A method for preparing electrolyte film by pre-pressing assisted sintering, battery/electrolytic cell

An electrolyte film and assisted sintering technology, which is applied in the direction of electrolytic components, electrolytic processes, fuel cells, etc., can solve the problem of reduction and achieve the effect of simplified process, simple equipment, and consistent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

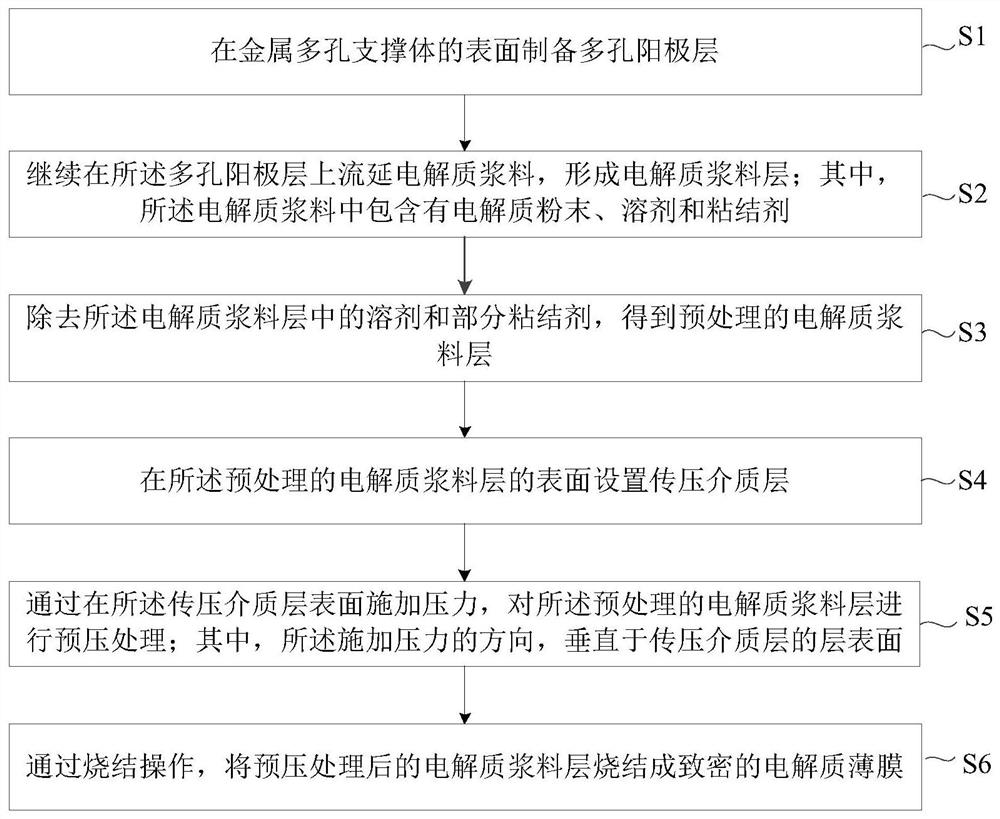

Method used

Image

Examples

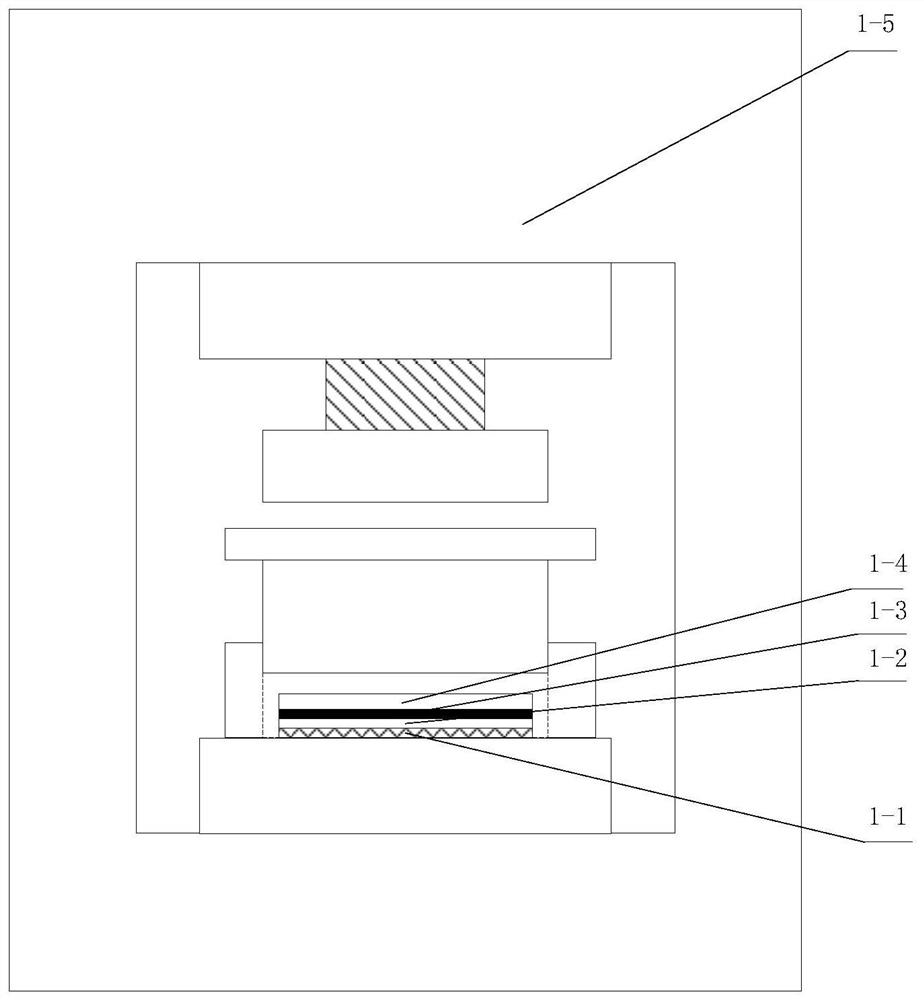

Embodiment 1

[0091] Using powder metallurgy method 10×10cm 2 The Cr-Fe support body, the Fe content is 10%, the porosity of the support body is guaranteed at 40%, after the surface of the support body is guaranteed to be flat, a layer of NiO-GDC with a certain amount of pore-forming agent is cast as the anode, the thickness is 50 μm. After drying, continue to cast a layer of GDC as electrolyte with a thickness of 30 μm. After drying, put it into a heating furnace for debinding treatment by slowly raising the temperature at 1-2°C / min to 200-300°C for 1h-2h. After debinding, add a layer of high-pressure polyethylene film on top of the electrolyte powder layer as a pressure transmission medium layer with a thickness of 1mm. Then the material is placed in the mold, and pressurized by a hydraulic press with a pressure of 250MPa. After pressurization, the anode and electrolyte are sintered, and the sintering temperature is 1350°C. After the sintering is completed, the test gas leakage rate m...

