Composite passivation solution and preparation method thereof

A technology of passivation solution and solution, which is applied in the field of metal anti-corrosion, can solve problems such as unsatisfactory substrate adhesion, insufficient performance advantages, complex production process, etc., to ensure the feasibility of preparation, avoid hidden dangers of cancer, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

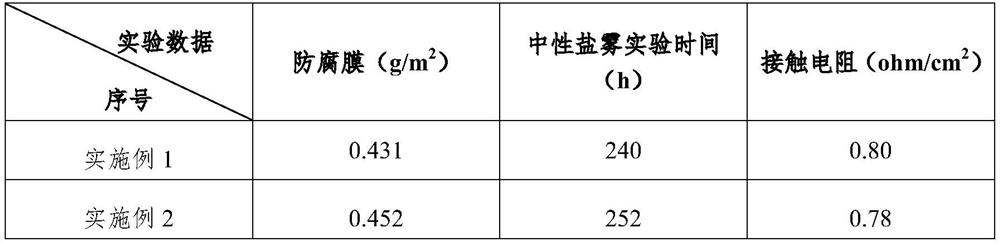

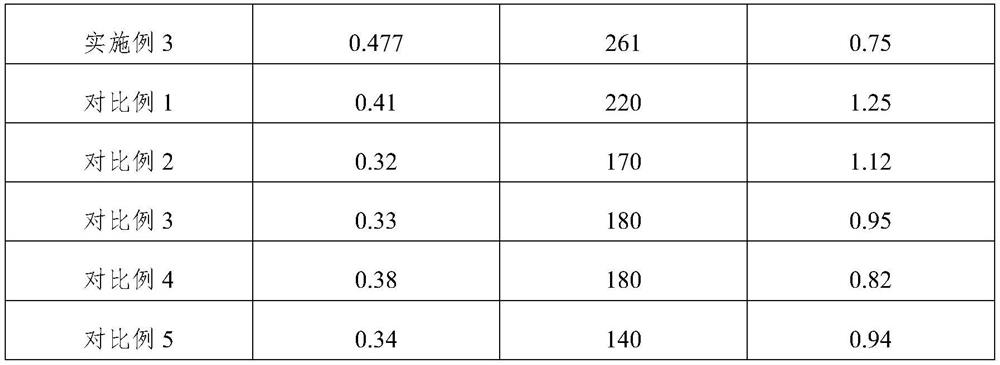

Embodiment 1

[0020] A composite passivation solution comprising the following components by weight: 0.5 parts of graphene oxide, 20 parts of cobalt salt, 8 parts of chelating agent, 30 parts of polar solvent, 10 parts of organic volatile solvent, and the cobalt salt contains Co 2+ A water-soluble inorganic salt of ions, and the pH of the composite passivation solution is 2.

[0021] The preferred technical solution is that the chelating agent is ethylenediaminetetraacetic acid; the polar solvent is a mixed solution of distilled water and absolute ethanol, wherein the mass ratio of the two is 1:4; the organic volatile The neutral solvent is absolute ethanol; the cobalt salt is Co(NO 3 ) 2 ·7H 2 O.

[0022] The preparation method of above-mentioned a kind of composite passivation solution, comprises the following steps:

[0023] S1: Mix distilled water and absolute ethanol according to the mass ratio of 1:4, and adjust the pH to 3-4 with sulfuric acid to obtain a polar solvent;

[0024]...

Embodiment 2

[0028] A composite passivation solution, comprising the following components by weight: 1.5 parts of graphene oxide, 15 parts of cobalt salt, 5 parts of chelating agent, 45 parts of polar solvent, 20 parts of organic volatile solvent, and the cobalt salt contains Co 2+ A water-soluble inorganic salt of ions, and the pH of the composite passivation solution is 3.

[0029] The preparation method of the composite passivation solution in Example 2 is the same as that in Example 1.

Embodiment 3

[0031] A composite passivation solution, comprising the following components by weight: 2 parts of graphene oxide, 10 parts of cobalt salt, 2 parts of chelating agent, 70 parts of polar solvent, 30 parts of organic volatile solvent, and the cobalt salt contains Co 2+ The water-soluble inorganic salt of ion, the pH of described composite passivation solution is 4.

[0032] The preparation method of the composite passivation solution in Example 3 is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com