4D printing device for titanium-nickel shape memory alloy and 4D printing component regulation and control method

A memory alloy and printing device technology, applied in the field of additive manufacturing, can solve problems such as cracks, limit the application of 4D printing titanium-nickel shape memory alloys, affect mechanical properties and use effects, etc., achieve good mechanical properties, inhibit the generation of cracks, Yield strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

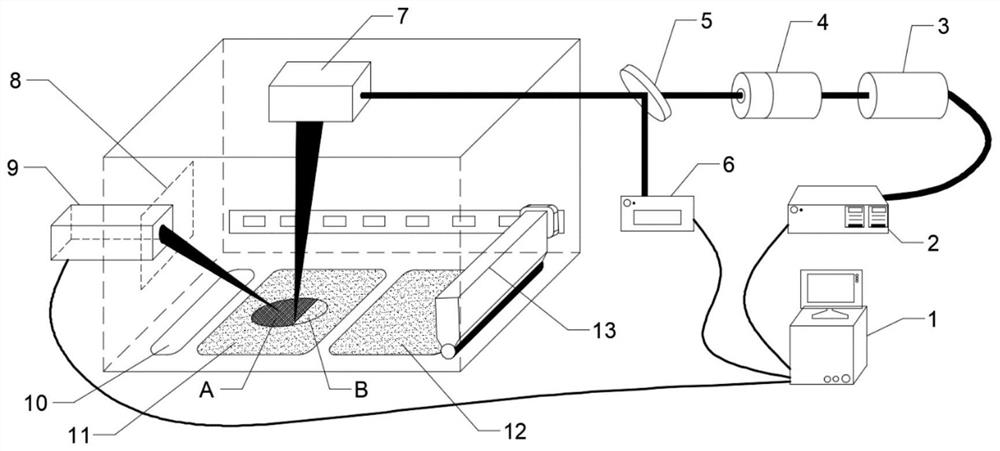

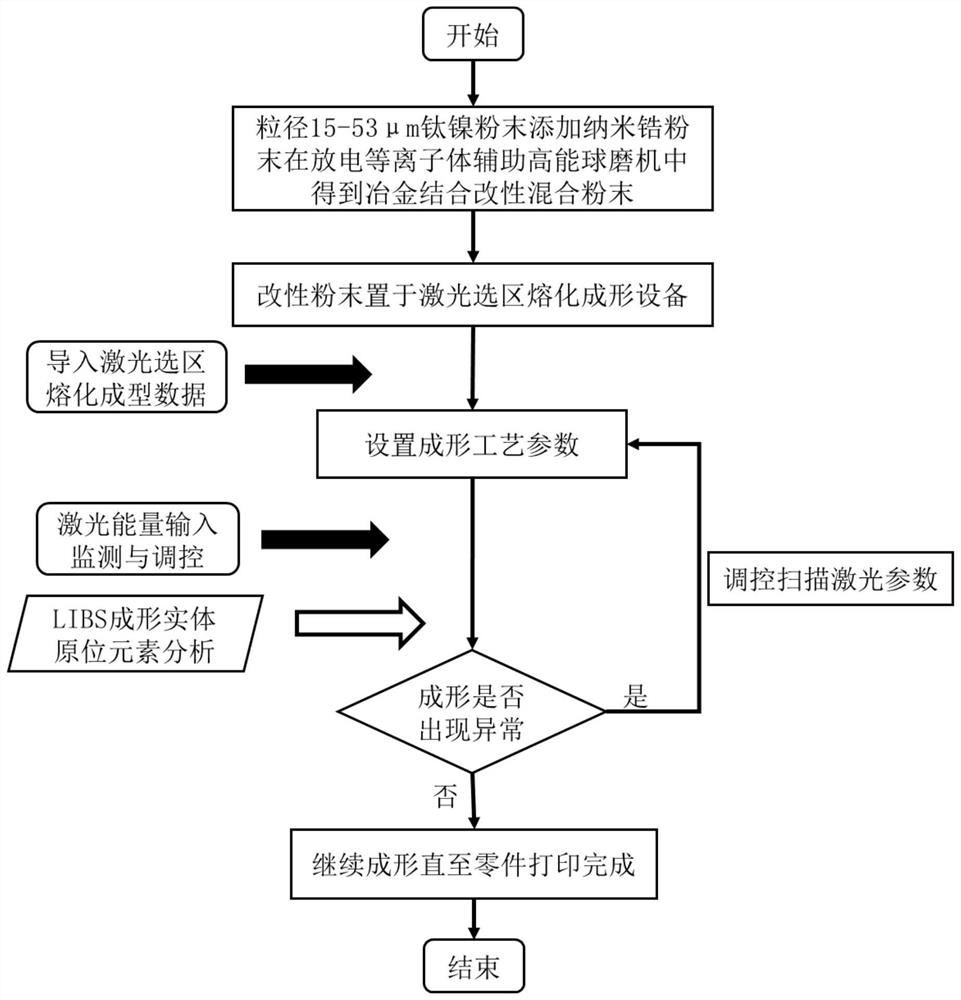

[0037] like Figure 1-2 shown. The invention discloses a 4D printing device of a titanium-nickel shape memory alloy, which includes a forming chamber, a collimating mirror 3, a focusing mirror 4, a high-speed scanning vibrating mirror 7 and an industrial computer 1, and the 4D printing device also includes a beam splitter 5. Laser input energy real-time monitor 6 and LIBS element non-destructive detector 9;

[0038] The beam splitter 5 is arranged on the laser optical path between the focusing mirror 4 and the high-speed scanning galvanometer 7; the beam splitter 5 is used to distribute a part of the laser light on the laser optical path to the laser input energy real-time monitor 6, That is, the laser input energy real-time monitor 6 collects the current laser power value through the beam splitter 5 and transmits it to the industrial computer 1, and compares it with the preset laser power value in the molding process. When the preset laser power value exceeds 1%, Perform fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com