A kind of worm-like tin oxide gas-sensing material and its preparation method and ethanol detection application

A gas-sensitive material, tin oxide technology, applied in tin oxide, nanotechnology for materials and surface science, material resistance, etc., can solve the problems of expensive raw materials, long preparation cycle, and low purity of products, and achieve the preparation method Ease of operation, short response time, and high sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) get 50 milliliters of hydrogen peroxide solution with mass concentration of 30%, add 1 milliliter of concentrated nitric acid to it, add 0.3 gram of tin particles after mixing, and react at 80 ° C for 48 hours;

[0033] (2) the powder obtained in step (1) was collected by centrifugation, washed with deionized water for 3 times, and dried in an oven at 60°C overnight;

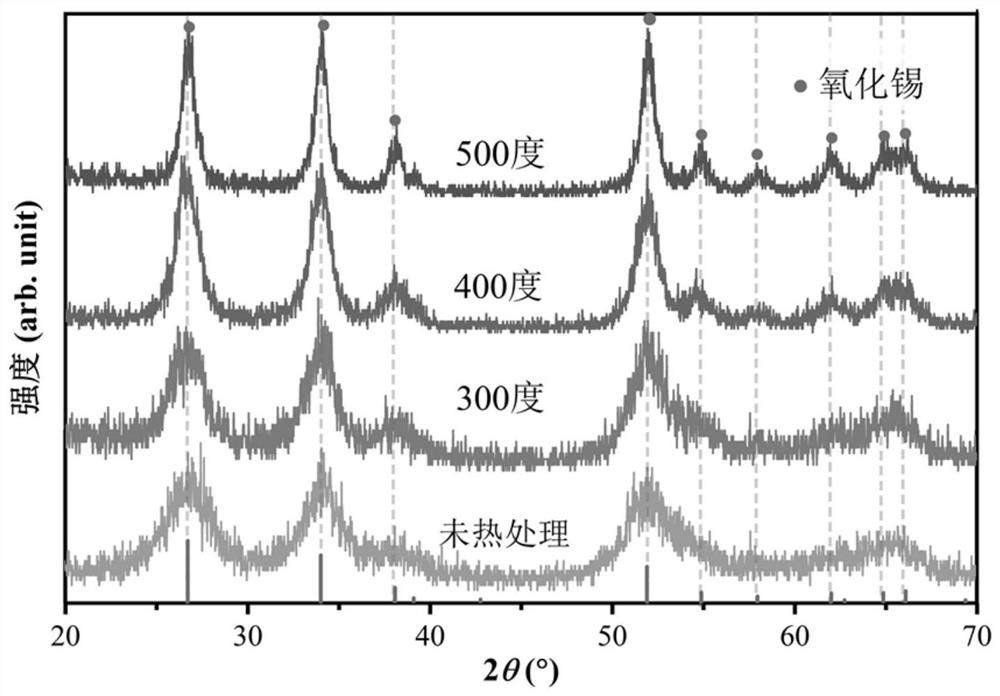

[0034] (3) heat treating the powder obtained in step (2) at 300° C. for 2 hours to obtain a worm-like tin oxide gas-sensing material;

