isocyanate curing agent, comprising the steps of:

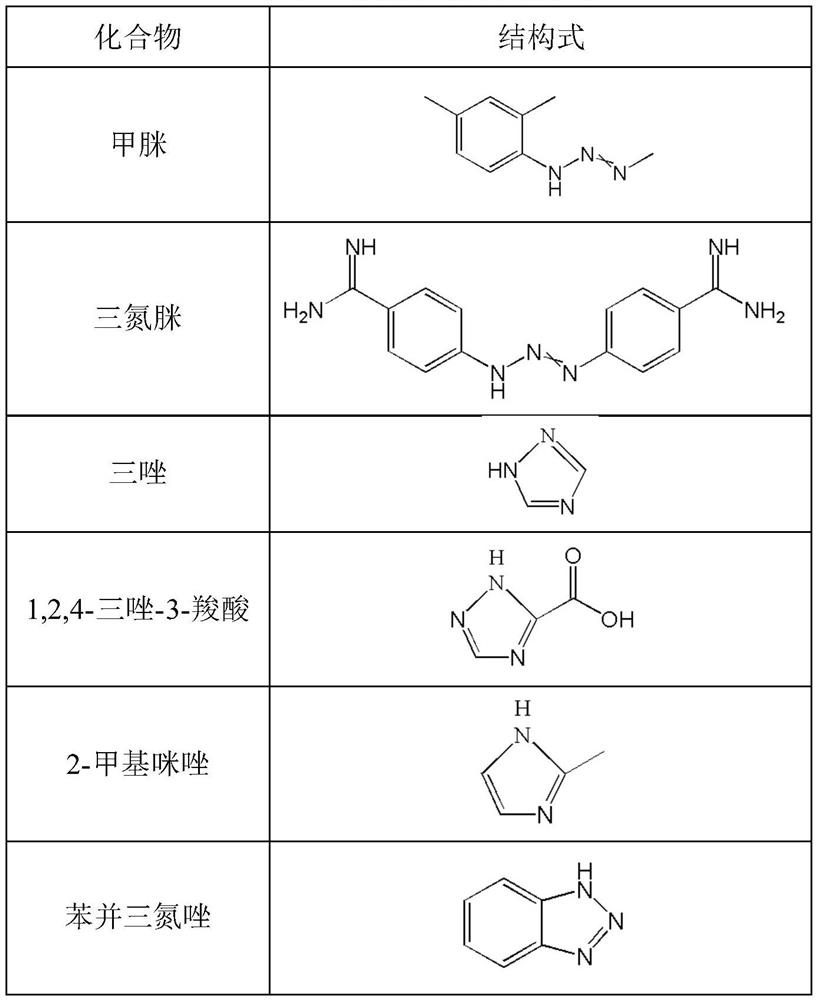

[0027] Heat 80g of HDI trimer to 50°C, add 4g of sodium bisulfite to it, and react for 2h under slow stirring; further add 3g of formamidine to it, keep the temperature at 50°C for 3h; raise the temperature of the reaction system to 60°C , add 7g of triazole, heat preservation reaction for 4h, to obtain isocyanate curing agent, recorded as sample 1.

Embodiment 2

[0029] A preparation method of a low-temperature unblocked isocyanate curing agent, comprising the steps of:

[0030] Heat 90g of HDI trimer to 60°C, add 6g of potassium bisulfite to it, and react for 3h under slow stirring; further add 7g of triazine to it, keep the temperature at 60°C for 4h; raise the temperature of the reaction system to 70 ℃, add 3g of 1,2,4-triazole-3-carboxylic acid, and keep the temperature for 5 hours to obtain the isocyanate curing agent, which is recorded as sample 2.

Embodiment 3

[0032] A preparation method of a low-temperature unblocked isocyanate curing agent, comprising the steps of:

[0033] Raise the temperature of 85g HDI trimer to 55°C, add 5g of sodium bisulfite to it, and react for 2.5h under slow stirring; further add 5g of triazine to it, keep the temperature at 55°C for 3.5h; raise the temperature of the reaction system To 65°C, add 5g of triazole, keep warm for 4.5h to obtain an isocyanate curing agent, which is recorded as sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com