Preparation method of micro-nano lignocellulose composite material, composite material and application

A technology of lignocellulose and composite materials, which is applied in the field of preparation of micro-nano lignocellulose composite materials, can solve the problems of limiting the high-value utilization of lignocellulose, cumbersome grafting modification steps, and low reaction efficiency, and achieves good results. The effects of organic solvent dispersibility, easy operation of the method, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

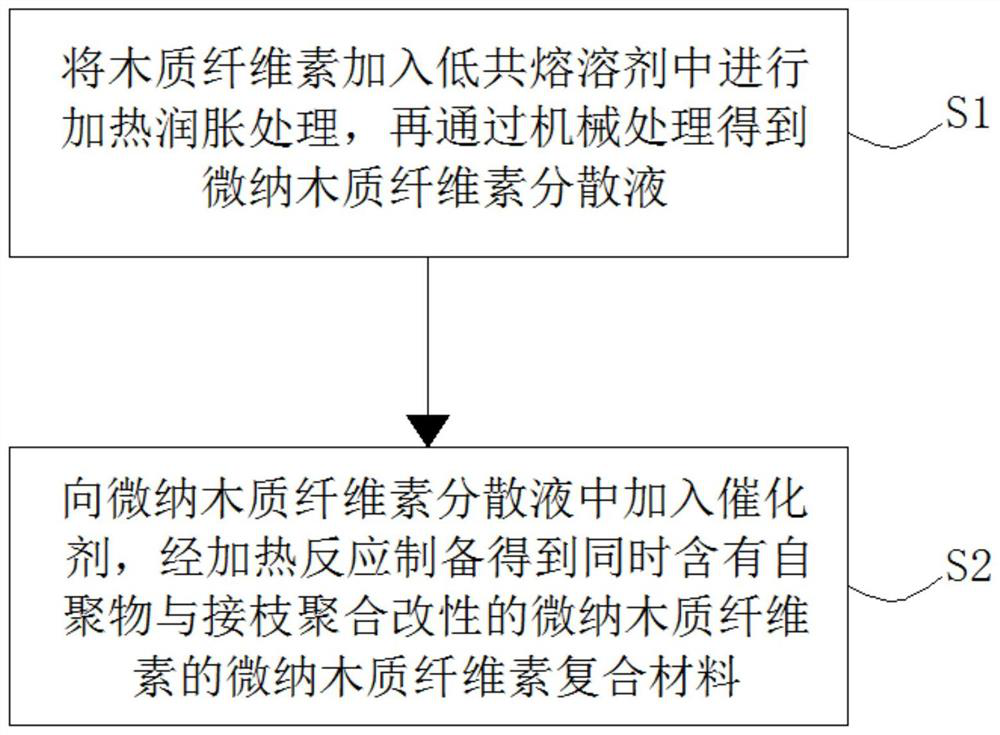

[0038] Now in conjunction with accompanying drawing and specific embodiment the present invention is further described, as figure 1 As shown, according to the preparation method of the micro-nano lignocellulose composite material of the embodiment of the present invention, the method comprises the following steps:

[0039] S1, adding lignocellulose into a deep eutectic solvent for heating and swelling treatment, and then mechanically treating to obtain a micro-nano lignocellulose dispersion;

[0040] S2. Adding a catalyst to the micro-nano lignocellulose dispersion liquid, and preparing a micro-nano lignocellulose composite material containing self-polymer and graft polymerization-modified micro-nano lignocellulose through heating reaction.

[0041] In one embodiment, a polymerizable monomer is added to the micro-nano lignocellulose dispersion before the heating reaction.

[0042]In one embodiment, the polymerizable monomer includes but is not limited to at least one of acryl...