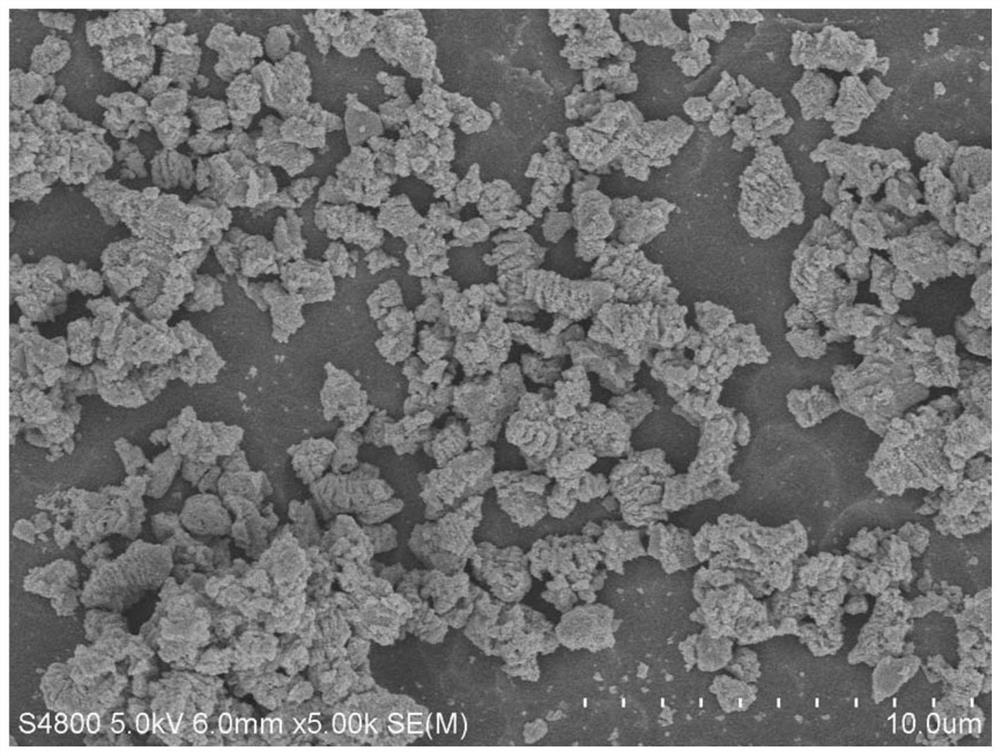

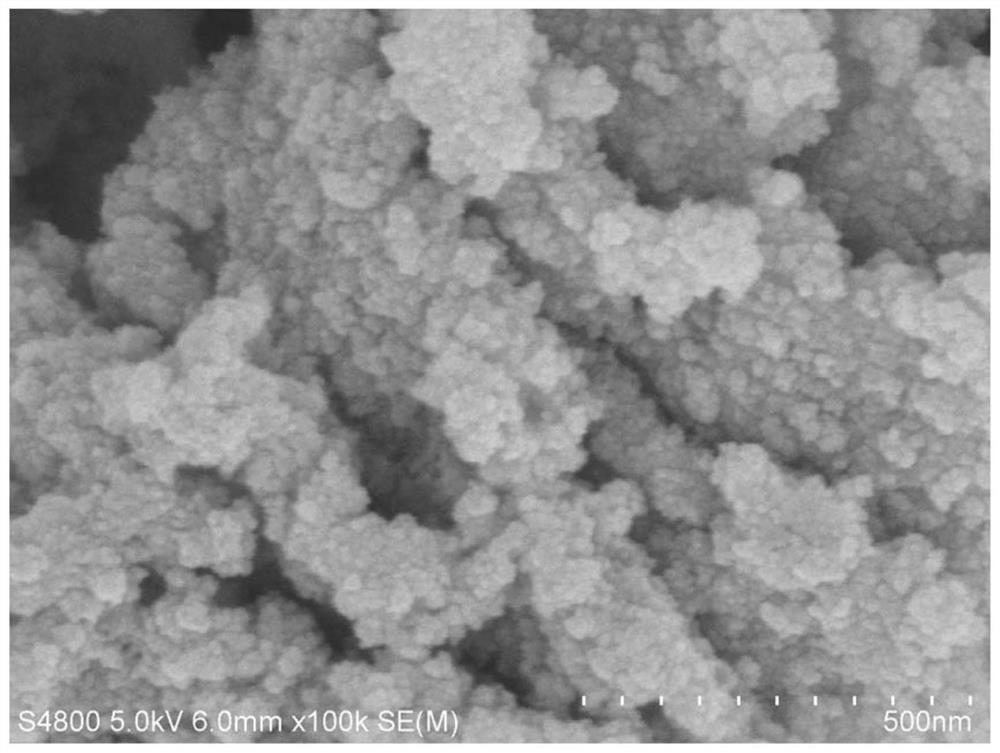

[0035] Depend on figure 1 The low magnification scanning electron microscope photo shows that the tin oxide is worm-like and has good dispersion. pass figure 2 It can be seen from the high-magnification scanning electron microscope photo of a single tin oxide particle that the tin oxide particle obtained by the present invention is a worm-like particle composed of a tin oxide lamellar structure, and the tin oxide lamellar structure is composed of tin oxide nanopart...

Embodiment 2

[0037] (1) step (1) with embodiment 1;

[0038] (2) step (2) with embodiment 1;

[0039] (3) heat treatment of the powder obtained in step (2) at 400° C. for 2 hours to obtain a worm-like tin oxide gas-sensing material ( Figure 4 shown).

Embodiment 3

[0041] (1) step (1) with embodiment 1;

[0042] (2) step (2) with embodiment 1;

[0043] (3) heat treatment of the powder obtained in step (2) at 500° C. for 2 hours to obtain a worm-like tin oxide gas-sensing material ( Figure 5 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com