Thermosetting phenolic resin and preparation method, regeneration method and recovery method thereof

A phenolic resin, thermosetting technology, applied in the field of thermosetting phenolic resin and its preparation, can solve the problems of low commercial value, environmental pollution, high energy consumption, etc., and achieves a simple, green, and controllable method suitable for large-scale industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of thermosetting phenolic resin provided by the invention comprises:

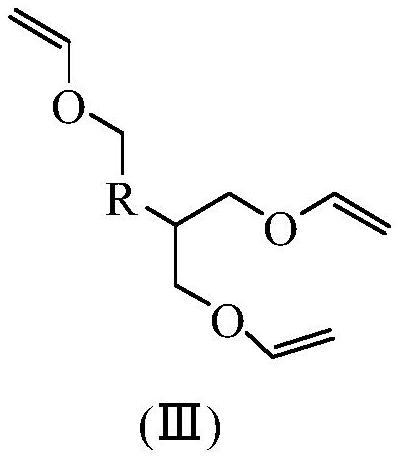

[0029] S1, provide phenolic resin and curing agent, wherein, described phenolic resin contains phenolic hydroxyl group, and described curing agent is the derivative of alcohol, and the derivative of described alcohol contains more than 2 vinyl ether functional groups (-O-CH= CH 2 );

[0030] S2, mixing the phenolic resin with the curing agent to obtain a thermosetting phenolic resin after curing, wherein the thermosetting phenolic resin contains an acetal functional group.

[0031] In step S1, the structural formula of the phenolic resin is shown in the following formula (I), which has unreacted phenolic hydroxyl groups to ensure the processability of the phenolic resin,

[0032] n≥2.

[0033] At the same time, in order to further improve the processability of the phenolic resin and the curing agent, the phenolic resin is preferably at least one of a novolac resin and a br...

Embodiment 1

[0074] 1 mol of novolak resin and 1 mol of 1,4-cyclohexanedimethanol divinyl ether were mixed and precured at 100° C. for 30 minutes to obtain a precured product. The pre-cured product was processed by a flat vulcanizing machine at 150° C. and 10 MPa for 20 minutes, and then cured in a vacuum oven at 160° C. for 2 hours to obtain the first thermosetting phenolic resin.

[0075] The first thermosetting phenolic resin was processed by a flat vulcanizing machine at 170° C. and 10 MPa for 30 minutes to obtain the second thermosetting phenolic resin.

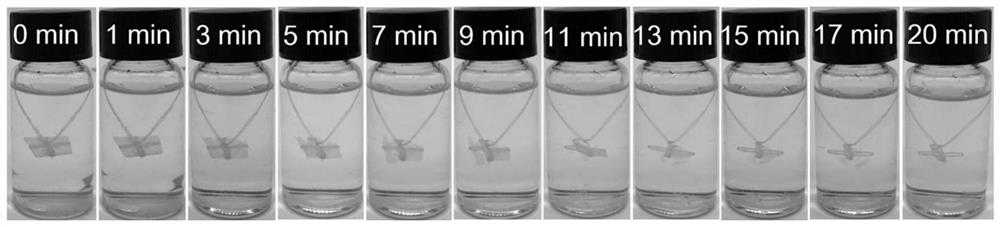

[0076] The first thermosetting phenolic resin was hydrolyzed in a 0.1 M hydrochloric acid acetone mixed solution (pH=1), and the phenolic resin and 1,4-cyclohexanedimethanol were recovered. The recovered phenolic resin is re-crosslinked with 1,4-cyclohexanedimethanol divinyl ether to obtain a third thermosetting phenolic resin.

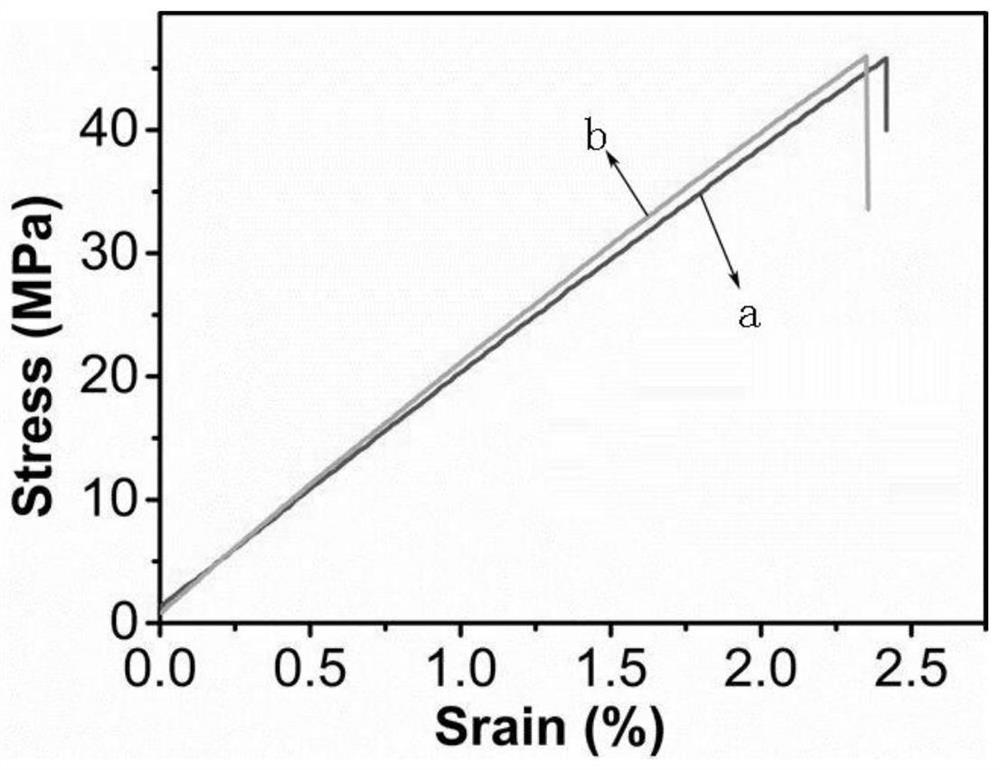

[0077] After testing, the glass transition temperature of the first thermosetting phenolic resin is 106°...

Embodiment 2

[0083] 1 mol of novolak resin and 0.5 mol of 1,4-cyclohexanedimethanol divinyl ether were mixed and precured at 100° C. for 30 minutes to obtain a precured product. The pre-cured product was processed by a flat vulcanizing machine at 150° C. and 10 MPa for 20 minutes, and then cured in a vacuum oven at 160° C. for 2 hours to obtain the first thermosetting phenolic resin.

[0084] The first thermosetting phenolic resin was processed by a flat vulcanizing machine at 150° C. and 10 MPa for 20 minutes to obtain the second thermosetting phenolic resin.

[0085] The first thermosetting phenolic resin was hydrolyzed in a 0.1 M hydrochloric acid acetone mixed solution (pH=1), and the phenolic resin and 1,4-cyclohexanedimethanol were recovered. The recovered phenolic resin is re-crosslinked with 1,4-cyclohexanedimethanol divinyl ether to obtain a third thermosetting phenolic resin.

[0086] Compared with the thermosetting phenolic resin in Example 1, the first thermosetting phenolic r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com