Embodiment 1

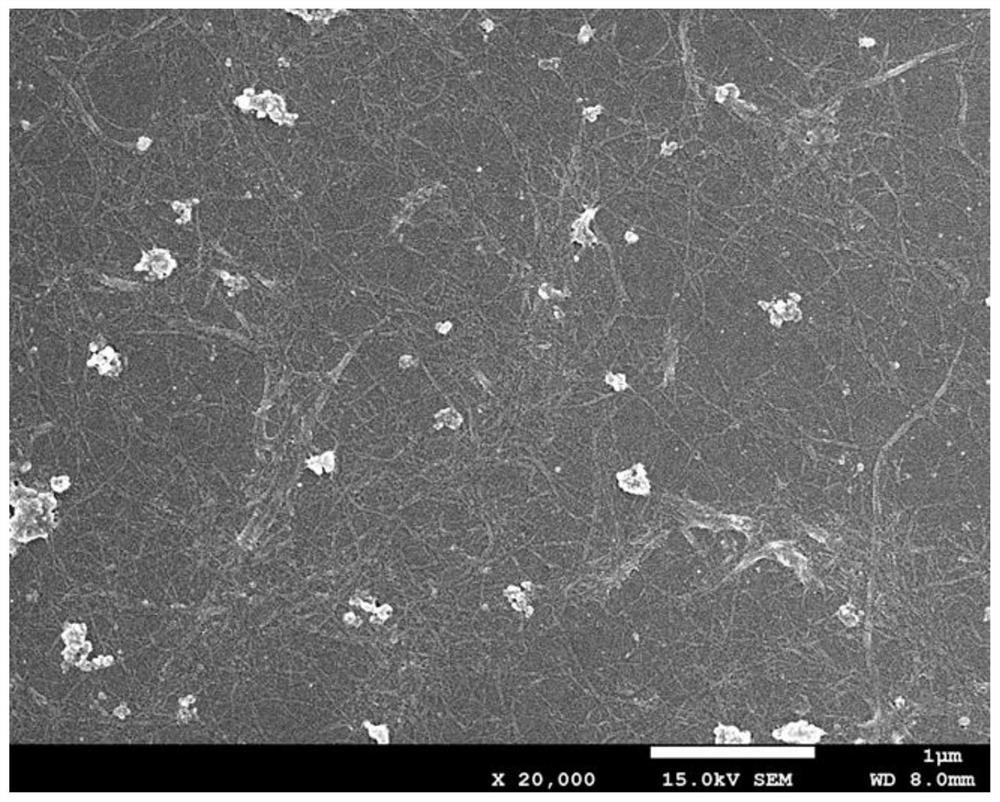

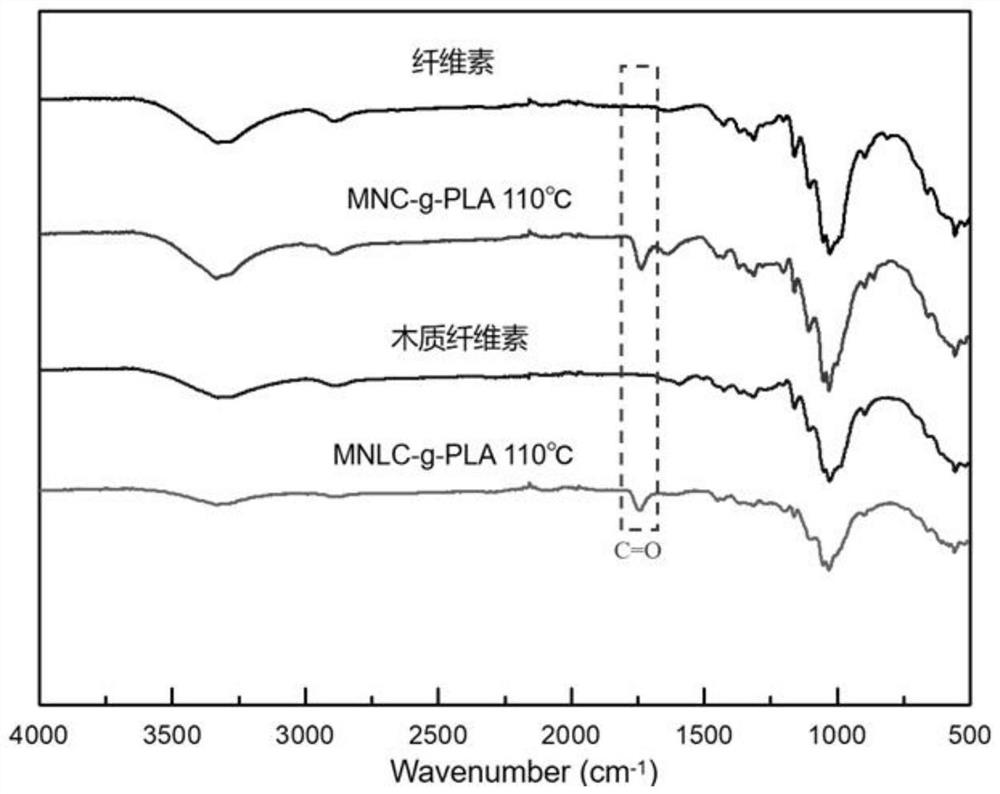

[0057] Take 3g of absolute dry cellulose, the lignin content is 0%, and it is decomposed into cotton flocs through a decomposer; the decomposed cellulose and lactic acid / choline chloride deep eutectic solvent are at a solid-to-liquid ratio of 1:8 (g / mL) were mixed evenly, heated and swelled in an oil bath at 100°C for 3 hours; the swollen cellulose was ground in a colloid mill for 40 minutes to obtain a micro-nanocellulose deep eutectic solvent dispersion with a diameter of 5nm- 40nm; Slowly add 2.5wt% stannous octoate catalyst relative to the mass of lactic acid to the dispersion, heat the dispersion in an oil bath at 100°C for 8 hours and stir mechanically to obtain a deep eutectic solvent autopolymer and graft polymerization modification Micro-nano cellulose mixture dispersion, the obtained mixture dispersion of deep eutectic solvent self-polymer and graft polymerization modified micro-nano cellulose can be processed into a composite material through a 3D printing process. ...

Embodiment 2

[0059] Get 3g of absolute dry lignocellulose, lignin content is 5.76%, decompose to cotton-wool shape through decomposer; The lignocellulose after decompression and lactic acid / choline chloride deep eutectic solvent are 1:10 ( g / mL) were mixed evenly, heated and swelled in an oil bath at 90°C for 1 h; the swollen lignocellulose was ground in a colloid mill for 40 min to obtain micro-nano lignocellulose deep eutectic solvent dispersion, micro-nano lignocellulose The diameter of the element is 5nm-40nm; slowly add 2.5wt% stannous octoate catalyst relative to the mass of lactic acid to the dispersion, heat the dispersion in an oil bath at 110°C for 12h and mechanically stir to obtain a deep eutectic solvent autopolymer and Graft polymerization modified micro-nano lignocellulose mixture dispersion, the prepared deep eutectic solvent autopolymer and graft polymerization modified micro-nano lignocellulose mixture dispersion can be processed into composite materials through injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com