Photoresponse magnetic nano-particles with wettability reversible conversion and preparation method of photoresponse magnetic nano-particles

A magnetic nanoparticle, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as environmental hazards, difficult biodegradation, low surface free energy, etc., and achieve environmental pollution. Small, improve the effect of easy agglomeration and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

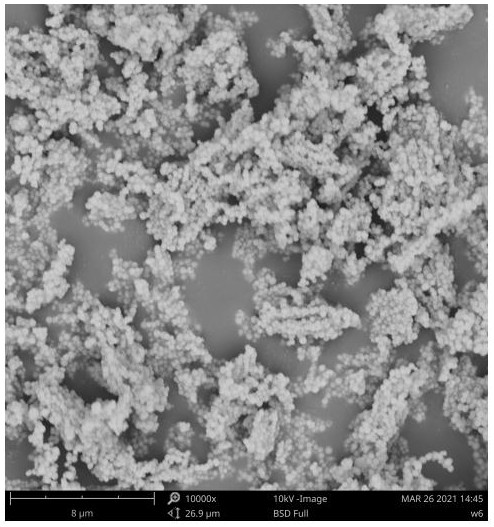

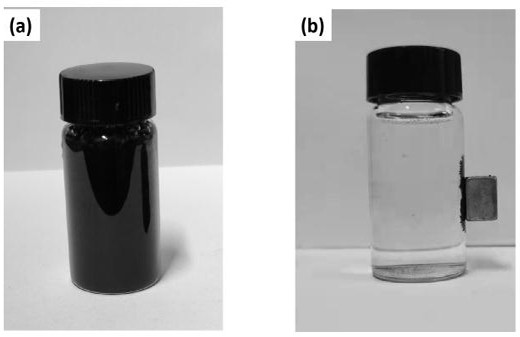

[0033] (1) Weigh 1.08 g FeCl 3 ·6H 2 O and 3.0 g of sodium acetate were dissolved in 30 mL of ethylene glycol. After stirring at room temperature for 30 min, the mixed solution was transferred to a high-pressure reactor and placed in an oven with the temperature set at 200 ° C. After 8 h of reaction , after the autoclave is cooled to room temperature, the Fe 3 o 4 The magnetism was used for solid-liquid separation and washed with deionized water and ethanol three times each. After cleaning, put it into 50 ℃ vacuum drying for 10 h to obtain dry black Fe 3 o 4 nanoparticles.

[0034] (2) Weigh 0.1 g Fe 3 o 4 Particles were dispersed in a mixture of 40 mL of absolute ethanol and 10 mL of deionized water. After ultrasonic dispersion for 30 min, 2.5 mL of ammonia water was added and placed on a magnetic stirrer to stir for 10 min. Measure 200 μL of TEOS into 10 mL of absolute ethanol, and transfer it to the Fe 3 o 4 In the dispersion of particle ethanol and deionized wate...

Embodiment 2

[0043] (1) Weigh 1.08 g FeCl 3 ·6H 2 O and 3.0 g of sodium acetate were dissolved in 30 mL of ethylene glycol, and after stirring for 1 h at room temperature, the mixed solution was transferred to a high-pressure reactor and placed in an oven with the temperature set at 160 °C. , after the autoclave is cooled to room temperature, the Fe 3 o 4 The magnetism was used for solid-liquid separation and washed with deionized water and ethanol three times each. After cleaning, put it into 50 ℃ vacuum drying for 10 h to obtain dry black Fe 3 o 4 nanoparticles.

[0044] (2) Weigh 0.1 g Fe 3 o 4 Particles were dispersed in a mixture of 10 mL of absolute ethanol and 10 mL of deionized water. After ultrasonic dispersion for 30 min, 2.5 mL of ammonia water was added and placed on a magnetic stirrer to stir for 10 min. Measure 100 μL of TEOS into 10 mL of absolute ethanol, and transfer it to the Fe 3 o 4 In the dispersion of particle ethanol and deionized water, stirring was contin...

Embodiment 3

[0048] (1) Weigh 1.08 g FeCl 3 ·6H 2 O and 3.0 g of sodium acetate were dissolved in 30 mL of ethylene glycol, and after stirring at room temperature for 30 min, the mixed solution was transferred to a high-pressure reactor and placed in an oven with the temperature set at 200 °C. , after the autoclave is cooled to room temperature, the Fe 3 o 4 The magnetism was used for solid-liquid separation and washed with deionized water and ethanol three times each. After cleaning, put it into 50 ℃ vacuum drying for 10 h to obtain dry black Fe 3 o 4 nanoparticles.

[0049] (2) Weigh 0.1 g Fe 3 o 4 Particles were dispersed in a mixture of 30 mL of absolute ethanol and 15 mL of deionized water. After ultrasonic dispersion for 30 min, 2.5 mL of ammonia water was added and placed on a magnetic stirrer to stir for 10 min. Measure 100 μL of TEOS into 10 mL of absolute ethanol, and transfer it to the Fe 3 o 4 In the dispersion of particle ethanol and deionized water, stirring was con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com