Antistatic graphene latex slurry as well as process and application thereof

A graphene and antistatic technology, applied in the field of antistatic graphene latex slurry, can solve problems such as poor antistatic effect and achieve good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

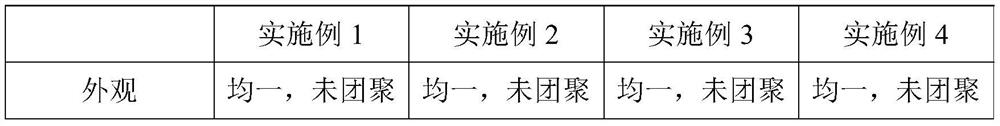

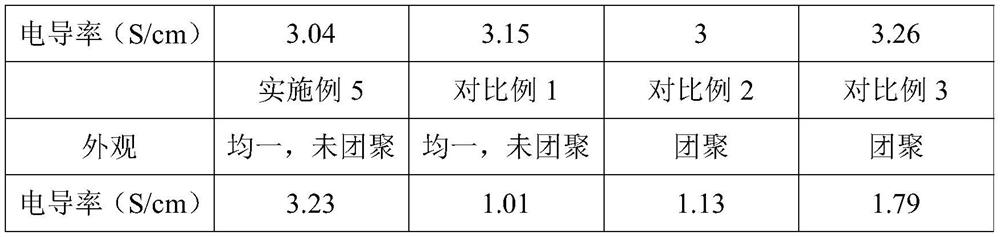

Examples

Embodiment 1

[0080] The present embodiment provides an antistatic graphene latex slurry and a preparation method thereof, wherein the antistatic graphene latex slurry includes the following components in parts by weight: 80 parts of natural latex, 3 parts of sulfur, and 4 parts of carbon nanotubes , 5 parts of functionalized graphene, 2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 3 parts of 2,6-di-tert-butyl-4-methylphenol and 15 parts of water;

[0081] The functionalized graphene includes the following raw material components in mass percentage: 10% graphene oxide, 6% sodium hydroxide, 8% octadecylamine and 76% sodium borohydride.

[0082] The preparation method of above-mentioned functionalized graphene is as follows:

[0083] (A) Graphene oxide, sodium hydroxide and water were mixed through an ultrasonic cell disruptor for 50 minutes to obtain a graphene oxide mixture, wherein the mass percentage of graphene oxide in the graphene oxide mixture was 0.25%;

[0084] (B) mixing the...

Embodiment 2

[0091] The present embodiment provides an antistatic graphene latex slurry and a preparation method thereof, wherein the antistatic graphene latex slurry comprises the following components in parts by weight: 75 parts of natural latex, 2 parts of benzoyl peroxide, acetylene 3 parts of carbon black, 6 parts of functionalized graphene, 1 part of N-oxydiethylene-2-benzothiophene sulfenamide, 2 parts of N-isopropyl-N′-phenyl-p-phenylenediamine and water 10 copies;

[0092] The functionalized graphene includes the following raw material components in mass percentage: 15% graphene oxide, 7% potassium hydroxide, 8% octadecylamine and 70% trisodium citrate.

[0093] The preparation method of above-mentioned functionalized graphene is as follows:

[0094](A) Graphene oxide, potassium hydroxide and water were mixed through an ultrasonic cell disruptor for 40 minutes to obtain a graphene oxide mixture, wherein the mass percentage of graphene oxide in the graphene oxide mixture was 0.2%;...

Embodiment 3

[0102] The present embodiment provides a kind of antistatic graphene latex slurry and preparation method thereof, and described antistatic graphene latex slurry comprises the component of following parts by weight: 70 parts of natural latex, 1-bis(tert-butyl peroxy )-3,3,5-trimethylcyclohexane 3 parts, carbon nanotubes 5 parts, functionalized graphene 2 parts, N-oxydiethylene-2-benzothiophene sulfenamide 3 parts, 2 , 2 parts of 2,4-trimethyl-1,2-dihydroquinoline polymer and 18 parts of water;

[0103] The functionalized graphene includes the following raw material components in mass percentage: 8% graphene oxide, 2% sodium hydroxide, 5% octadecylamine and 85% ascorbic acid.

[0104] The preparation method of above-mentioned functionalized graphene is as follows:

[0105] (A) Graphene oxide, sodium hydroxide and water were mixed for 60 min through an ultrasonic cell disruptor to obtain a graphene oxide mixture, wherein the mass percentage of graphene oxide in the graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com