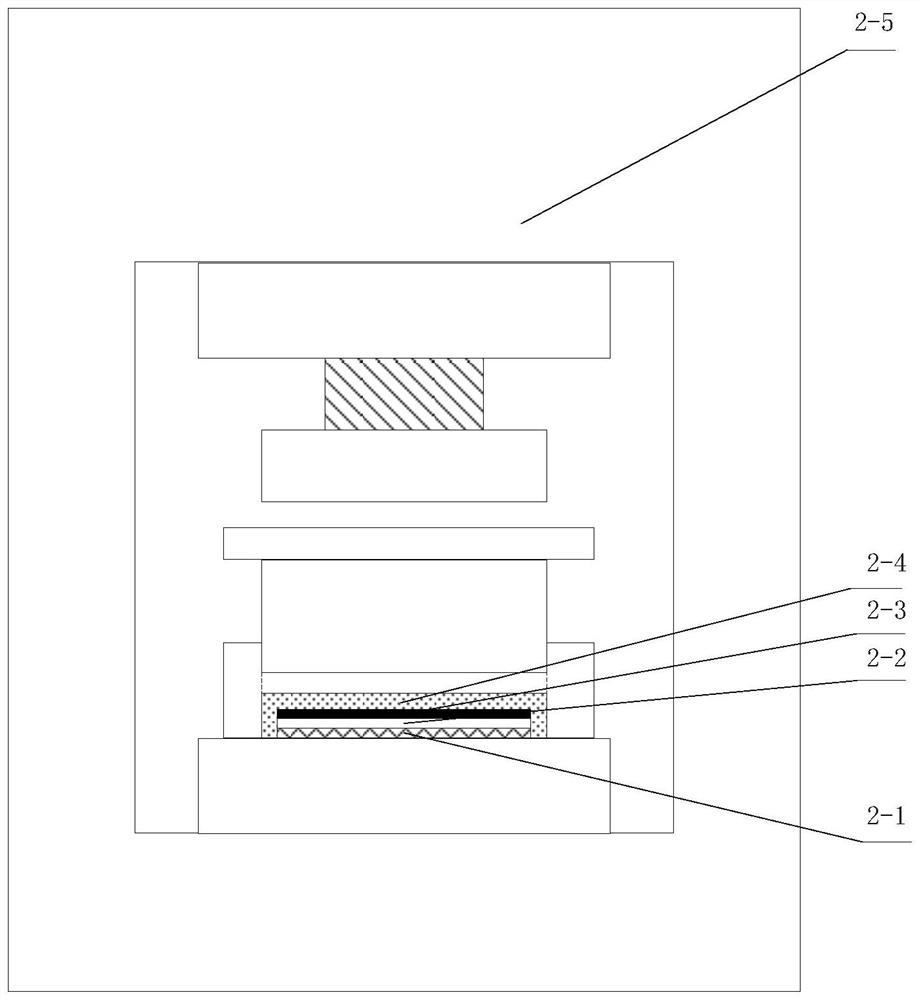

Embodiment 2

[0094] 10×20cm prepared by powder metallurgy 2 The Cr-based porous support body, the Fe content is 7%, the porosity of the support body is guaranteed to be 40%, after the surface of the support body is guaranteed to be smooth, a layer of NiO-ScSZ with a certain amount of pore-forming agent is cast as the anode, the thickness is 50 μm. After drying, continue to cast a layer of ScSZ (zirconia-based) as electrolyte with a thickness of 20 μm. After drying, put it into a heating furnace for debinding treatment by slowly raising the temperature at 1-2°C / min to 250°C for 1 hour. After debinding, add a layer of polyethylene film with a thickness of 0.5mm on top of the electrolyte powder layer as a pressure transmission medium layer, then place the material in the mold, and pressurize it with a hydraulic press at a pressure of 350MPa. After pressurization, the anode and electrolyte are sintered, and the sintering temperature is 1350°C. After the sintering is completed, the test gas ...

Embodiment 3

[0096] 15×15cm prepared by powder metallurgy 2 The ferritic stainless steel support body, the Cr content is 22%, the porosity of the support body is controlled at 40%, after the surface is smoothed, a layer of NiO-GDC with a certain amount of pore-forming agent is cast as the anode, and the thickness is 30 μm , sintered at 1100 ° C for 1 hour, and then continued to flow casting to prepare a Co-doped GDC electrolyte, and the thickness of the electrolyte slurry layer was 50 μm. After drying, put it into a heating furnace for debinding treatment by slowly raising the temperature at 1-2°C / min to 250°C for 1 hour. After debinding, a layer of polyamide film with a thickness of 1 mm is added on the electrolyte powder layer as a pressure transmission medium layer, and the above materials are placed in a hydraulic press for pressurization treatment with a pressure of 300 MPa. After pressurization, the anode and electrolyte are sintered, and the sintering temperature is 1050°C. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com