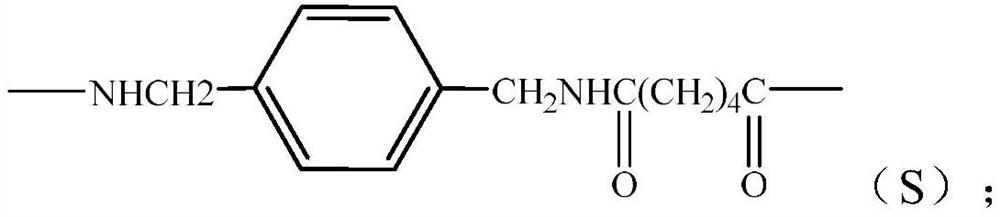

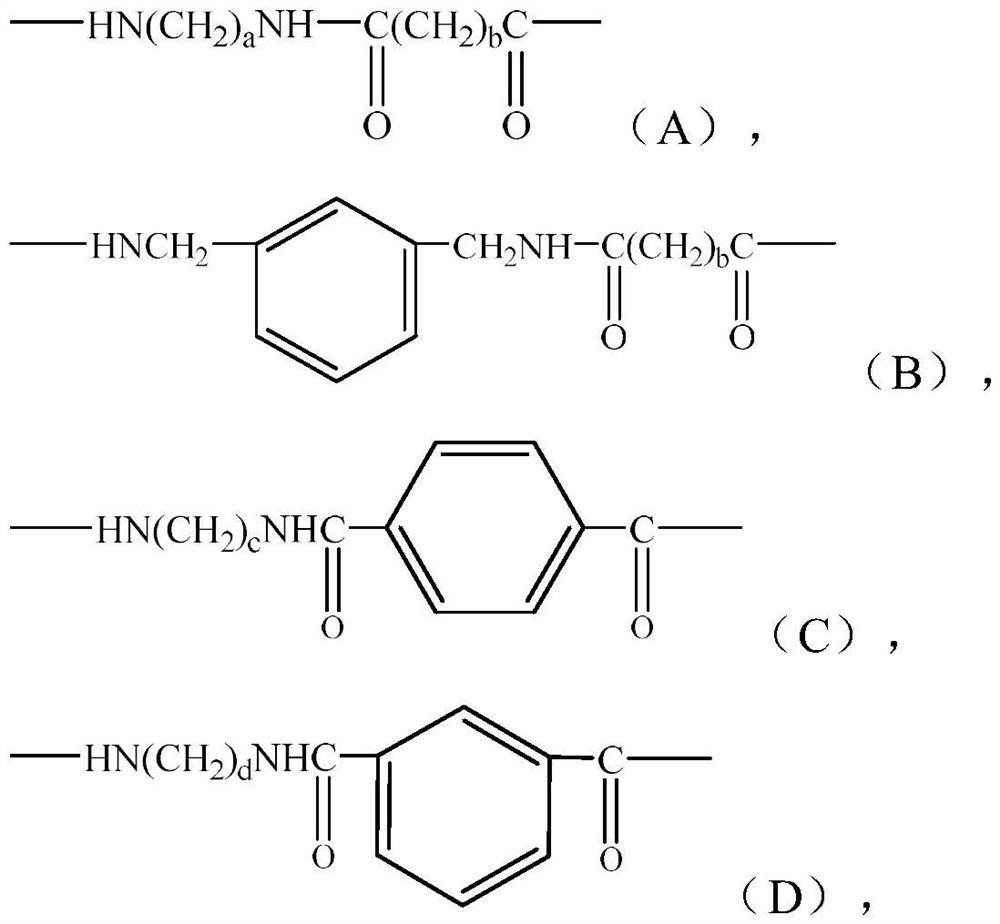

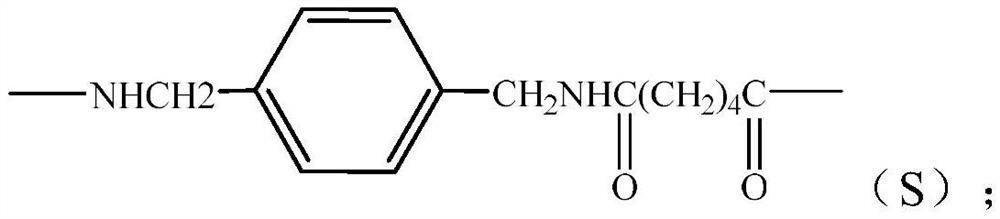

Semi-aromatic polyamide copolymer and preparation thereof

A semi-aromatic polyamide technology, applied in the field of semi-aromatic polyamide copolymers and its preparation, can solve the problems of poor processability and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A semi-aromatic polyamide copolymer obtained by polycondensation after mixing nylon salt Ⅰ and nylon salt Ⅱ in proportion. The degree of polymerization is 50-200. Hexamethylene adipamide salt is prepared by the following steps:

[0078] (1) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 80°C, replace nitrogen, and slowly add p-xylylenediamine dropwise until the adipic acid is completely dissolved until pH=7~7.5 , continue to react after 1 hour and stop to obtain a total of 29.1165 kg of adipyl p-xylylenediamine salt solution. After cooling, suction filter and dry to obtain 12.3145 kg of adipyl p-xylylenediamine salt for subsequent use.

[0079] (2) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 75°C, replace the nitrogen, and slowly add hexamethylenediamine dropwise until the adipic acid is completely disso...

Embodiment 2

[0082] A semi-aromatic polyamide copolymer obtained by polycondensation after mixing nylon salt Ⅰ and nylon salt Ⅱ in proportion. The degree of polymerization is 50-200. Hexamethylene adipamide salt is prepared by the following steps:

[0083] (1) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 80°C, replace nitrogen, and slowly add p-xylylenediamine dropwise until the adipic acid is completely dissolved until pH=7~7.5 , continue to react after 1 hour and stop to obtain a total of 29.1165 kg of adipyl p-xylylenediamine salt solution. After cooling, suction filter and dry to obtain 12.3145 kg of adipyl p-xylylenediamine salt for subsequent use.

[0084] (2) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 75°C, replace the nitrogen, and slowly add hexamethylenediamine dropwise until the adipic acid is completely disso...

Embodiment 3

[0087] A semi-aromatic polyamide copolymer obtained by polycondensation after mixing nylon salt Ⅰ and nylon salt Ⅱ in proportion. The degree of polymerization is 50-200. Hexamethylene adipamide salt is prepared by the following steps:

[0088](1) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 80°C, replace nitrogen, and slowly add p-xylylenediamine dropwise until the adipic acid is completely dissolved until pH=7~7.5 , continue to react after 1 hour and stop to obtain a total of 29.1165 kg of adipyl p-xylylenediamine salt solution. After cooling, suction filter and dry to obtain 12.3145 kg of adipyl p-xylylenediamine salt for subsequent use.

[0089] (2) Add 15kg of distilled water and 7.3070kg of adipic acid into the salt forming kettle, start stirring and raise the temperature to 75°C, replace the nitrogen, and slowly add hexamethylenediamine dropwise until the adipic acid is completely dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com