Nitraria tangutorum fruit ferment and preparation method thereof

A white thorn enzyme and thorn enzyme technology, which is applied to bacteria, food science, animal feed and other directions used in food preparation, can solve problems such as affecting the flavor and taste of enzymes, easy over-fermentation, and uncontrollable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

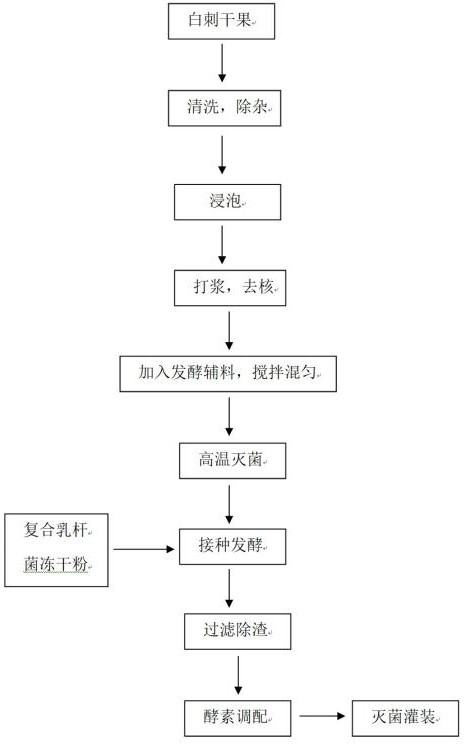

Image

Examples

Embodiment 1

[0034] A kind of Nitraria ferment, its preparation method is as follows:

[0035] (1) Preparation of Nitraria fruit pulp: Weigh a certain quality of Nitraria dried fruit, the solid-to-liquid ratio of the fruit pulp is 1:9, wash, soak in drinking tap water at about 40°C for 18 hours, then beat and remove the core, add 2% Whey powder, stirred and mixed evenly, natural pH, and the fruit pulp was boiled and sterilized at 100°C for 30 minutes;

[0036] (2) Fermentation: According to the mass ratio of 2:1:1:2, mix the strain freeze-dried powder of Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus casei, and Lactobacillus reuteri to obtain the freeze-dried powder of compound lactobacillus strains , according to the inoculum amount of 0.1wt%, inoculate into the Nitraria japonica pulp obtained in step (1), wherein the liquid content is 65wt%, and anaerobically ferment at 35° C. for 16 hours;

[0037] (3) Separation and deployment of enzyme: the fermentation product of ...

Embodiment 2

[0041] A kind of Nitraria ferment large-scale production technological process is as follows:

[0042] (1) Preparation of Nitraria fruit pulp: Weigh a certain quality of Nitraria dried fruit, the solid-to-liquid ratio is 1:4, wash and remove impurities, soak in distilled water at about 60°C for 12 hours, then beat the pulp and remove the core, and put it into an anaerobic fermentation tank , add 1% skim milk powder, stir and mix evenly, natural pH, and then boil and sterilize at 100°C for 30min;

[0043] (2) Fermentation: According to the mass ratio of 2:2:1:2, mix the strain freeze-dried powder of Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus casei, and Lactobacillus reuteri to obtain the freeze-dried powder of compound lactobacillus strains , according to the inoculum amount of 0.5wt%, inoculate into the Nitraria japonica pulp obtained in step (1), wherein the liquid content is 70wt%, and anaerobically ferment at 37° C. for 12 hours;

[0044] (3) Separat...

Embodiment 3

[0048] In the above-mentioned Examples 1-2, the pH value of the fermented liquid obtained in step (2) is detected, and a pH value within the range of 4.5-5.5 is considered as up to the standard of enzyme fermentation. The sensory evaluation of the fermentation result was carried out by comprehensive scoring method, and the sensory evaluation was as high as 9.2-9.5 points (out of 10 points).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com